Multi-stage process quality forecast method based on hybrid MPLS

A process quality, multi-stage technology, applied in program control, electrical program control, comprehensive factory control, etc., can solve problems such as length inequality, achieve accurate quality prediction, and achieve the effect of process monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

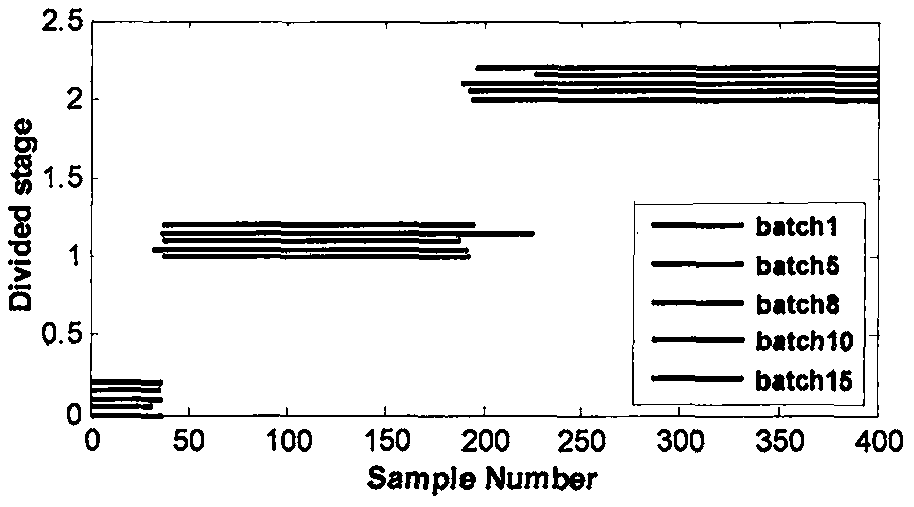

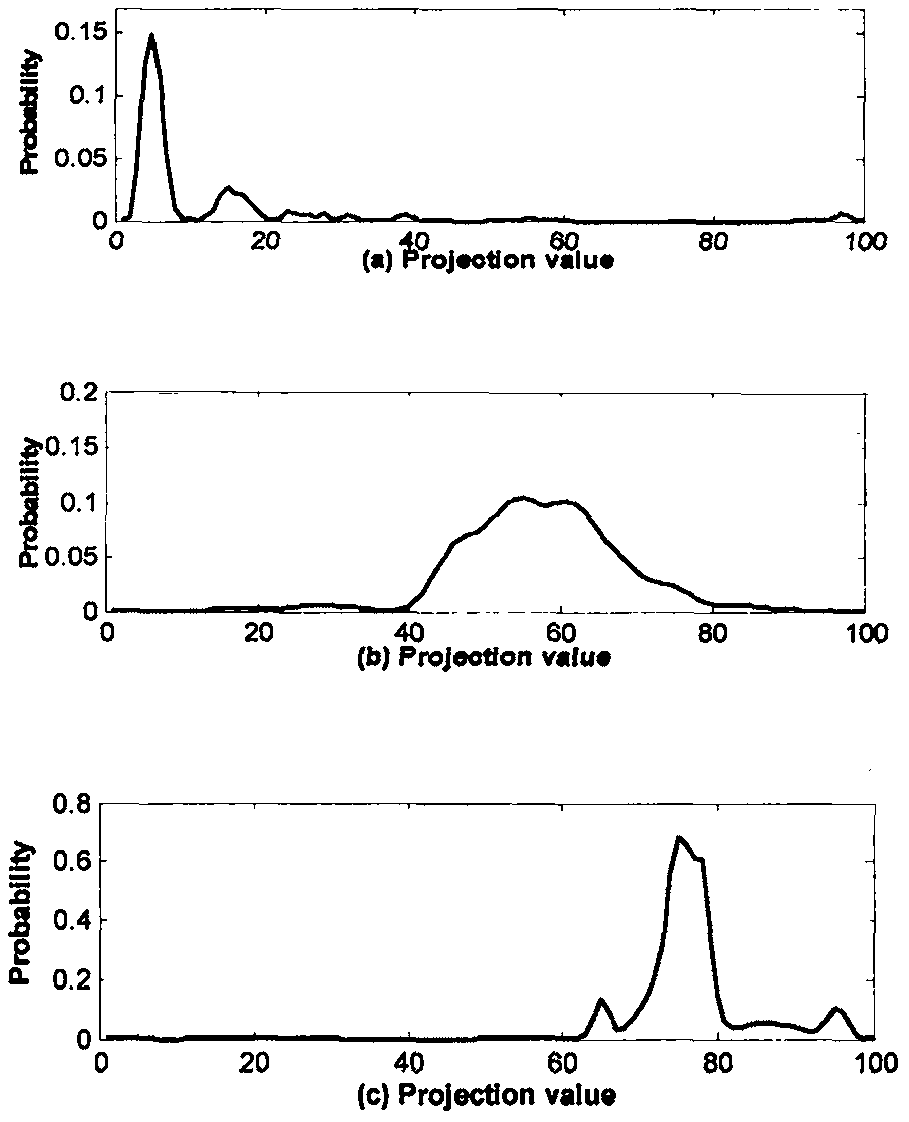

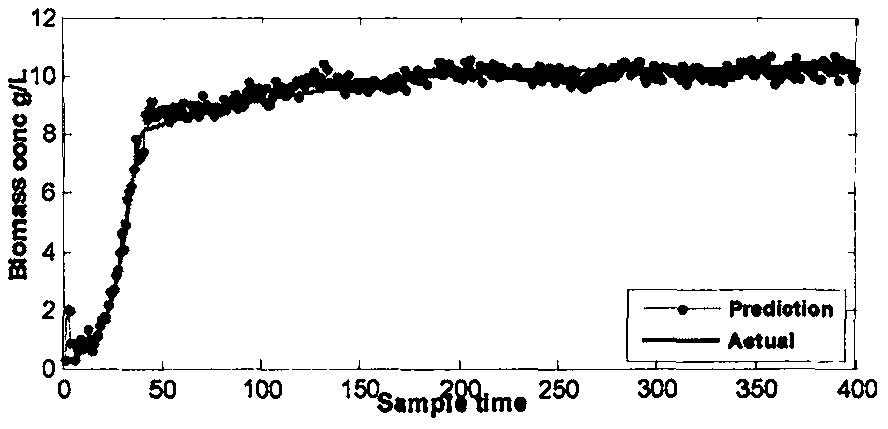

[0036]In the present invention, a Gaussian mixture model with better statistical distribution is introduced to identify and cluster the multi-sub-stage data sets of the industrial process, and MPLS models are respectively established in each sub-stage data set, and the models of each sub-stage are fused according to the Bayesian principle. Quality prediction, this method realizes more accurate quality prediction on the basis of multi-directional partial least squares. Partial least squares (PLS) is an important method in multivariate statistical analysis. PLS focuses on the relationship between multidimensional matrices X and Y to find the optimal low-dimensional feature interpretation direction. This optimization is based on the input space to In the sense of the predictive power of the output space. Multidirectional Partial Least Squares (MPLS) is an extension of PLS, which uses multiple batches of historical process data matrix X (I×J×K) and quality data matrix Y (I×M×K) to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com