Working method of high-efficiency terminal assembling mechanism for manufacturing automobile lamp holder

A technology for automotive lamp holders and assembly mechanisms, which is applied in the direction of manufacturing tools, assembly machines, and metal processing equipment. The effect of pass rate, improvement of product quality and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

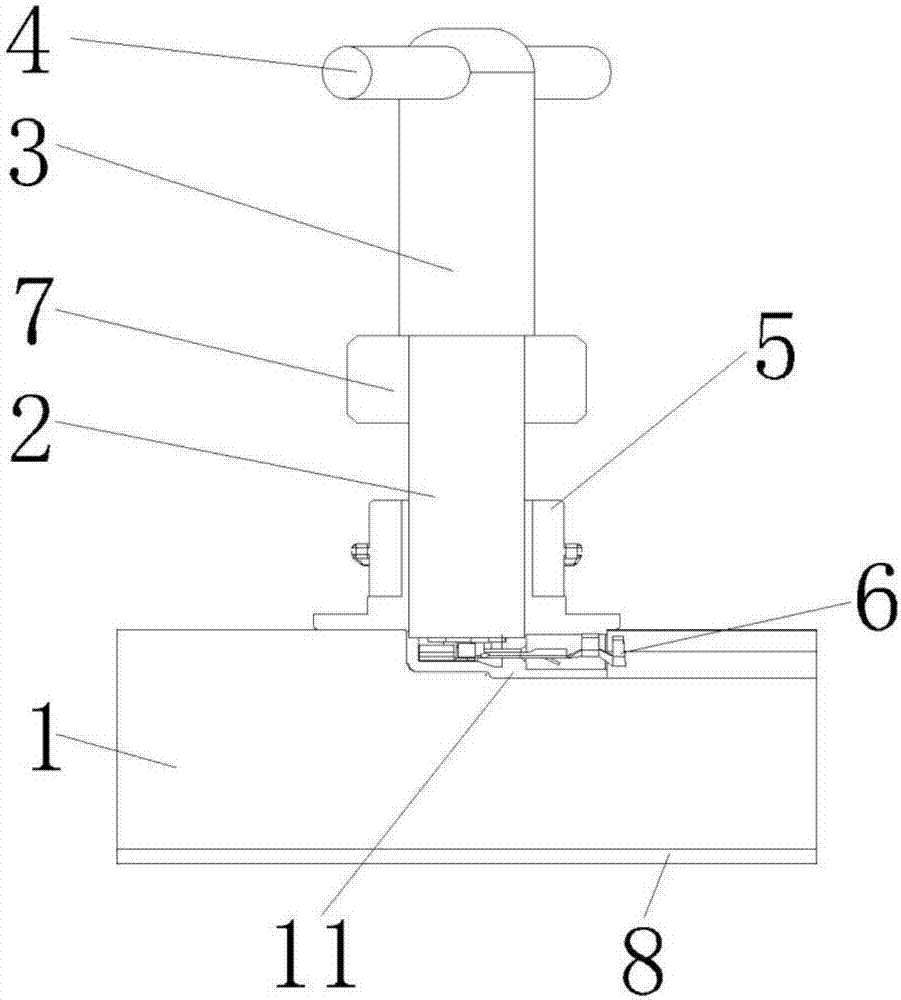

[0024] Such as figure 1 As shown, the working method of a high-efficiency terminal assembly mechanism for automobile lamp holder manufacturing in this embodiment, the specific working steps are as follows:

[0025] (1) Fix the lamp holder 5 and the terminal 6 in the slot 11 of the fixing seat 1;

[0026] (2) Put the first rotating rod 2 and the second rotating rod 3 with the fixed chute 7 and the handle 4 into the hole of the lamp holder 5, and connect them with the terminal 6;

[0027] (3) Slide the handle 4 forward according to the guide of the fixed chute 7, and under the action of the rotating force, the terminal 6 is pushed into the interior of the lamp holder 5 until the terminal 6 is assembled in place;

[0028] (4) After the assembly is completed, the worker directly takes out the lamp holder 5 equipped with the terminal 6 from the fixing seat 1 .

[0029] In the working method of this embodiment, the staff operates according to the guide arrows provided on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com