Bottom plate for thin plate dense resin plugging and making method thereof

A resin plug hole and bottom plate technology, which is used in the manufacture of printed circuits, the formation of electrical connection of printed components, and electrical components, can solve the problems of easy bending of circuit boards, poor quality of plug holes, and large hollow area to ensure flatness. , the effect of reducing the quantity and reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

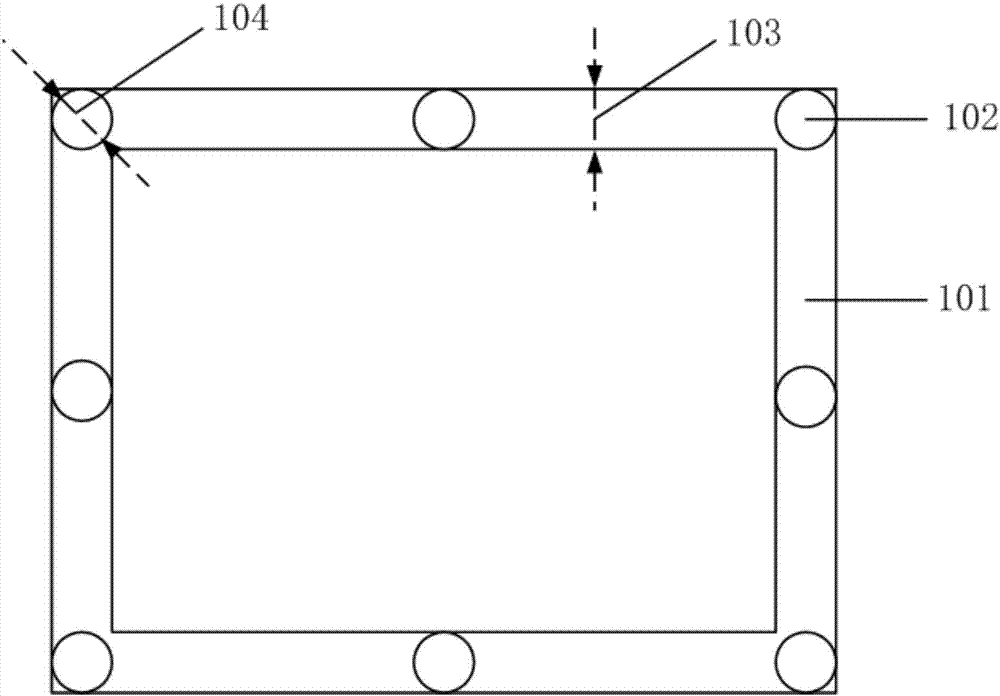

[0031] see figure 2 , figure 2 It is a structural schematic diagram of the bottom plate used for dense resin plug holes in thin plates in this embodiment. As shown in the figure, a bottom plate for thin plate dense resin plug holes includes an unhollowed air guide groove 101, the air guide groove 101 corresponds to the thin plate dense resin plug hole pattern, and hollowed out air guide holes are appropriately added in the air guide groove 101 102.

[0032] The shape of the air guide groove 101 is a closed rectangle, and the air guide holes 102 are drilled at the four corners of the closed rectangular air guide groove 01 and the center points of the four sides of the rectangle, and there is a certain distance between adjacent air guide holes, so that The bottom plate still has sufficient supporting force and is not easily deformed, so that the circuit board on it is not deformed during the plugging process, has high flatness, and improves the quality of the plugging hole. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com