Automatic film covering type shoe cover machine

A technology of shoe cover machine and film coating, which is applied in the direction of clothing, applications, hangers, etc., can solve the problems of complex production process, waste of materials, high production cost of shoe covers, etc., and achieve the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

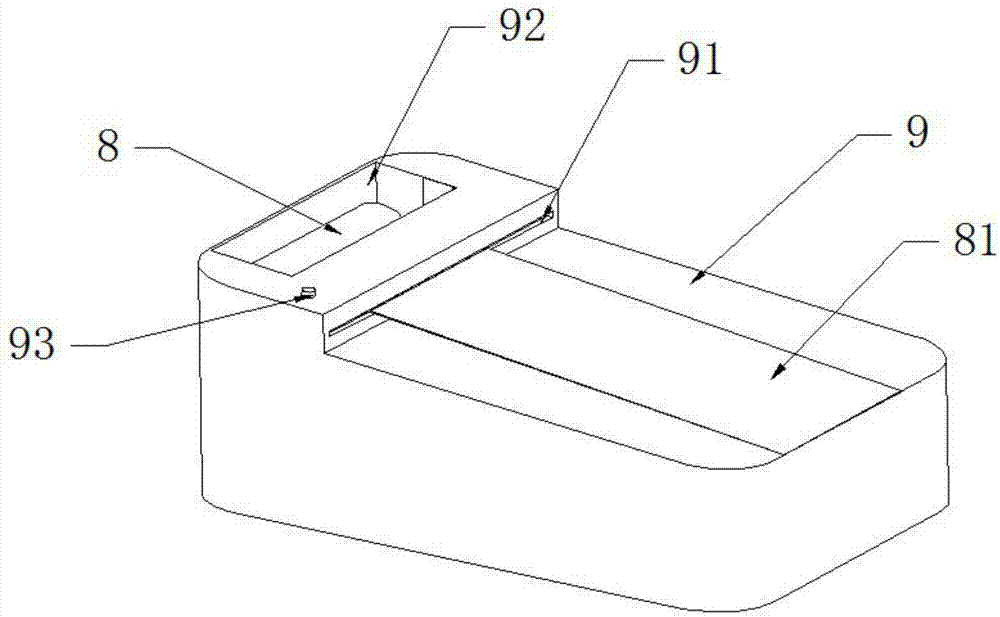

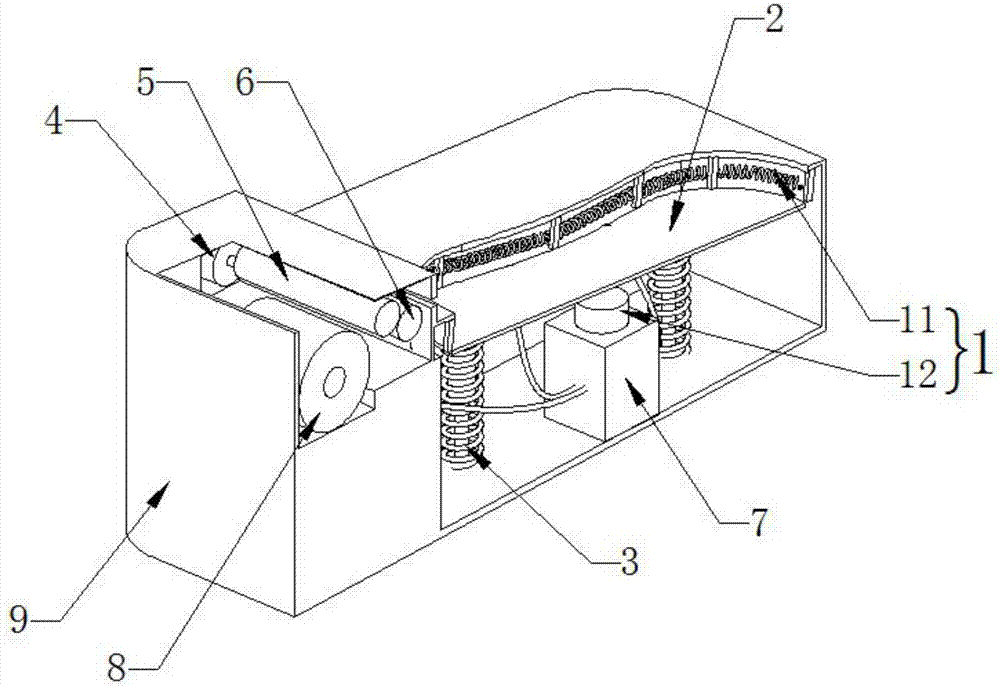

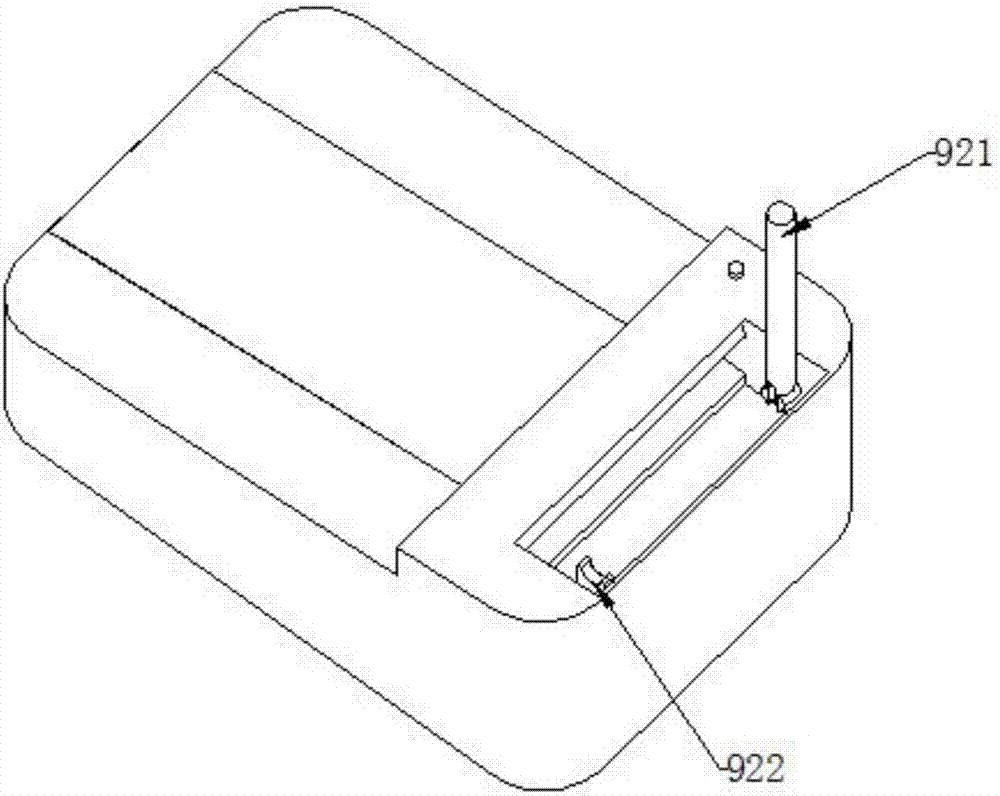

[0020] An automatic film-coated shoe cover machine, including a far-infrared heating device 1, a pedal 2, a spring return device 3, a motor 4, a driving roller 5, a driven roller 6, a control device 7, a roll-type heat shrinkable film 8 and Shell 9; the top of the pedal 2 is covered with a heat-shrinkable film 81, the spring return device 3 is arranged below the pedal 2, the far-infrared heating device 1 includes a heating resistance wire 11, a heating device switch 12, and the heating The resistance wire 11 surrounds the pedal 2, and the heating device switch 12 is arranged under the pedal 2; the control device 7 is connected with the heating device switch 12 and the motor 4, and the casing 9 is provided with a film outlet 91.

[0021] The overall effect of the present invention is: when the pedal 2 is stepped on, the far-infrared heating device 1 will be in a energized state, so that the heating resistance wire 11 will generate heat, and then the heat shrinkable film 81 will ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com