In-warehouse logistics sorting method and system

A sorting system and logistics technology, applied in sorting and other directions, can solve the problems of goods delivery errors, manual removal, etc., and achieve the effect of reducing difficulty, reducing manpower requirements, and reducing error rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with accompanying drawing.

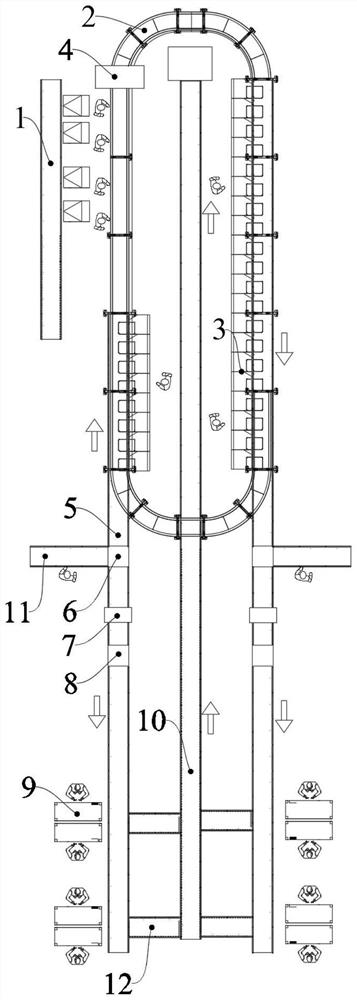

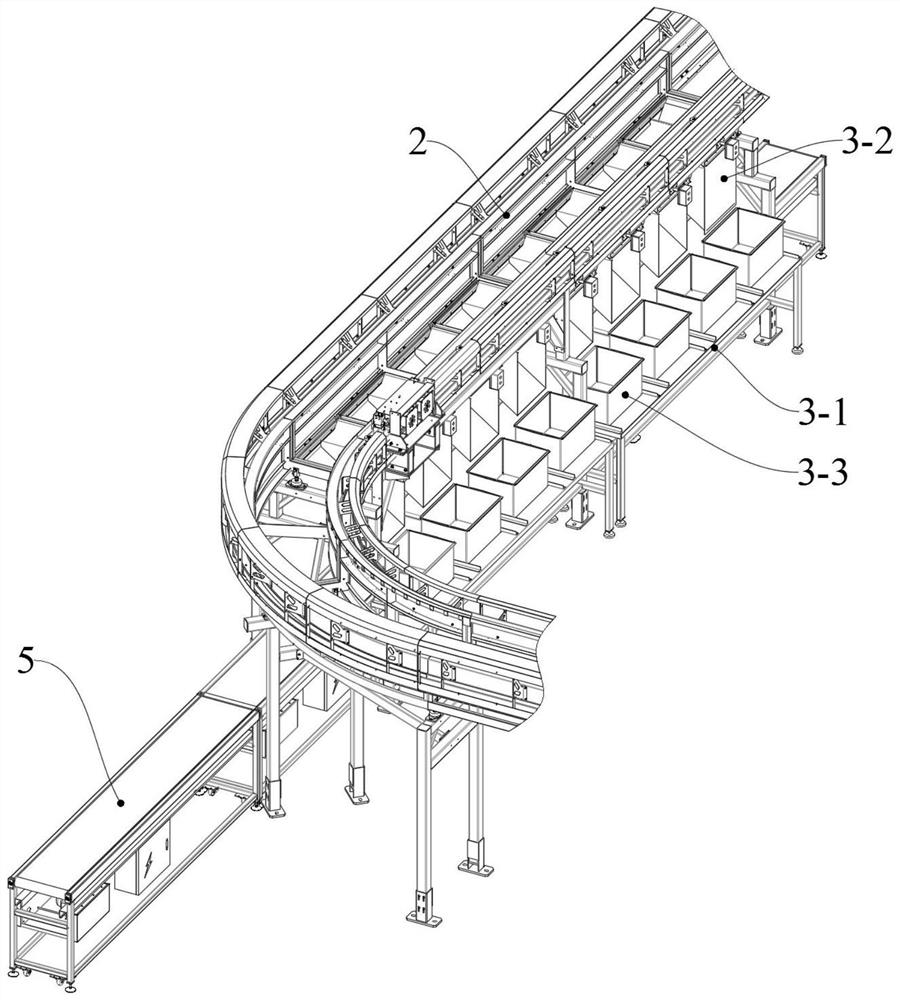

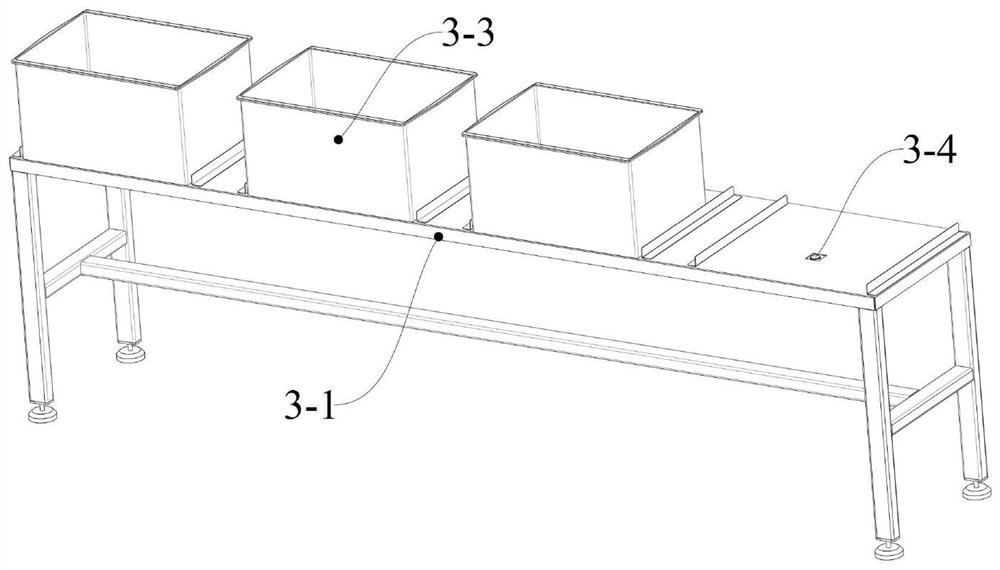

[0039] Such as figure 1 As shown, an in-warehouse logistics sorting system includes a loading line 1, a sorting machine 2, an unpacking platform 3, a transfer review module, and a host computer. Sorting machine 2 specifically adopts a flap type ring sorting machine, and its sorting trolley sends the goods into the lower bag slot by turning down the tray. The two straight sections of the sorter 2 are provided with an upper bag section and a lower bag section. The upper bag section is only arranged on one of the straight line parts. The two sections of straight lines are provided with underpack sections. The feeding line 1 is arranged in parallel on the side of the bagging section of the sorter 2 . There is a bagging operation space between the feeding line 1 and the bagging section of the sorter 2, which is convenient for the staff to put the goods on the feeding line 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com