Construction Method of Comprehensive Frequency Response Function Equation of Large Pitch Screw Turning Technology System

A technology of frequency response function and process system, which is applied in the construction of comprehensive frequency response function equation of large-pitch screw turning process system and the construction of comprehensive frequency response function of cutting system, which can solve the problem of affecting the service life of the tool system, complex vibration characteristics, and inability to reflect the process. System Dynamics Behavior etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

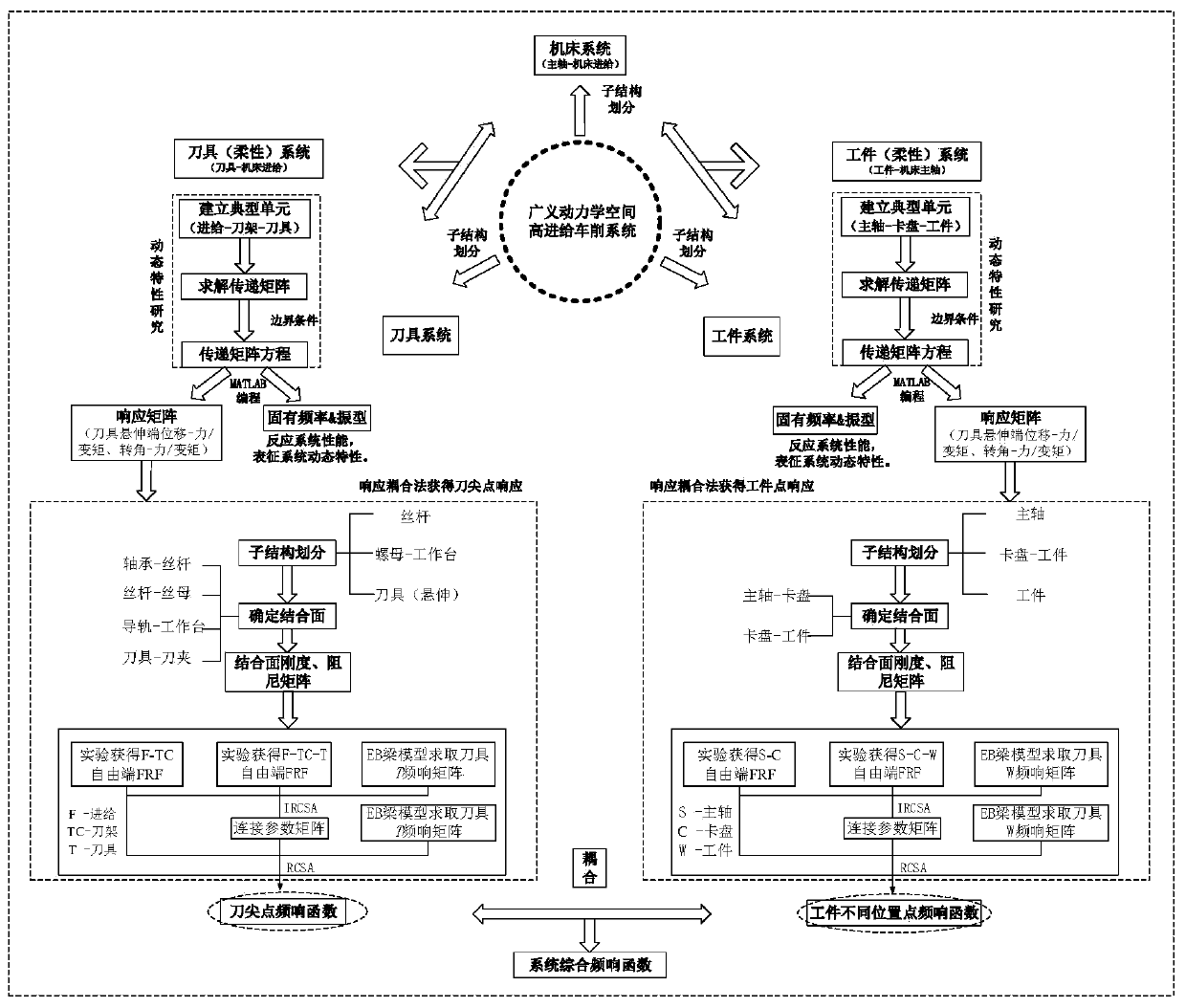

[0079] See Figure 1-5 , the present invention is based on the generalized dynamic space large-pitch screw turning system comprehensive frequency response function construction method, specifically comprising the following steps:

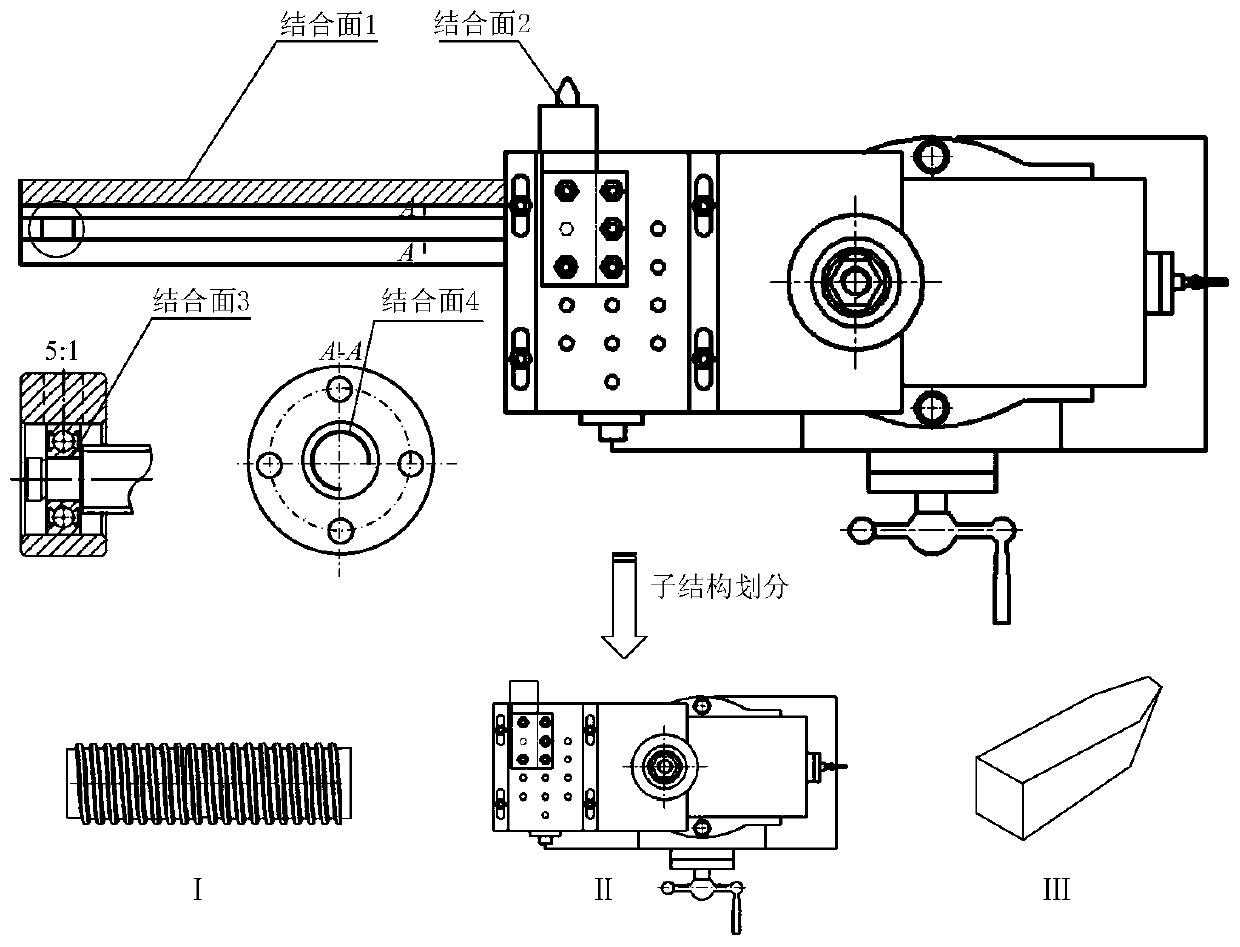

[0080] Step 1. Construct the tool-machine tool feed system subsystem frequency response function model

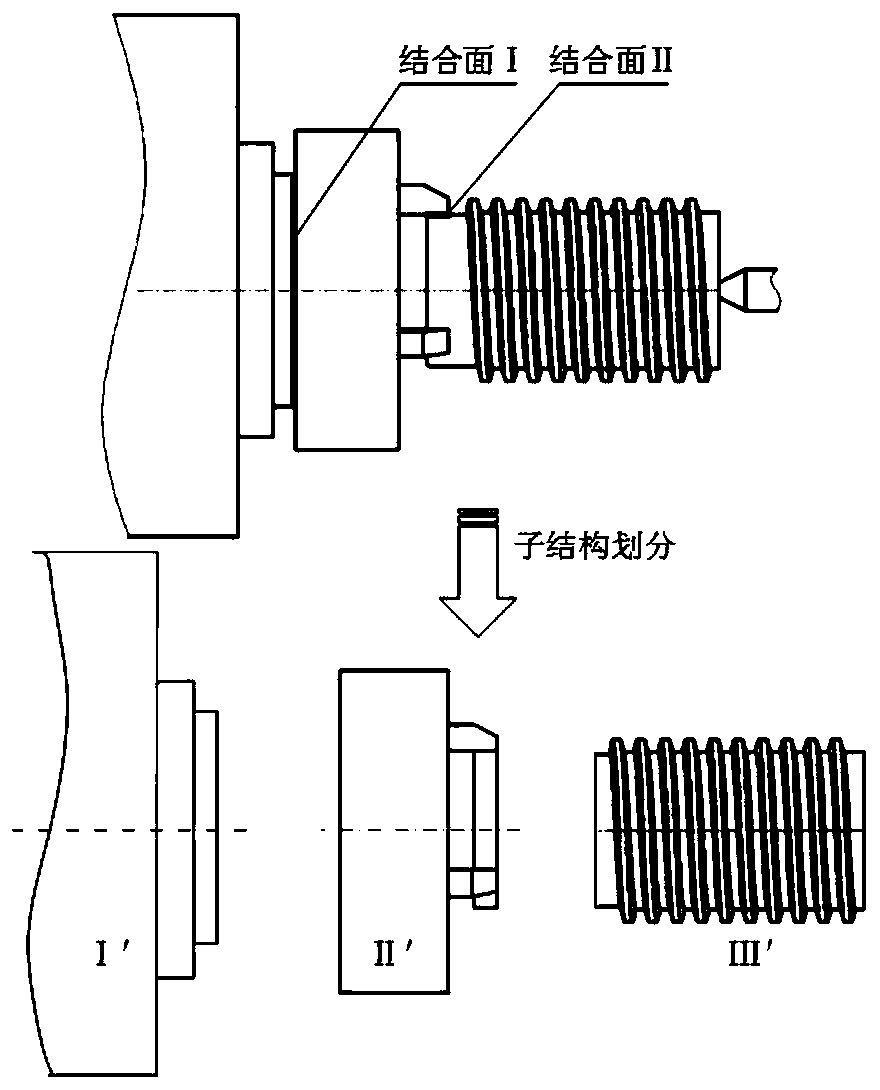

[0081] First, the tool-machine tool feed system subsystem is simplified into screw, nut, guide rail, workbench, tool holder-part tool and tool overhang; based on the theory of response coupling method, the tool-machine tool feed system subsystem It is divided into three substructures: Ⅰ (screw), Ⅱ (nut-table-tool holder-part of the tool) and Ⅲ (tool overhang part), and consider the following four combinations o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com