Improved ELM algorithm-based capillary quality forecasting method

A capillary and quality technology, applied in the field of quality prediction in the field of regression technology, can solve problems such as instability and noise interference ELM model prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

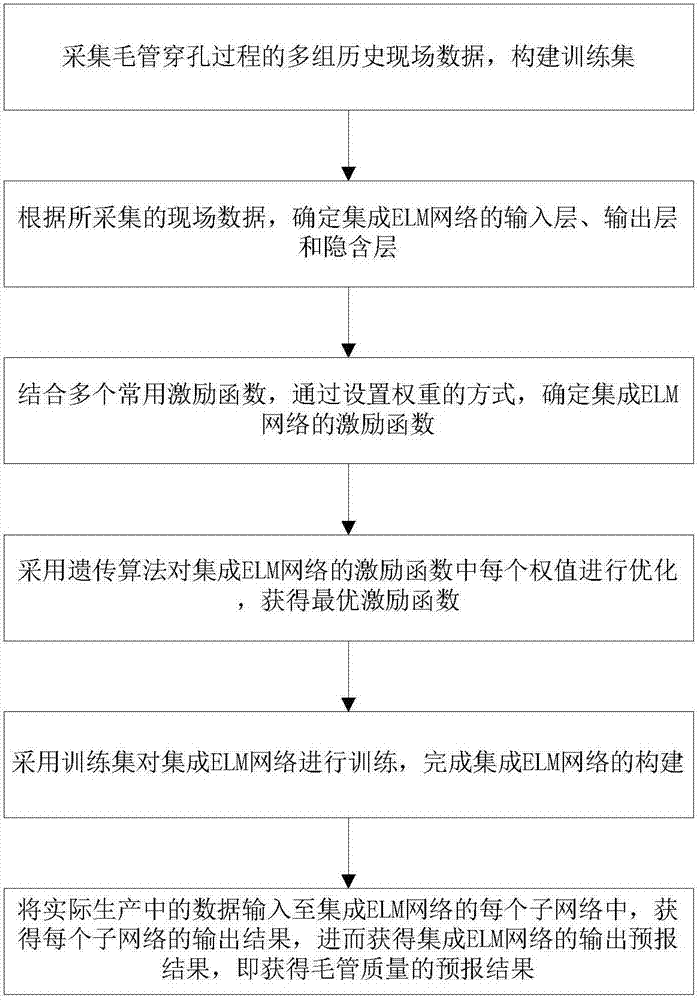

[0043] In the embodiment of the present invention, the capillary quality prediction method based on the improved ELM algorithm, the method flow chart is as follows figure 1 shown, including the following steps:

[0044] Step 1. Collect 40 sets of historical field data of the capillary perforation process to build a training set;

[0045] In the embodiment of the present invention, the actual measurement history data of the SWW skew rolling piercer of Baosteel Steel Tube Branch Company is used as a sample, and a total of 40 sets of data are used as training data. value, upper roller current, lower roller current, upper roller magnetic field, lower roller magnetic field, upper roller motor induced electromotive force, lower roller motor induced electromotive force, actual position of thrust trolley, upper roller lower actual value, lower roller upper ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com