Anti-explosion valve for lithium ion battery

A technology of lithium-ion batteries and explosion-proof valves, which is applied to battery pack parts, circuits, electrical components, etc., can solve the problems of slow blasting and exhaust speed, and achieve the effects of high safety performance, small stress, and fast pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

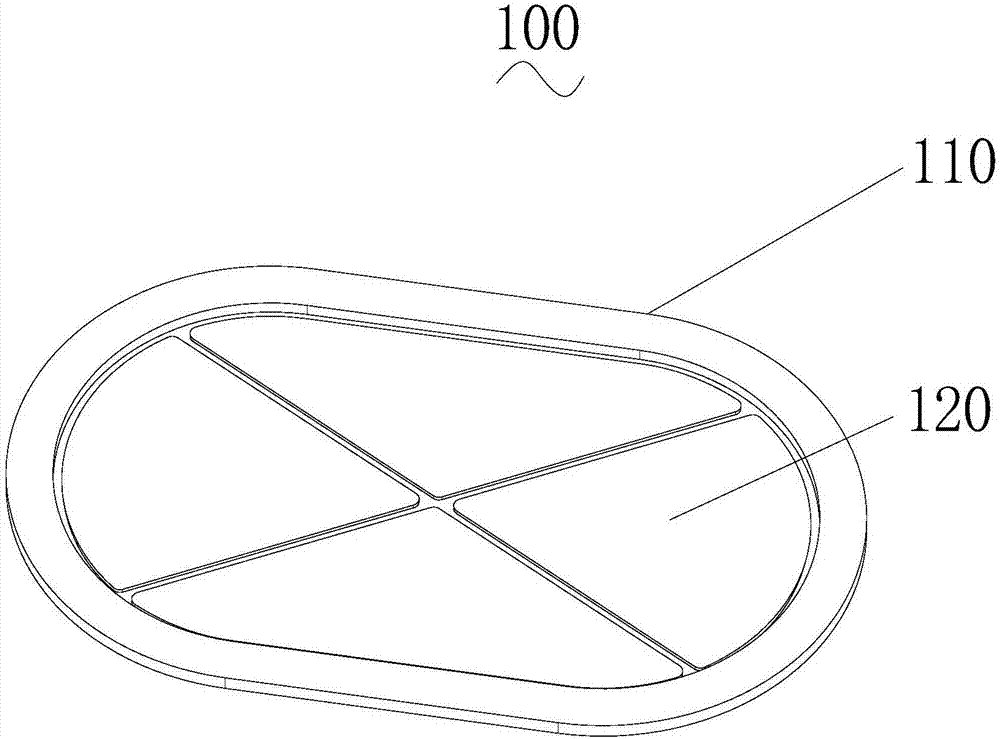

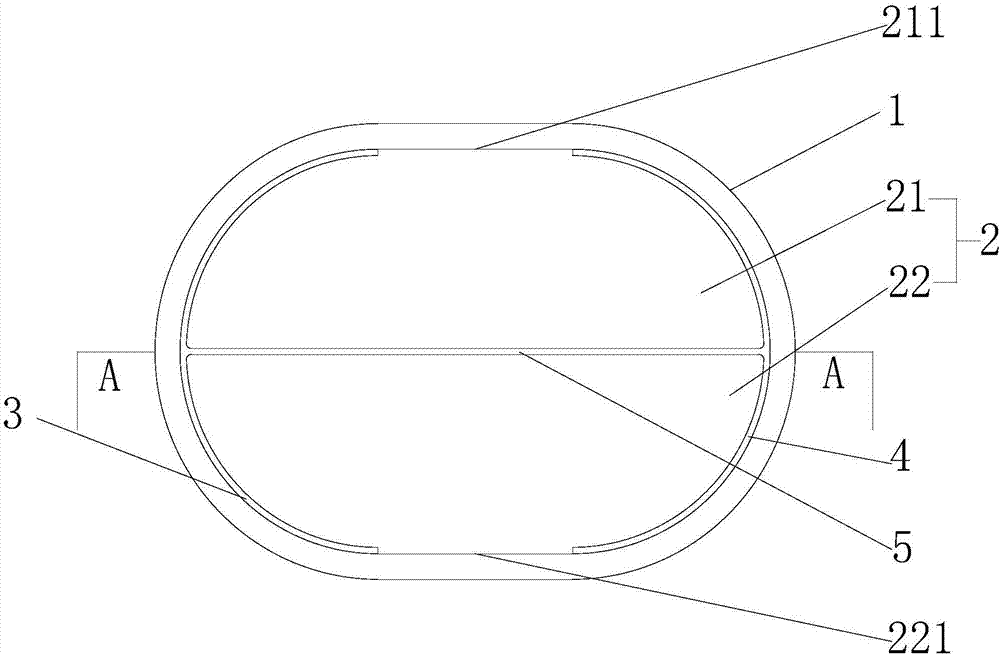

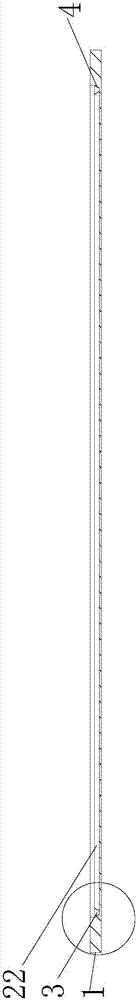

[0022] see Figure 2-4 , an explosion-proof valve for lithium-ion batteries, comprising an explosion-proof substrate 1 and an explosion-proof sheet 2, the explosion-proof sheet 2 is arranged in the explosion-proof substrate 1, the explosion-proof sheet 2 includes an explosion-proof sheet 1 21 and an explosion-proof sheet 2 22, and the explosion-proof sheet 1 21 The edge two 221 of the edge one 211 and the explosion-proof disc two 22 are connected with the explosion-proof substrate 1 respectively, and the inner wall of the explosion-proof substrate 1 is provided with a blasting line one 3 and a blasting line two 4, and the two ends of the blasting line one 3 are connected with the blasting line two respectively. 4 There is a space between the two ends, and the blasting line 3 5 is arranged between the blasting line 1 3 and the blasting line 2 4; the two opposite side edges of the explosion-proof disk 1 21 and the two opposite side edges of the explosion-proof disk 2 22 are respe...

Embodiment 2

[0027] see Figure 5 , The difference between this embodiment and Embodiment 1 lies in the shapes of blasting line 1 3 and blasting line 2 4. In this embodiment, blasting line 1 3 and blasting line 2 4 are C-shaped arc structures.

Embodiment 3

[0029] The difference between this embodiment and Embodiment 1 is that the thickness of the explosion-proof substrate 1 is 0.5 mm. The thickness of the explosion-proof disc 2 is 0.2 mm, and the thickness of the blasting line 1 3 , the blasting line 2 4 and the blasting line 3 5 are all 0.06 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com