Edge grinding system based on dynamic self-optimizing motion control technique

A motion control and self-optimization technology, applied in the field of grinding, can solve the problems of high labor intensity and unstable product quality, and achieve the effect of effective grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings of the description.

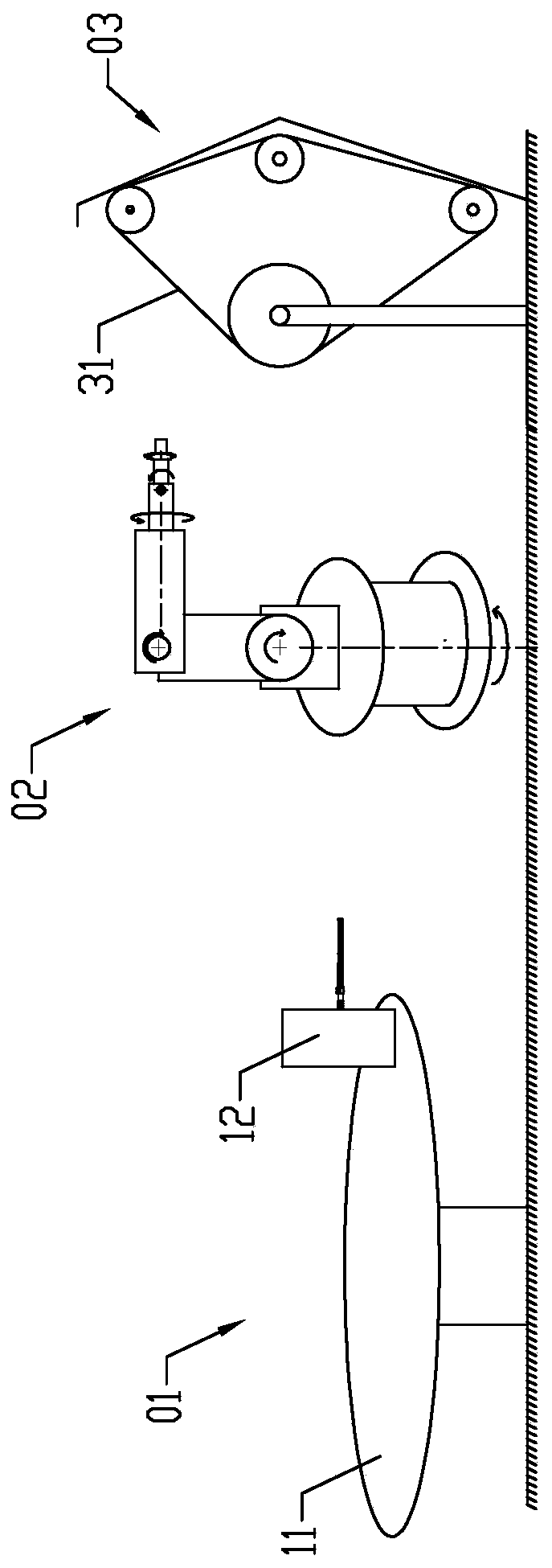

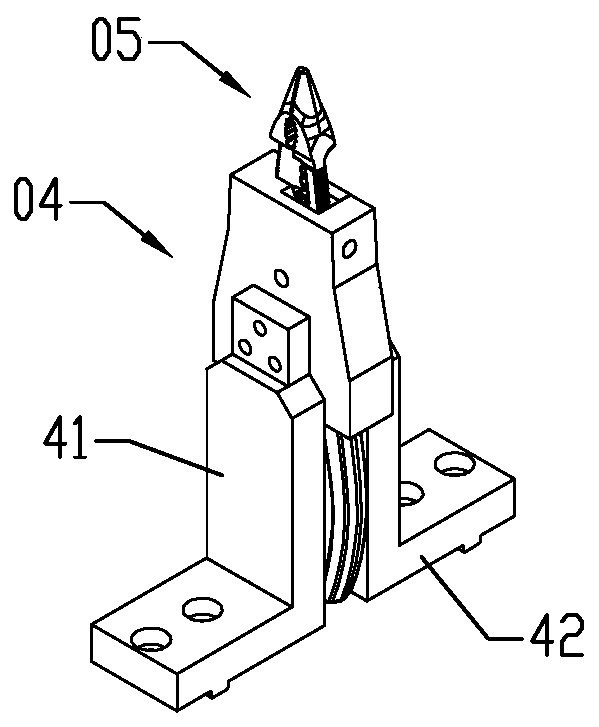

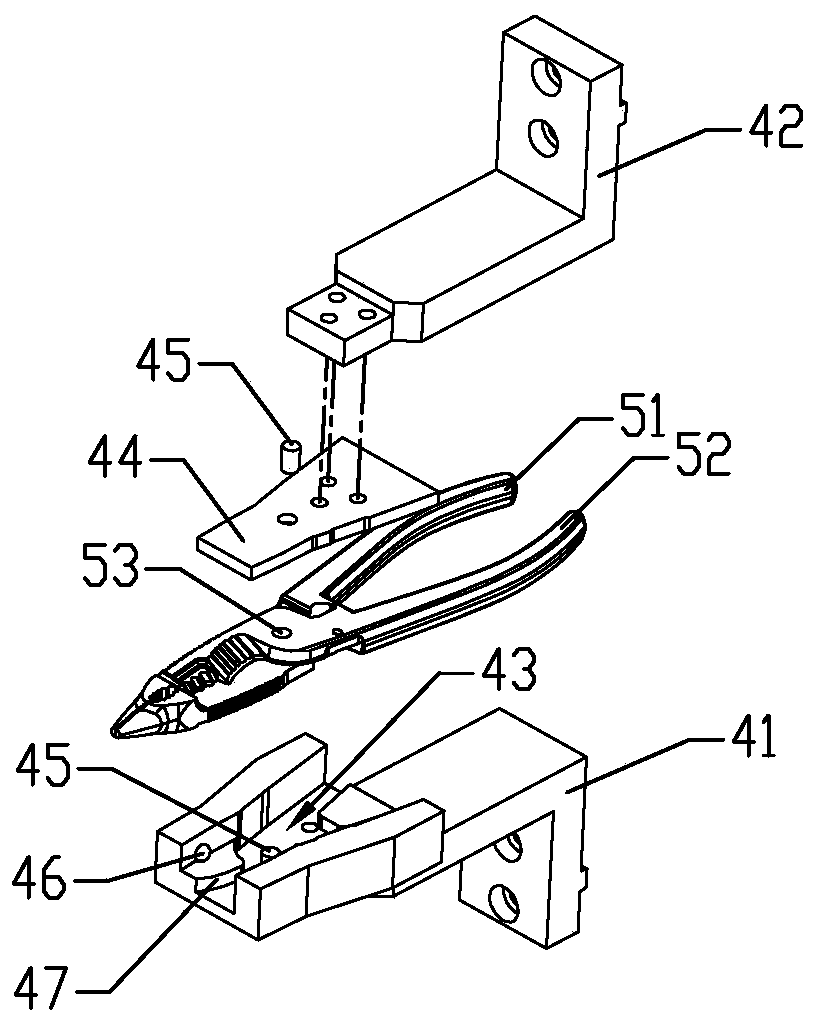

[0037] Such as figure 1 As shown, the edge grinding system based on dynamic self-optimizing motion control technology includes a feeding device 01, a robot 02 for realizing dynamic self-optimizing motion control, and a grinding device 03. The robot 02 is configured to clamp the workpiece from the feeding device and The clamp 04 that returns the workpiece to the feeding device, the clamp 04 includes a first clamping arm and a second clamping arm, the first clamping arm or / and the second clamping arm are driven to move in opposite directions to clamp the workpiece from the feeding device 01, the first clamping arm The arm or / and the second clamp arm are driven to return the workpiece to the feeder.

[0038] Based on the above scheme, the feeding device is used to transfer the workpiece, that is, the workpiece is transferred to be grabbed by the robot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com