A zipper with self-locking function

A functional and zipper technology, applied in the field of zippers, can solve problems such as disengagement, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail through the accompanying drawings and specific embodiments below.

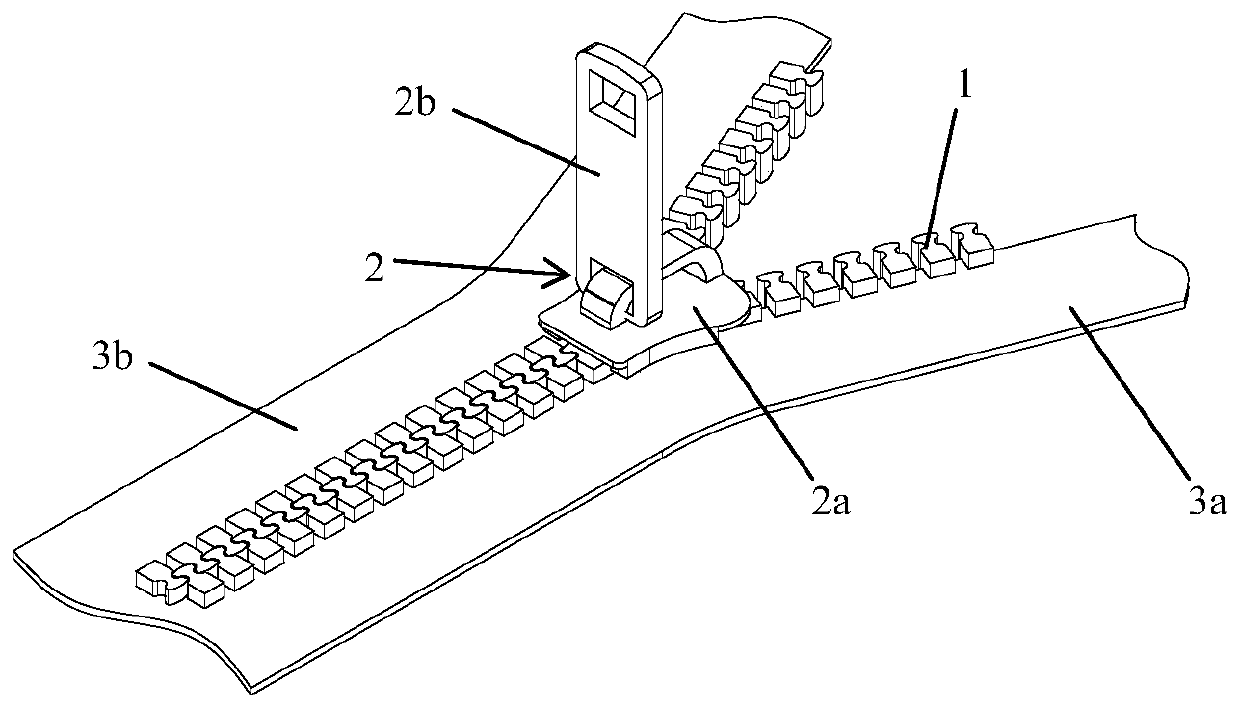

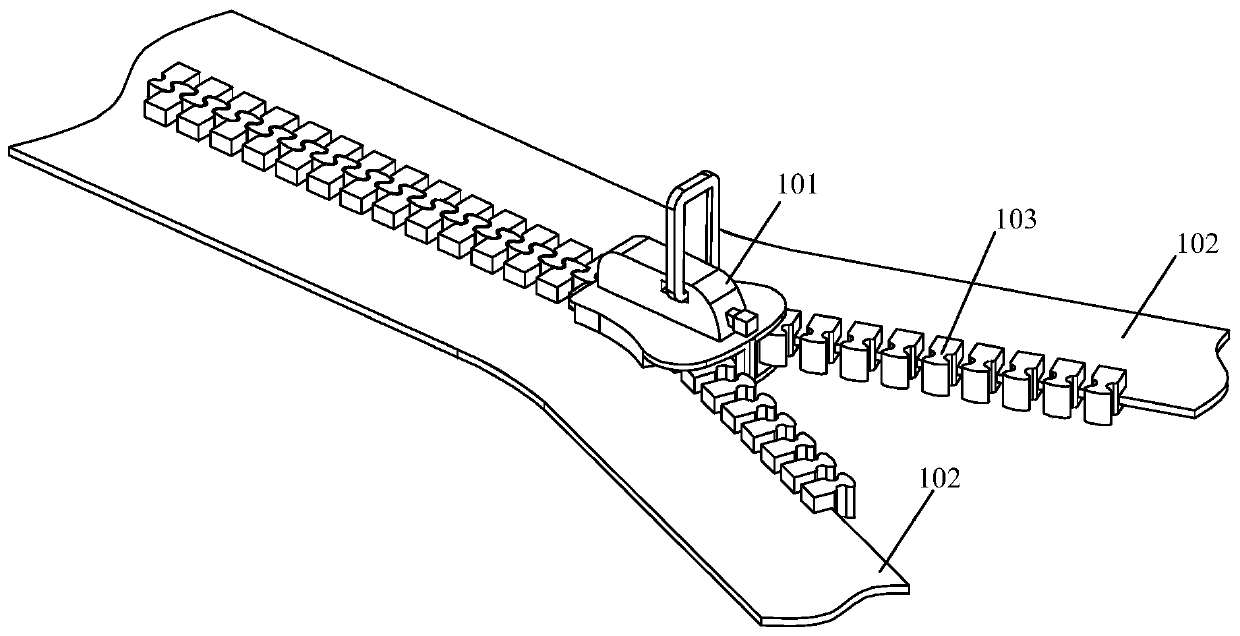

[0014] Such as figure 2 As shown, the present embodiment provides a zipper with a self-locking function, including a slider 101 , two chain straps 102 and several fastener elements 103 disposed on the chain straps 102 .

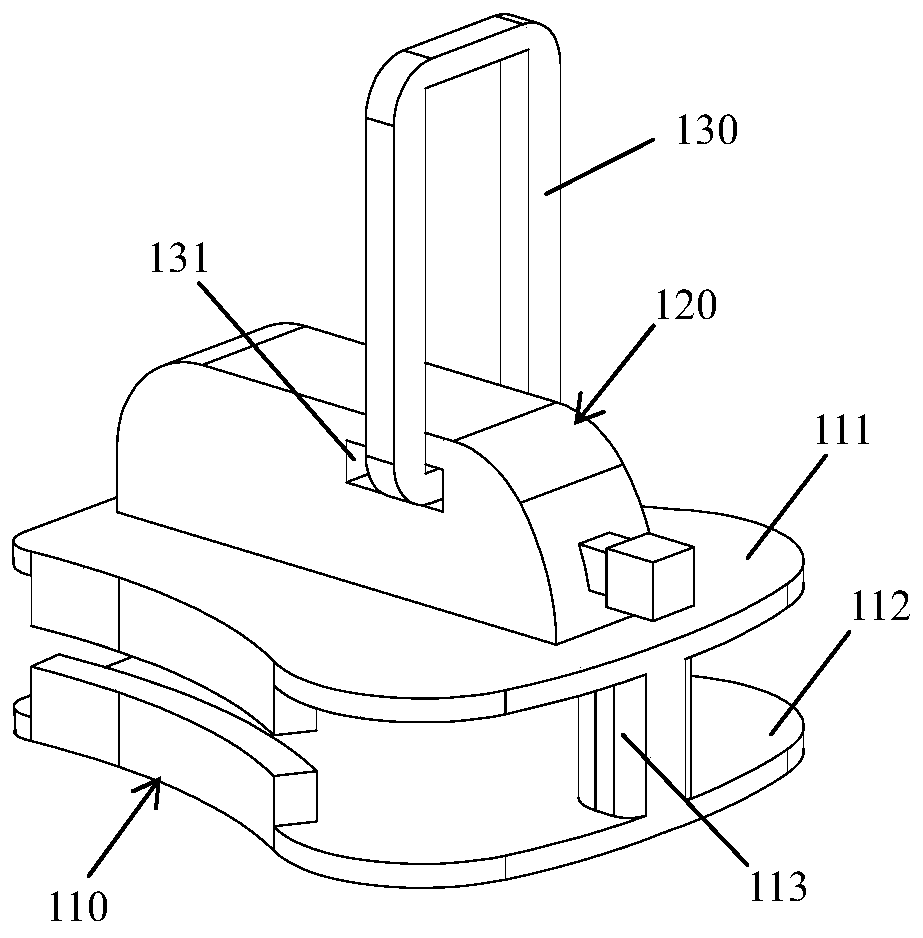

[0015] Such as image 3 As shown, the slider 101 includes a splint part 110 of plastic material for clamping the chain belt 102 therein, a locking part 120 on the splint part 110 and a plastic material on the locking part 120 The splint portion 110 includes an upper splint 111 and a lower splint 112 arranged in parallel and a column 113 connecting the upper splint 111 and the lower splint 112 , and the column 113 is located on the front side of the splint portion 110 . In the present invention, the so-called front side refers to the direction in which the slider 101 is pulled to engage the fastener elements 103 , and the so-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com