Washer electric device mounting structure and washer with same

An installation structure, washing machine technology, applied to other washing machines, washing devices, household appliances, etc., can solve the hidden dangers of the overall disassembly of the washing machine, the inability to install electrical components, and the difficulty of disassembly, etc., to achieve small overall changes and prevent electrical components. The effect of loosening and tightening the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

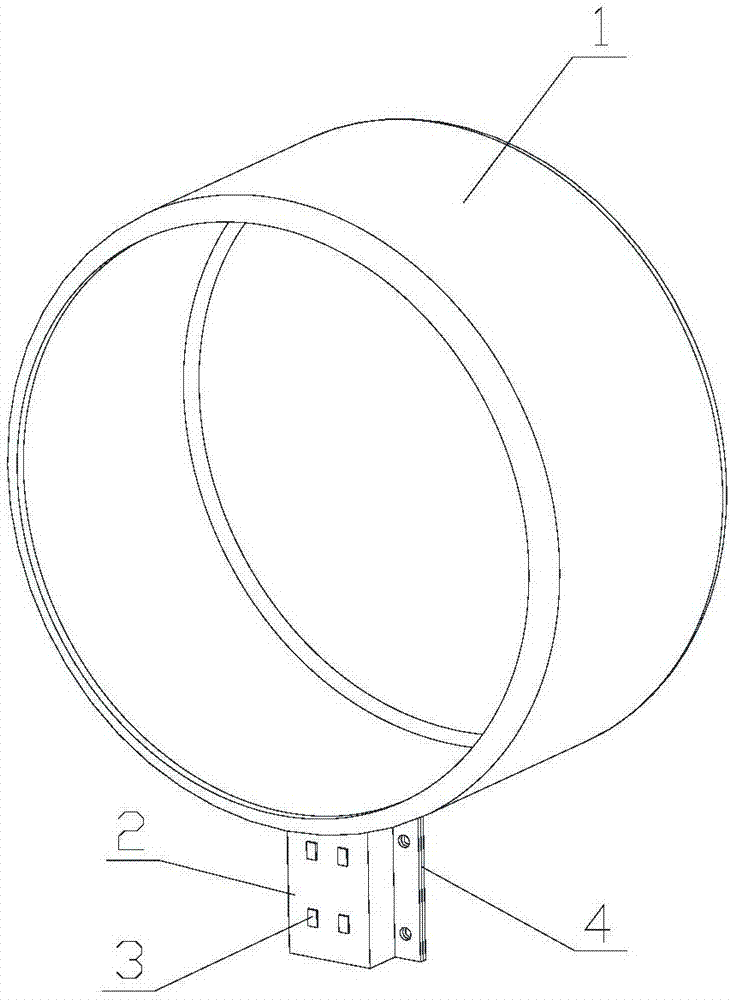

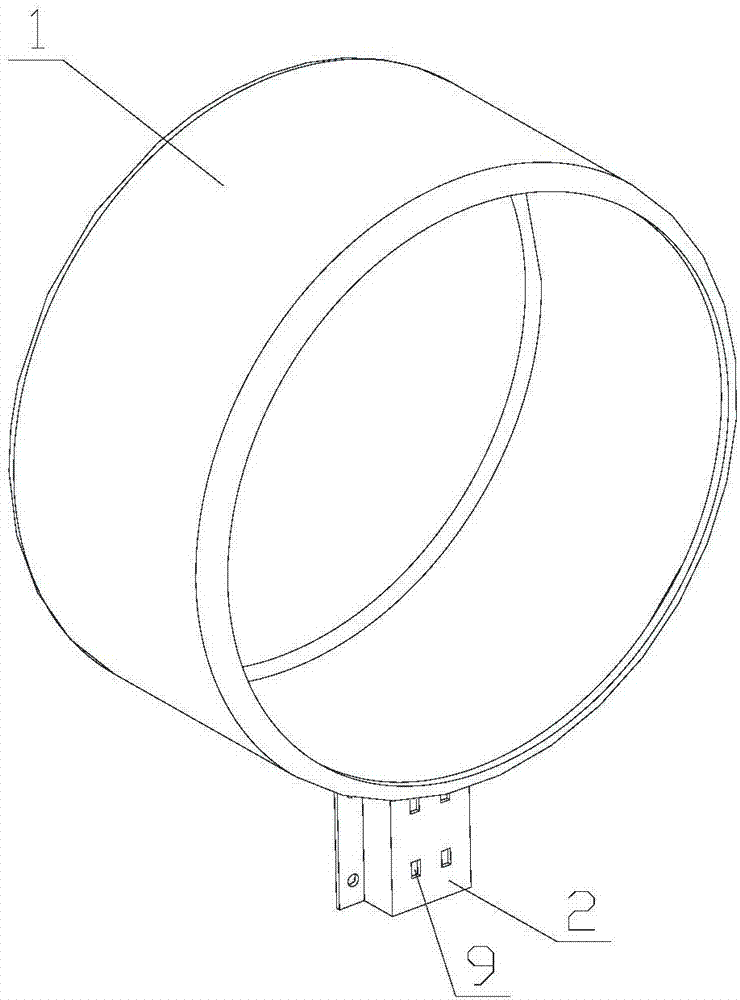

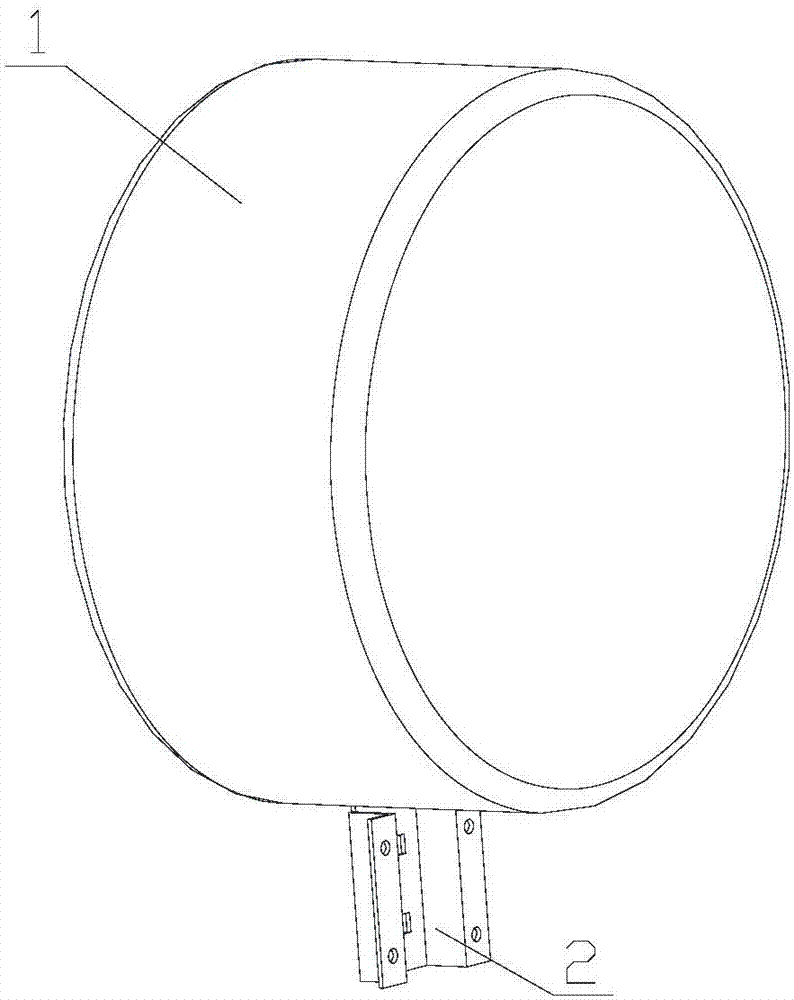

[0043] Such as Figure 1 to Figure 6 As shown, the installation structure of a washing machine electrical device 3 described in this embodiment is characterized in that it includes the washing machine outer cylinder 1 installed on the support body, and the first installation unit 2 arranged on the wall of the washing machine outer cylinder 1; The first installation unit 2 is detachably connected to the electrical device 3, and the electrical device 3 is a capacitor; the first installation unit 2 is arranged at the bottom of the wall of the washing machine outer cylinder 1, and is a groove structure matched with the electrical device 3 5. The first installation unit 2 includes a first bending surface 6, a second bending surface 7 connected to and bent from the first bending surface 6, connected to the second bending surface 7 and bent towards the first The third bending surface 8 is bent on one side of the surface 6 , and the three bending surfaces form the groove structure 5 ....

Embodiment 2

[0047] Such as Figure 1 to Figure 6 As shown, this embodiment is a further limitation of the first embodiment described above. The material used in the installation structure of the washing machine electrical device 3 described in this embodiment is a metal material, wherein the first installation unit 2 is formed by sheet metal bending at one time. The first installation unit 2 and the cylinder wall of the outer cylinder 1 of the washing machine are formed by welding.

Embodiment 3

[0049] Such as Figure 1 to Figure 6 As shown, the difference between this embodiment and the above-mentioned second embodiment is that the first installation unit 2 and the second installation unit 4 described in this embodiment are formed by a mold at one time, rather than cold-worked sheet metal bending.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap