Infrared thermal imaging air tightness tester

A technology of infrared thermal imaging and tester, which is applied in the direction of fluid tightness test, machine/structural component test, instrument, etc. It can solve the problems of ultrasonic method and achieve the effect of fast response speed and high temperature resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

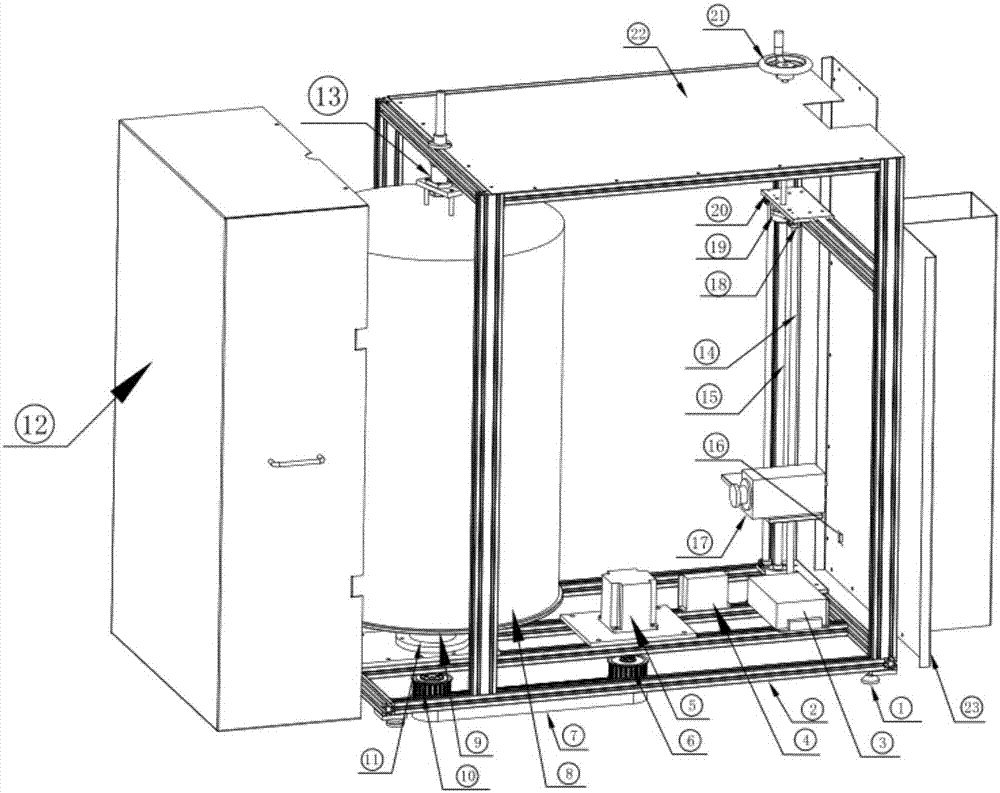

[0020] Such as figure 1 As shown, the infrared thermal imaging air tightness tester includes a test module, a control module, a thermal imaging module, a motion module, a data processing module and a tester frame. The tester frame includes a base plate, a support frame and an upper sealing plate; a foot is provided on the side of the base plate close to the ground, and one end of the foot is fixed on the base plate, and a rubber pad is provided at the other end, which can well buffer and reduce the The impact of possible external vibrations on the tester.

[0021] The test module includes a container to be tested, a turntable, a bearing seat, and a pressing rotating shaft. The container to be tested is cylindrical, and the upper end of the container to be tested is fixedly connected to the pressing shaft. The pressing shaft is fixed on the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com