Combined robot and its assembly method

An assembly method and robot technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of increasing operating costs and control difficulties, and achieve the effects of simple structure, convenient disassembly and assembly, and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

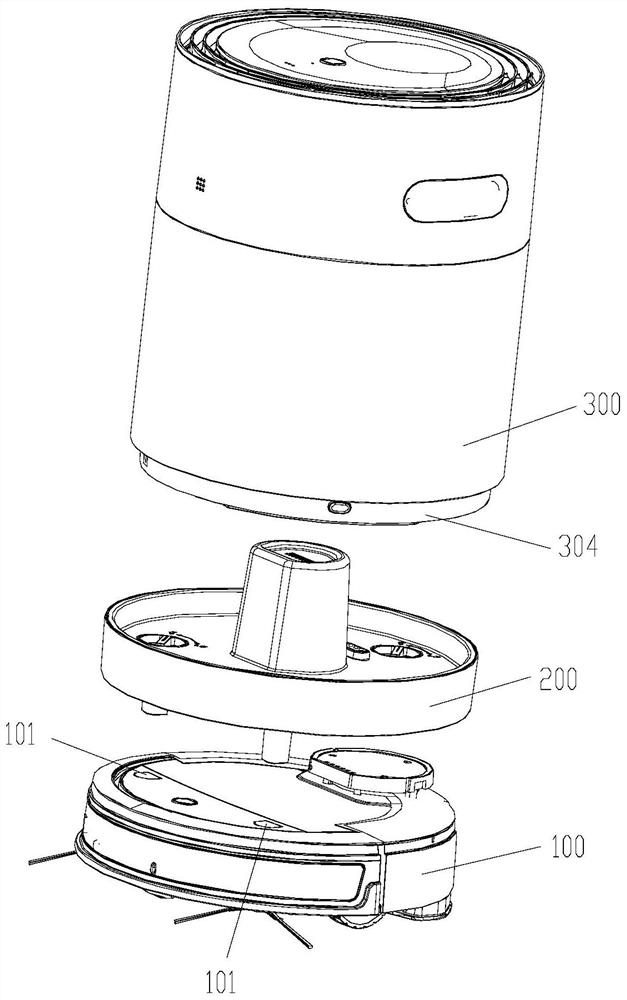

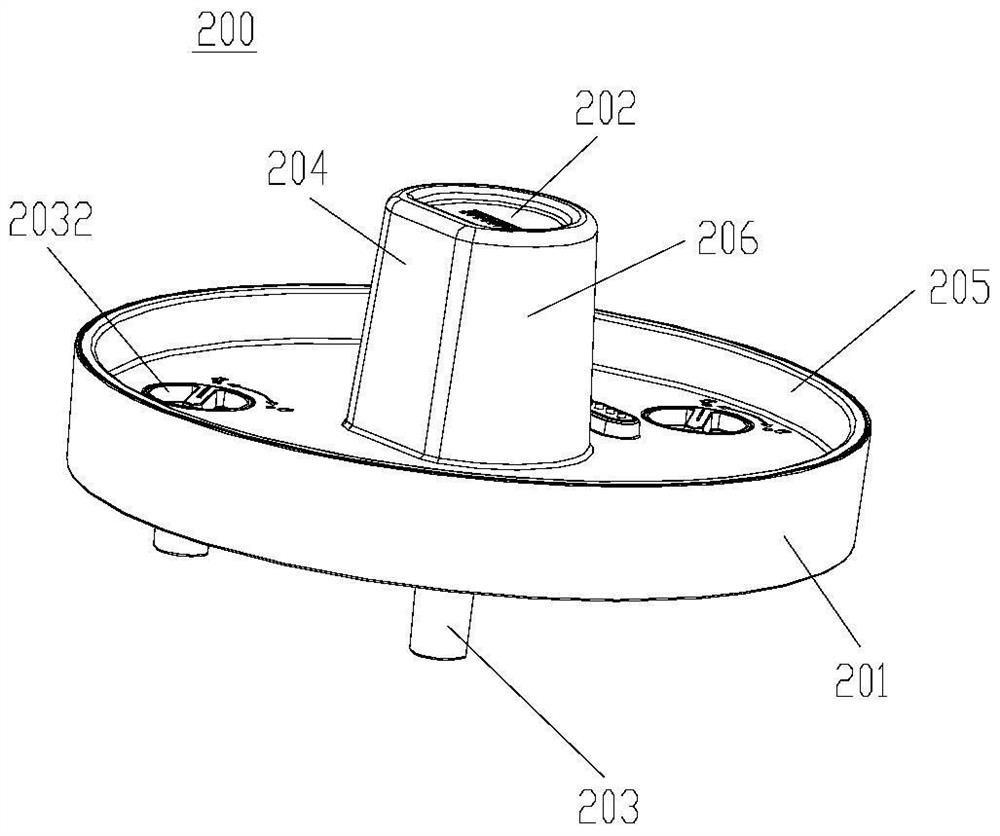

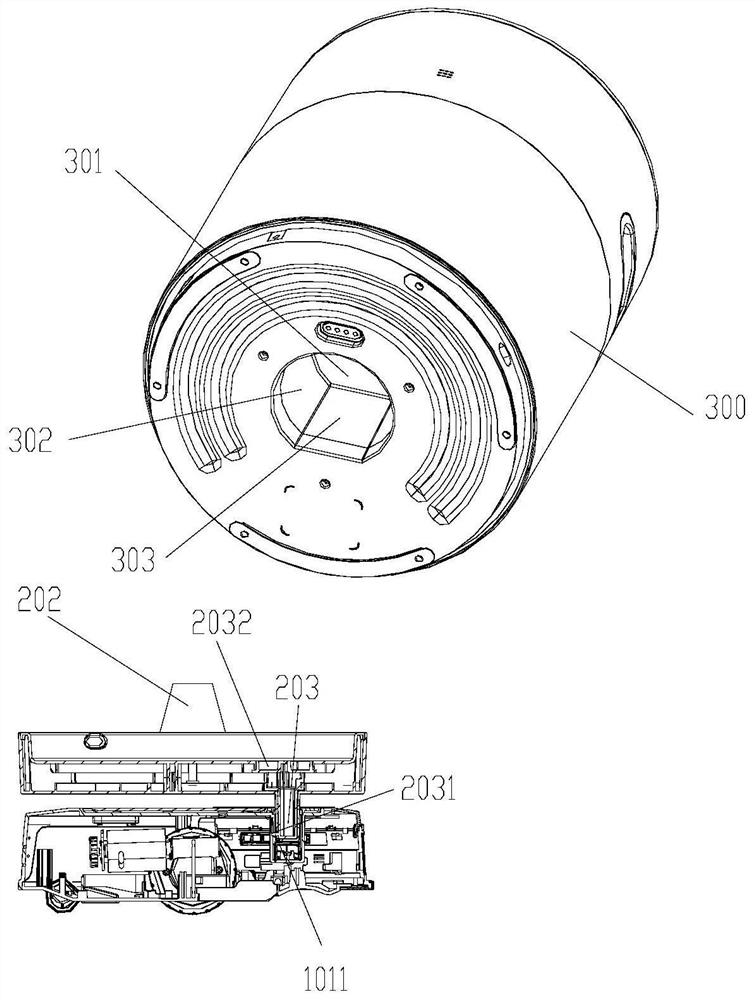

[0023] figure 1 It is a schematic diagram of the overall structure of the combined robot of the present invention; figure 2 It is a structural schematic diagram of the connector of the present invention; image 3 It is a schematic diagram of the overall structure of the self-mobile robot assembled with connectors of the present invention. Such as Figure 1 to Figure 3 As shown, the present invention provides a combined robot, including a self-mobile robot 100 and a functional module 300 connected thereto, the self-mobile robot 100 is provided with a control center (not shown in the figure), and the functional module 300 is connected to Components 200 are combined and connected to the upper part of the self-propelled robot 100, and the connecting components 200 are detachably connected to the self-propelled robot 100 and the functional module 300 respectively, and the control center controls the combined robot to work according to the combined state. The above-mentioned sel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com