Bridge deck pavement structure

A bridge deck pavement and bonding layer technology, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of main girder damage, noise pollution, water pollution, etc., to avoid noise pollution and water pollution, save time and money resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solution and advantages of the present invention clearer, detailed description will be given below in conjunction with the accompanying drawings.

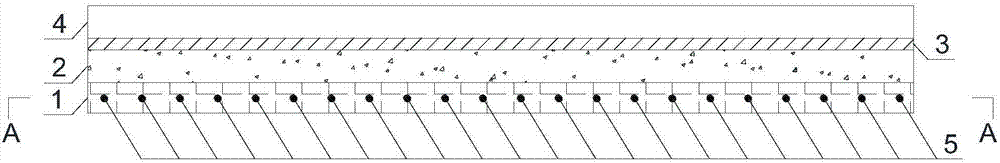

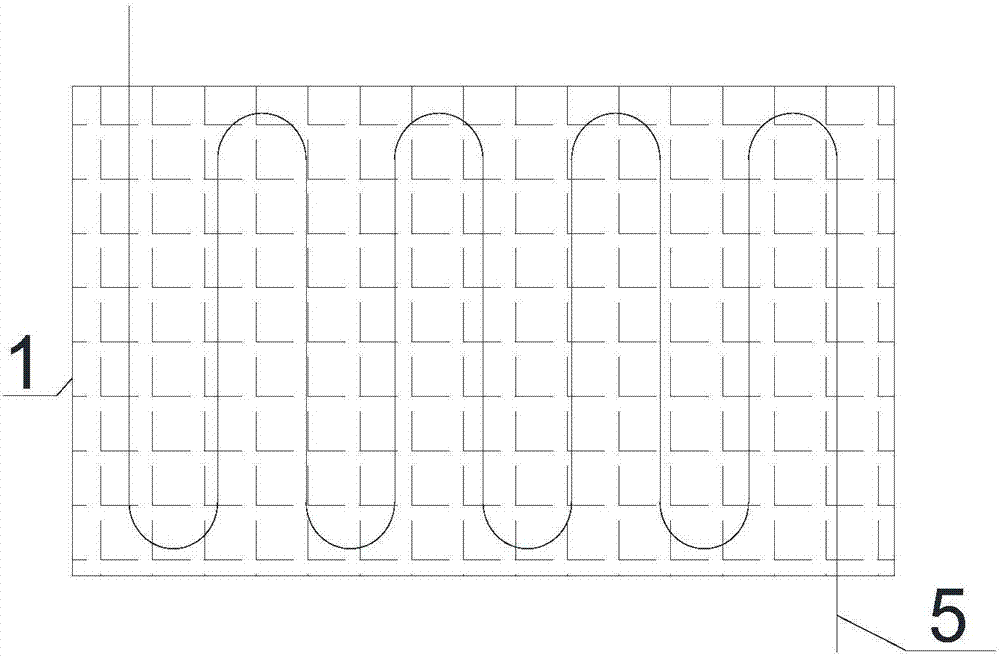

[0020] The present invention forms a complete bridge deck pavement structure with an adhesive layer 1 , a cast-in-place layer 2 , a waterproof layer 3 , a bridge deck pavement layer 4 and a carbon fiber heating element 5 . Wherein, the bonding layer 1 is formed by blending thermoplastic polymer material, curing agent and aggregate in a certain proportion and order.

[0021] Thermoplastic polymers are high molecular polymers that soften when heated, solidify when cooled, and can be softened again. Thermoplastic polymers are plastic when heated and softened, and return to a solid state when cooled. This phenomenon can be repeated alternately, so it can be recycled and reused. Thermoplastic polymers may be, for example, polyethylene, polypropylene, polystyrene, polyurethane, and the like...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap