Ice storage tank structure that can enhance the efficiency of internal ice melting

An ice storage tank and high-efficiency technology, which is applied in ice storage/distribution, ice manufacturing, household heating, etc., can solve the problems of large space required, hindered ice melting and cooling rate, high ice storage rate, etc., and achieve ice melting efficiency High, the effect of exerting the energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Cooperate with the explanation of illustration, figure number below hereby, introduce its specific embodiment of the present invention in detail after:

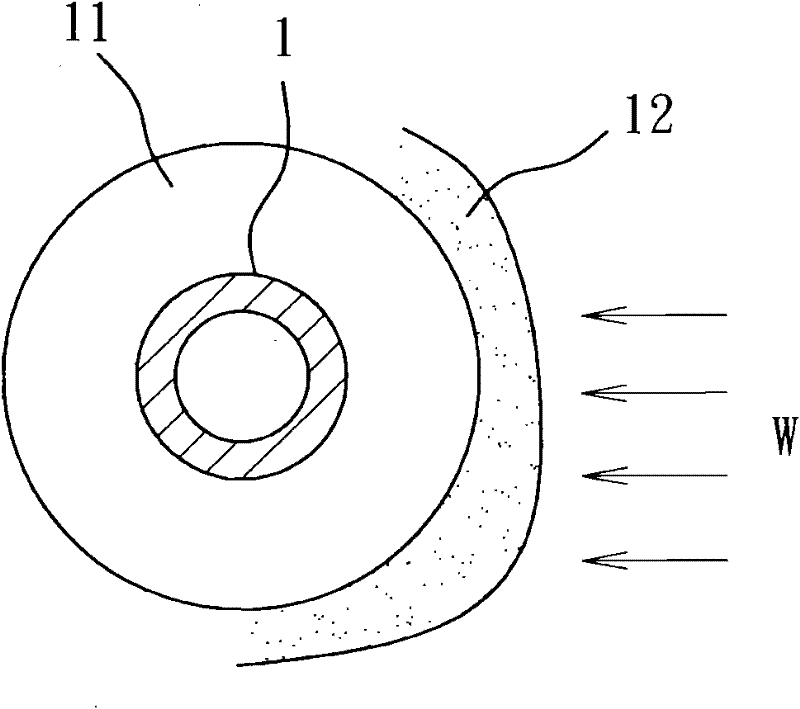

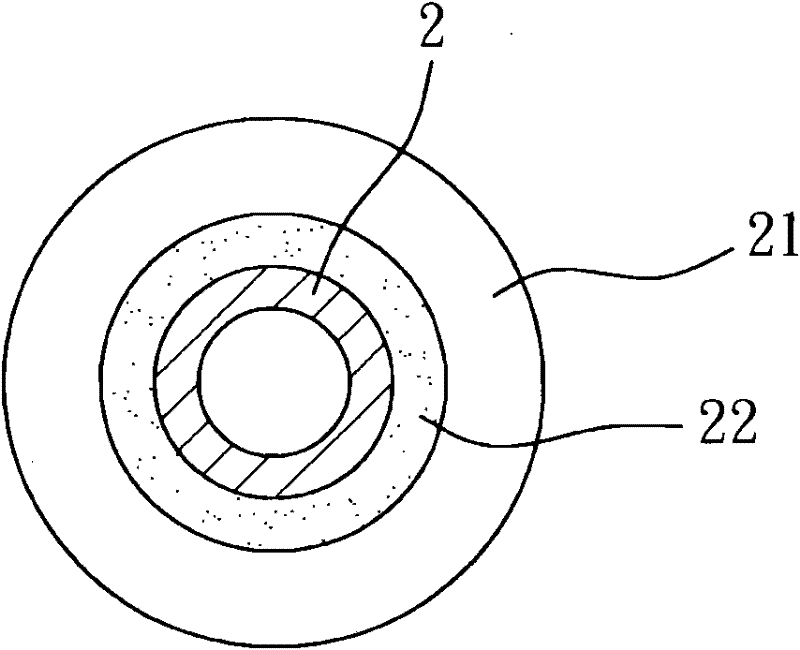

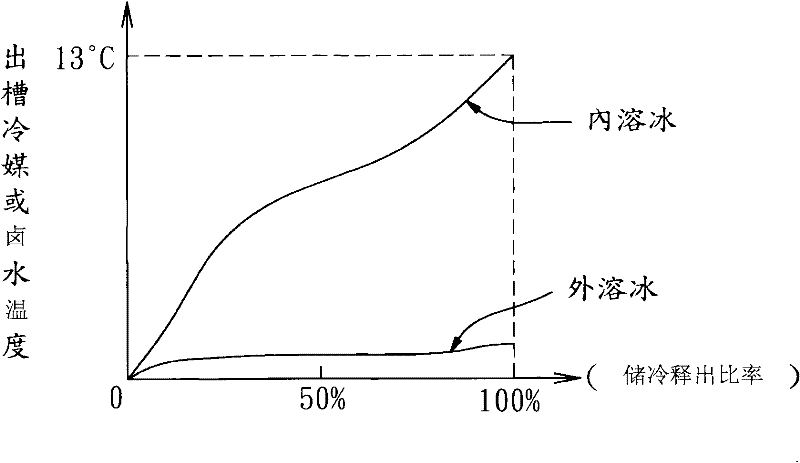

[0021] See first Figure 4 As shown, the ice storage cycle schematic diagram of the ice storage air-conditioning system of the present invention, that is, during the ice storage cycle, the ice-making / air-conditioning main unit 3 is used to send the operating heat from a cooling pump 74 to a cooling water tower 6 for discharge, and a main unit pump 73 Then send the brine to the ice making / air conditioner main unit 3 to cool down to -5°C, and transfer it to an ice storage tank 4 by an ice storage pump 71 for ice storage circulation, and store cold in the ice storage tank 4; During the ice melting cycle (such as Figure 5 shown), the ice storage tank 4 starts to melt ice and release cooling, and a heat exchange pump 72 is used to transfer the brine to a heat exchanger 5, so as to provide air conditioning to the air-condi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com