Harmonic staring type wound brushless doubly-fed machine

A doubly-fed motor, winding technology, applied to the shape/style/structure of winding conductors, electrical components, electromechanical devices, etc., can solve the problems of inability to increase starting torque and reduce starting current, etc., to achieve broad industrial Effects of application prospect, good starting performance and high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

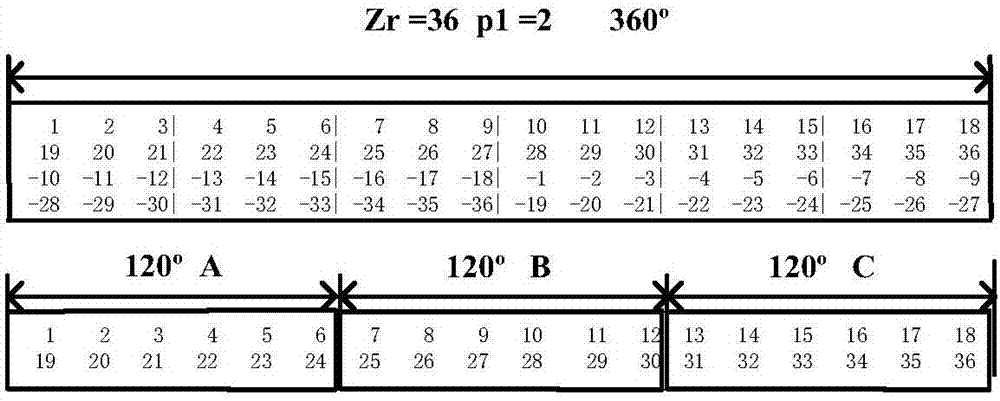

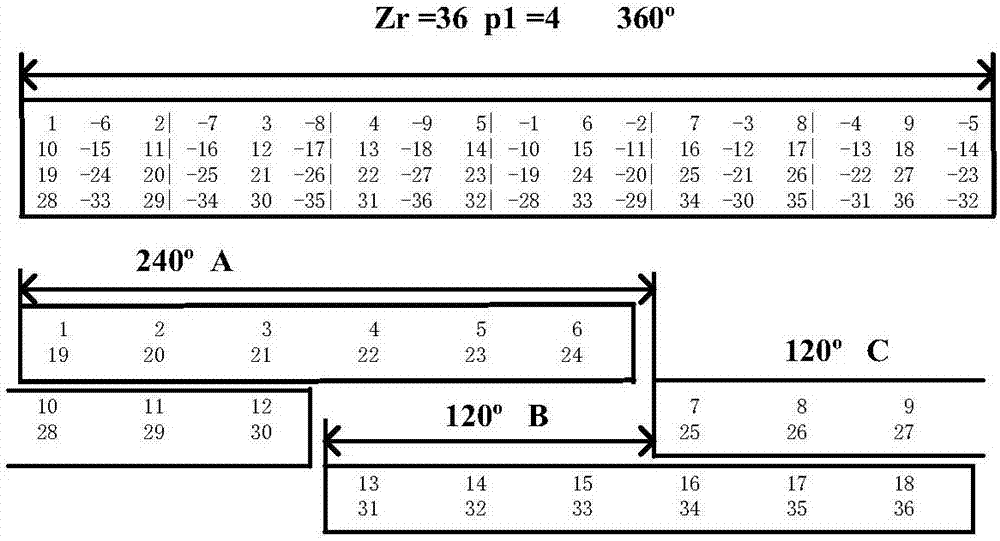

[0033] Select the number of pole pairs of a power winding as p 1 = 2,p 2 = 4, the rotor is 36-slot brushless doubly-fed motor as an example, the rotor winding is divided into p 1 +p 2 = 6 groups, p 1 = 2, p 2 = the greatest common divisor of 4 d=2, get (p 1 +p 2 ) / d=3 is an odd number, according to the above theory, there are 1st, 4th, 2nd, 5th and 3rd, 6th groups of groove numbers, and the induced electromotive forces are all in the same phase under the 4th and 2nd pole pairs, such as figure 1 , figure 2 shown. Here each group is connected by 6 equal turns.

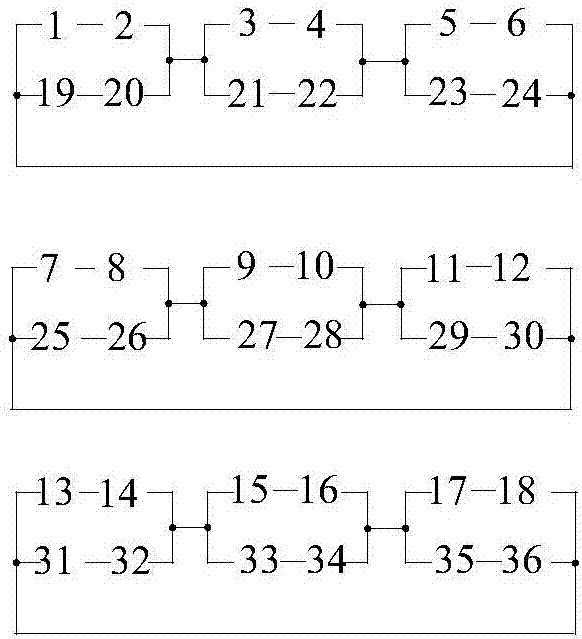

[0034] If it is a conventional brushless doubly-fed motor, the winding connection diagram is as follows: image 3 shown. 2 slot number groups in p 1 = 2, p 2 = 4 The induced electromotive force under the pair of poles is formed by series connection of coil groups with the same phase, so any connection point is designated as the potential reference point, and the potentials of all connection points are zero. ...

Embodiment 2

[0082] Select the number of pole pairs of a power winding as p 1 = 1,p 2 = 3, the rotor 48-slot brushless doubly-fed motor as an example, the rotor winding is divided into (p 1 +p 2 )=4 groups, d=1 is an odd number, according to the above theory, there is a phase difference of kπ between the first group and the third group of slot numbers, where k is an odd number, then the third group of slot numbers is reversed and connected in series with the first group . In the same way, the slot numbers of the fourth group are reversed and connected in series with the second group. The corresponding rotor winding connection diagram of the motor is shown in Figure 8 shown. Here each group is connected by 6 equal turns.

[0083] Therefore, the brushless doubly-fed motor of the present invention has good starting performance and operating efficiency, and is a very ideal rotor winding design method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com