Simple cutter sharpening device

A knife sharpening device and simple technology, applied in the direction of grinding drive device, grinding frame, grinding machine bed, etc., can solve the problems of rough surface of cutting material, affecting product quality, easy blunt belt knife, etc. The effect of the knife is good, the sharpening action is flexible, and the time is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

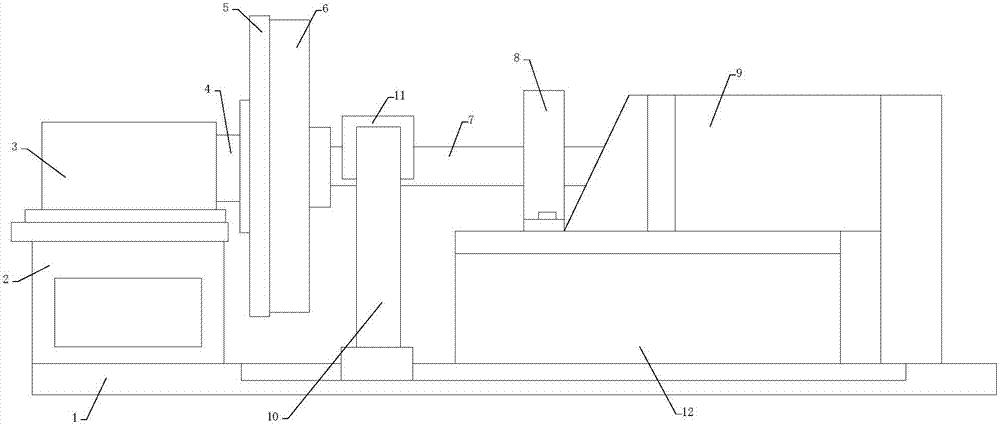

[0022] Such as figure 1 As shown, a simple knife sharpening device includes a whetstone 6, a fixing device and a driving device. The fixing device includes a base 1, a bearing 4 seat 3, a left bracket 2 and a right bracket 12. Above one end of the base 1 A left bracket 2 is provided, and a bearing 4 seat 3 is arranged above the left bracket 2, and a grindstone 6 is also arranged above the base 1, and the grindstone 6 is connected with the bearing 4 seat 3, and the base 1. A right bracket 12 is provided above the other end;

[0023] Described driving device comprises driving motor 9 and driving rod 7, and described driving motor 9 is arranged on right support 12 tops, and one end of described driving rod 7 links to each other with driving motor 9, and the other end of described driving rod 7 Connected to millstone 6.

[0024] The top of the base 1 is also provided with a support rod 10, the support rod 10 is parallel to the grindstone 6, the upper end of the support rod 10 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com