Intelligent warehousing sorting station and sorting method thereof

A technology of intelligent warehousing and packaging, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problems that cannot meet the standards of modern enterprise industrialization, efficiency, accuracy, labor costs, and warehouse management can not keep up with the quality of life High demand and other issues, to achieve the effect of improving warehouse management and sorting efficiency, low manpower requirements, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

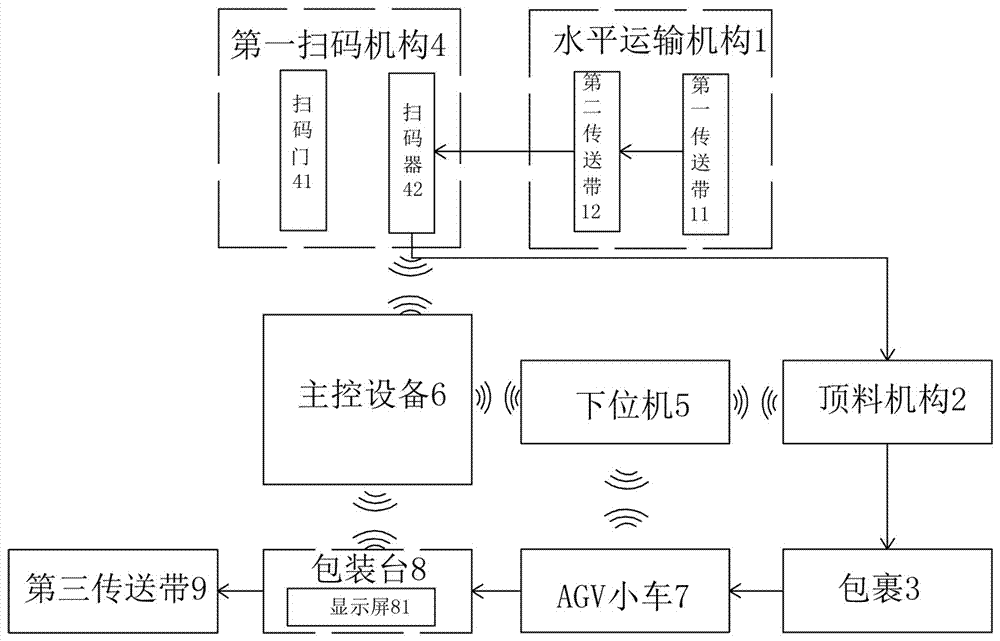

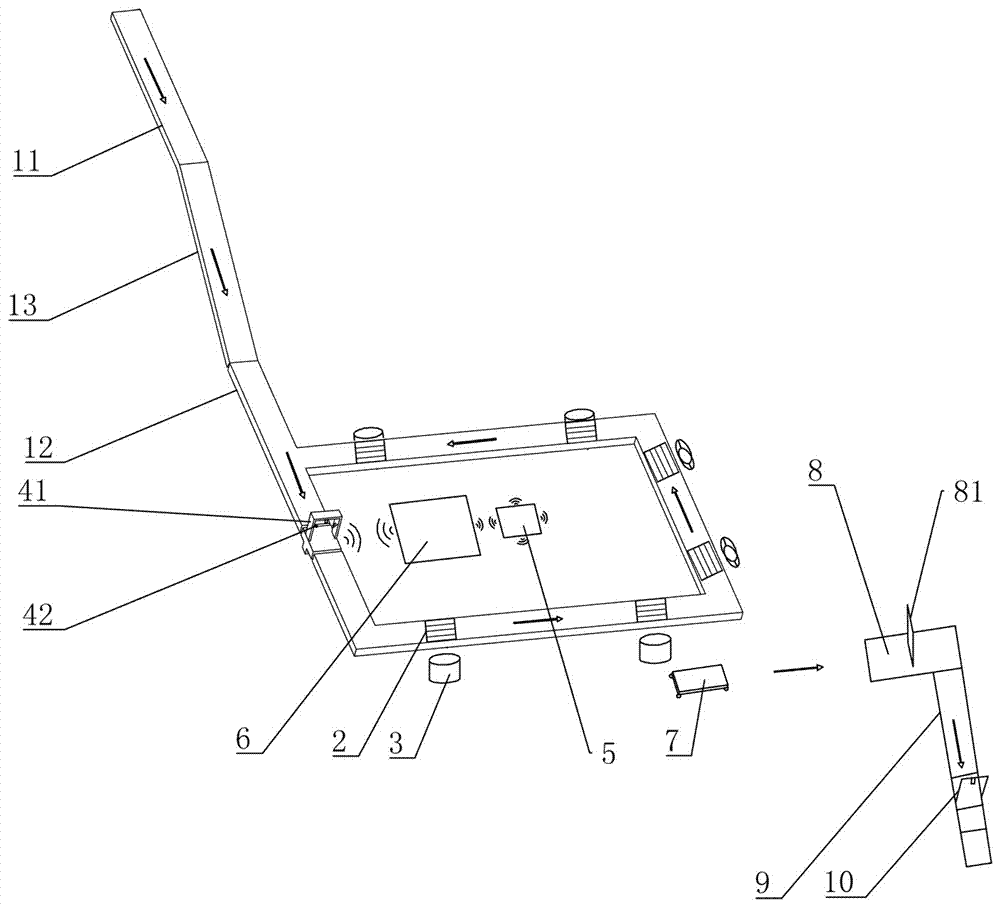

[0030] refer to Figure 1 to Figure 2 The embodiment of an intelligent warehouse sorting station of the present invention will be further described.

[0031] Such as figure 1 and figure 2As shown, this intelligent warehouse sorting station includes a horizontal transport mechanism 1, a material ejection mechanism 2, a first code scanning mechanism 4, a lower computer 5, a main control device 6, an AGV trolley 7 and a packaging platform 8, wherein the main control device 6 is connected with the lower computer 5 and the first code scanning mechanism 4 through wireless communication, and the main control device 6 as the upper computer can issue control commands to the lower computer 5, and the lower computer 5 is used to directly control the ejecting mechanism 2 and the AGV trolley 7. In the actual sorting process, when the order is accepted, the main control device 6 will set all the items on the order as a package 3 task, and each item in the package 3 corresponds to a small...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com