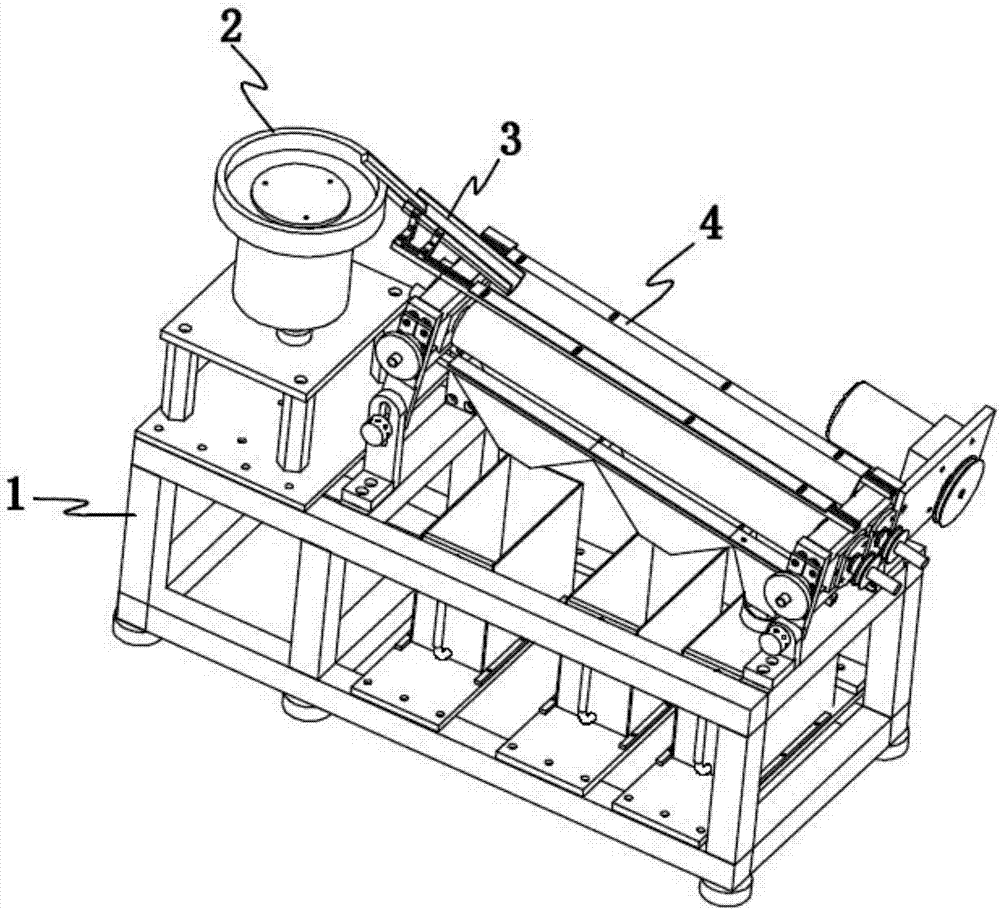

Water chestnut sorting machine

A technology of sorting machines and water chestnuts, applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of poor popularization and use, high manufacturing cost of sorting equipment, low efficiency of agricultural products, etc., and achieve equipment adjustment and Easy to use, low manufacturing cost, guaranteed quality and price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] When this sorting equipment sorts water chestnuts, the driving motor 403 of the sorting mechanism 4 will be started, and the driving motor 403 will drive the first roller 414 and the second roller 415 to rotate through the belt transmission mechanism of the driving wheel 404 and the driving wheel 405, Then put the water chestnuts to be sorted into the vibrating output tray 2, and the water chestnuts, driven by the rotation and vibration of the vibrating output tray 2, are discharged into the feeding trough plate 3 from the discharge port one by one, and enter the feeding chute plate 3 from the feeding chute. The feeding opening plate 409 on the top of the blanking gap between the first roller 414 and the second roller 415, the water chestnuts roll down along the feeding opening plate 409, and the water chestnuts roll down along the feeding opening plate 409 During the rolling process, the water chestnuts drop from the first roller 414 and the second roller 415 to the fir...

Embodiment 2

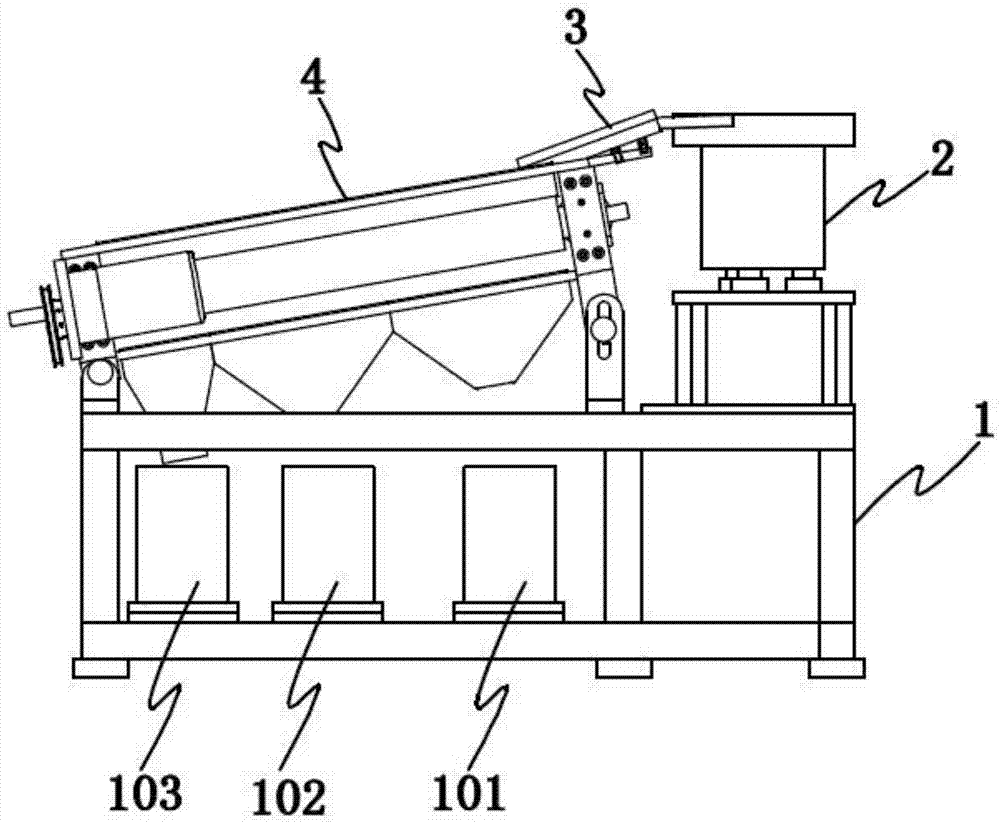

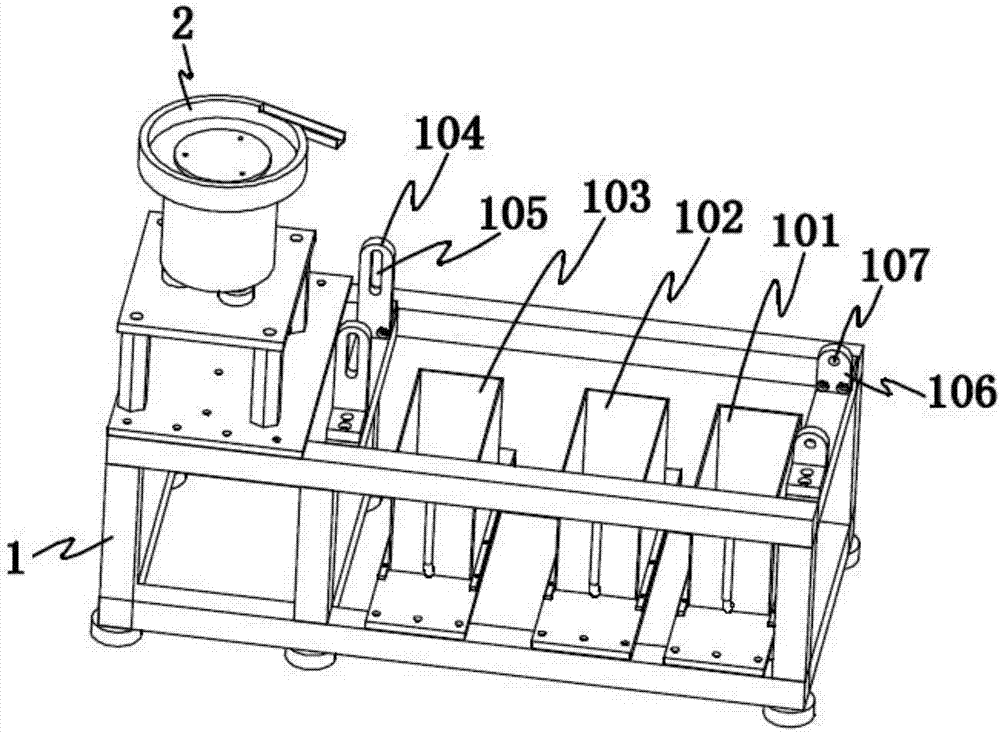

[0032]The sorting mechanism 4 of this sorting equipment is connected to the upper end surface of the frame body 1 through the connection hole 413 on the mechanism base I401 and the mechanism base II402, and the frame body 1 is connected to the connection hole 413 through the long slot hole 105 of the upper end surface mounting ear I104 Knob connection, through the connection ear hole 107 of the upper end mounting ear II 106 and the connection hole 413 knob, through manual adjustment of the knob, the mechanism base I401 moves up and down along the long slot hole 105, and the mechanism base II402 rotates around the connection hole 413, thereby adjusting the sorting The pitch angle between the mechanism 4 and the upper end surface of the frame body 1 changes the rate at which water chestnuts roll down along the feeding opening plate 409 of the sorting mechanism 4, and the first roller 414 of the sorting mechanism 4 at the two shaft ends simultaneously The part is movably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com