Metal sheet cleaning stirring device

A stirring device and hardware sheet technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as easy hitting of hardware parts, affecting cleaning effect, and reducing the service life of stirring paddles. To achieve the effect of increasing service life and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

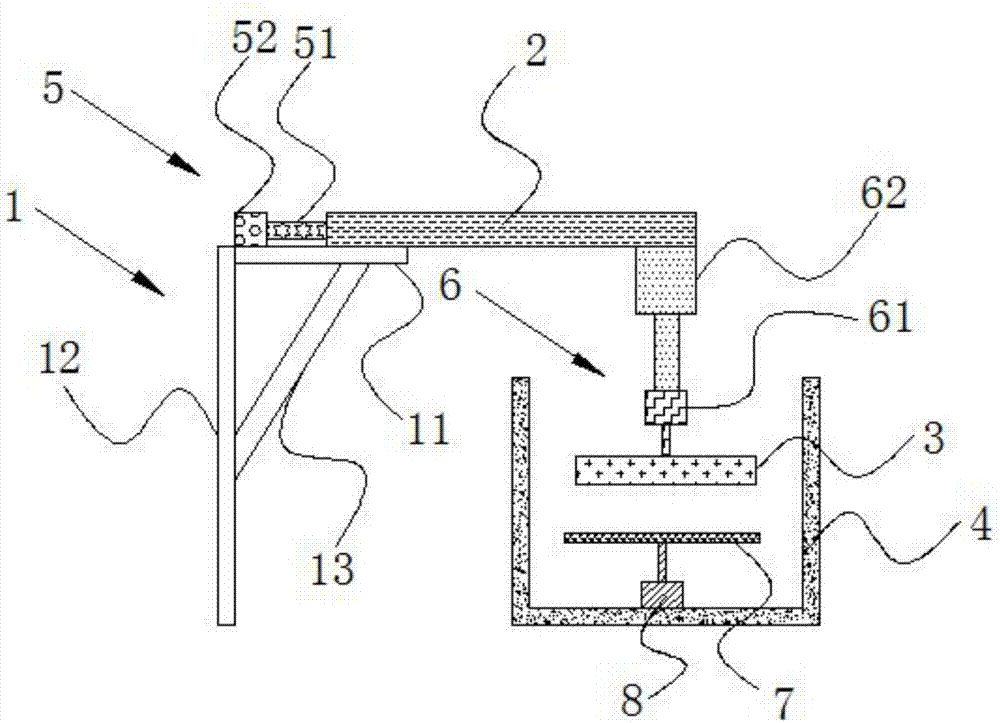

[0018] Embodiment: a kind of hardware sheet cleaning stirring device, as figure 1 As shown, it includes a bracket 1, a slide bar 2, a vacuum suction cup 3 and a cleaning tank 4, the slide bar 2 is fixed on the bracket 1, the vacuum suction cup 3 is located under the slide bar 2, and the cleaning tank 4 is provided with There is a cleaning solution, the cleaning tank 4 is located below the vacuum chuck 3, the slide bar 2 is provided with a moving drive mechanism 5 that drives the slide bar 2 to move horizontally, and a driving mechanism 5 is provided above the vacuum chuck 3. The rotary lifting mechanism 6 for the rotation and lifting of the vacuum chuck 3;

[0019] The moving drive mechanism 5 includes a screw rod 51 and a moving driving motor 52 that drives the slide bar 2 to move horizontally. The moving driving motor 52 is fixed on the support 1, and one end of the screw rod 51 is connected to the moving The output shaft of the driving motor 52 is connected, and the other ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap