A wavelength-tunable Bosa and its temperature control method

A temperature control method and wavelength technology, applied in the field of optical communication, can solve the problems of poor adjustment accuracy, slow wavelength adjustment and temperature speed, and difficulty in stabilizing the working temperature of the laser chip, and achieve the effect of improving the adjustment response rate and wavelength adjustment accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

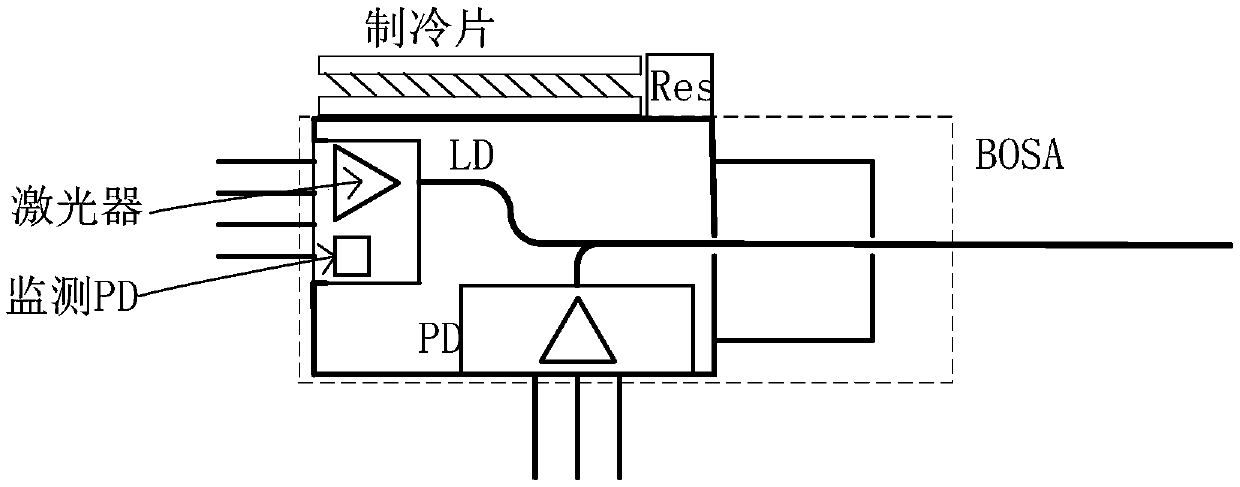

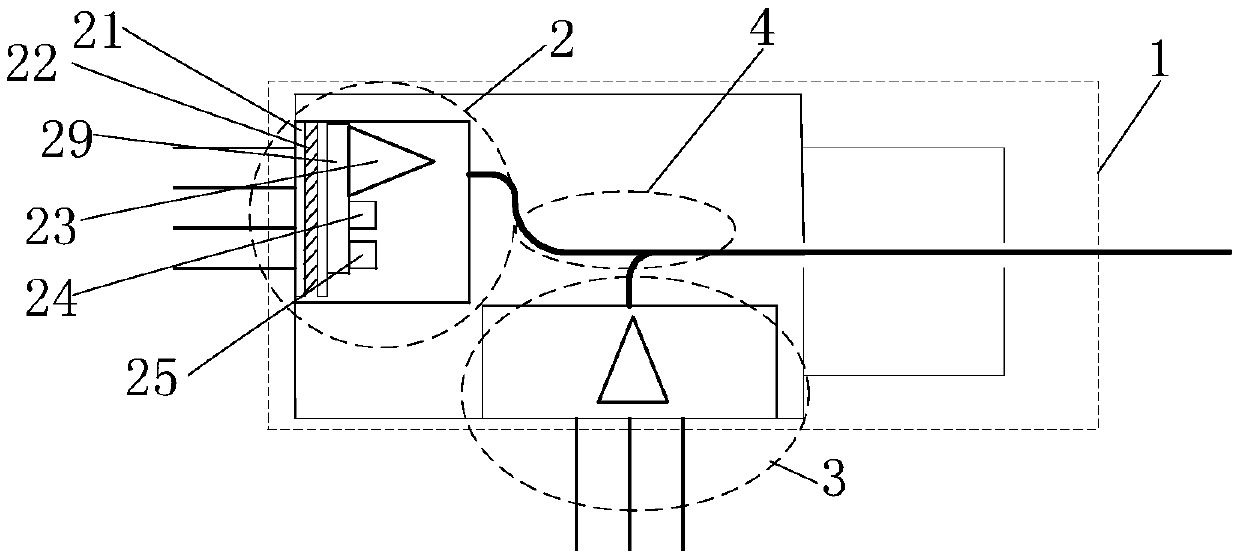

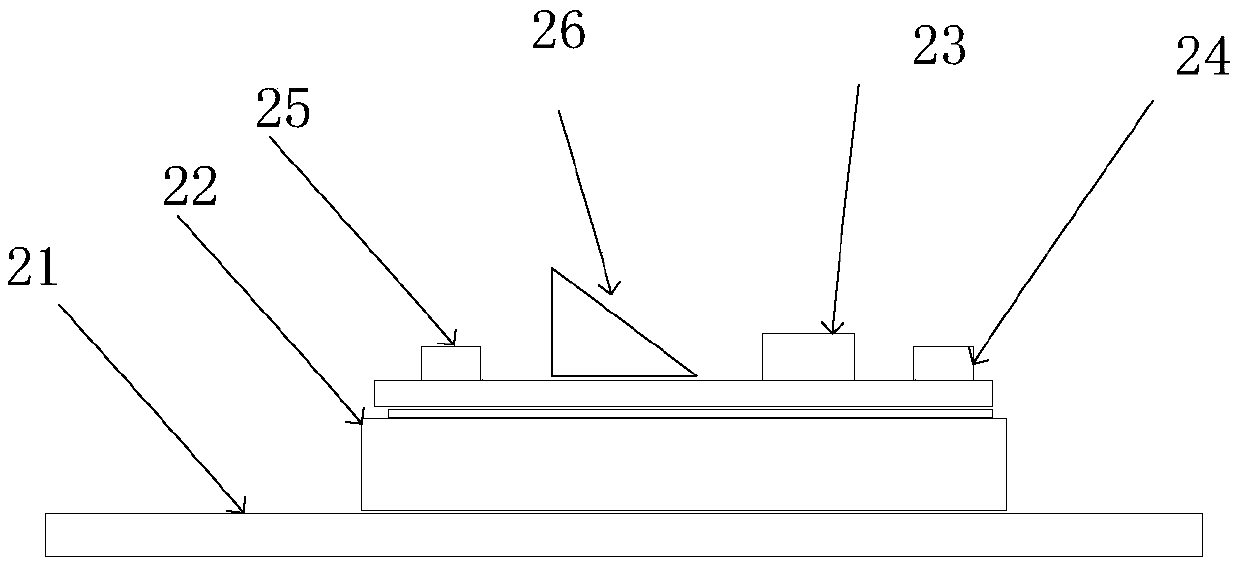

[0068] Embodiment 1 of the present invention provides a BOSA with tunable wavelength, such as figure 2 with image 3 As shown, it includes a BOSA housing 1, a transmitting module 2, a receiving module 3 and a BOSA receiving and receiving optical circuit assembly 4. The transmitting module 2 includes a base 21, a first cooler 22, a laser 23, a backlight PD24, a first thermal A sensitive resistor 25 and a 45° reflective prism 26, wherein the base 21 is provided with at least 8 pins, corresponding to the TEC+ and TEC- pins of the first refrigerator 22, and the LD+ and LD- pins of the laser 23 , the PD+ and PD- pins of the backlight PD24, and the RES1 and RES2 pins of the first thermistor, specifically:

[0069] The bottom of the first refrigerator 22 is fixed on the base 21 by heat-conducting glue, and the position of the 45° reflective prism 26 is located on the surface of the first refrigerator 22 after the fixing is completed, and relative to the central area of the base 2...

Embodiment 2

[0077] Embodiment 2 of the present invention provides a BOSA with tunable wavelength, such as figure 2 with Figure 4 As shown, it includes a BOSA shell 1, a transmitting module 2, a receiving module 3 and a BOSA receiving and receiving optical circuit assembly 4. The transmitting module 2 includes a base 21, a first cooler 22, a laser 23, a backlight PD24, a first thermal A sensitive resistor 25 and a 45° reflective prism 26, wherein at least 8 pins are arranged on the base 21, respectively corresponding to the TEC+ and TEC- pins of the first refrigerator 22, and the LD+ and LD- pins of the laser 23 , the PD+ and PD- pins of the backlight PD24, and the RES1 and RES2 pins of the first thermistor, specifically:

[0078] The bottom of the first refrigerator 22 is fixed on the base 21 by heat-conducting glue, and the position of the laser 23 is located in the central area of the surface of the first refrigerator 22; The 45° reflective prism 26 is provided on the light-emitti...

Embodiment 3

[0096] In addition to providing the 45° reflective prism described in Embodiment 2, the wavelength-adjustable BOSA that uses the 45° reflective prism to realize the horizontal emission of laser light and complete the vertical output of light (wherein "horizontal" and "vertical" are relative to the base of the emitting component On the surface), embodiment 3 of the present invention also provides a BOSA with adjustable wavelength for vertical light output on the basis of vertical emission of laser light, such as figure 2 , Figure 9 with Figure 10 As shown, it includes a BOSA shell 1, a transmitting module 2, a receiving module 3 and a BOSA receiving and receiving optical circuit assembly 4. It is characterized in that the transmitting module 2 includes a base 21, a coupling platform 27, a first refrigerator 22, a laser 23. The backlight PD24 and the first thermistor 25, wherein at least 8 pins are provided on the base 21, respectively corresponding to the TEC+ and TEC- pins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com