Low-emission low-smoke density natural fiber-improved composite packing box

A technology of natural fiber and smoke density, applied in the field of packaging boxes, can solve problems such as poor sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

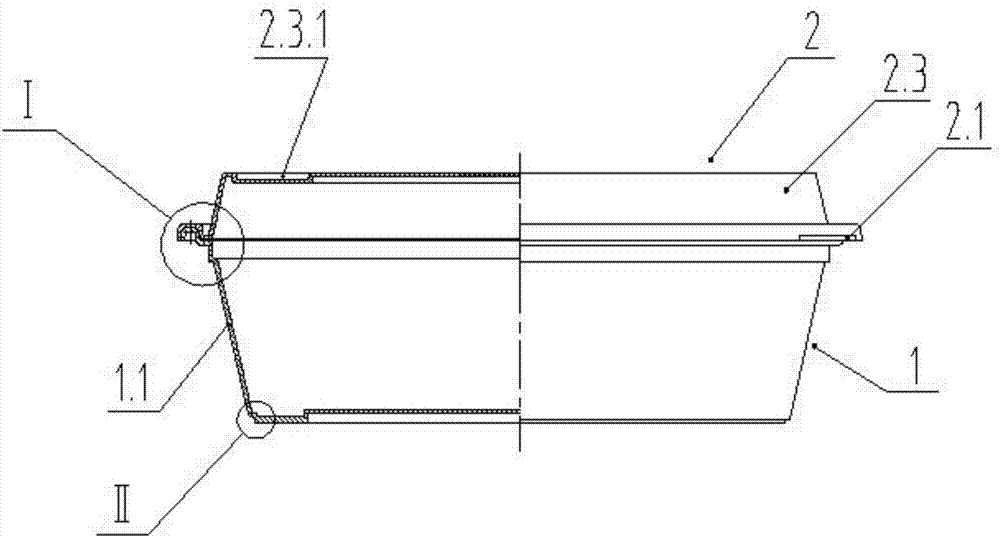

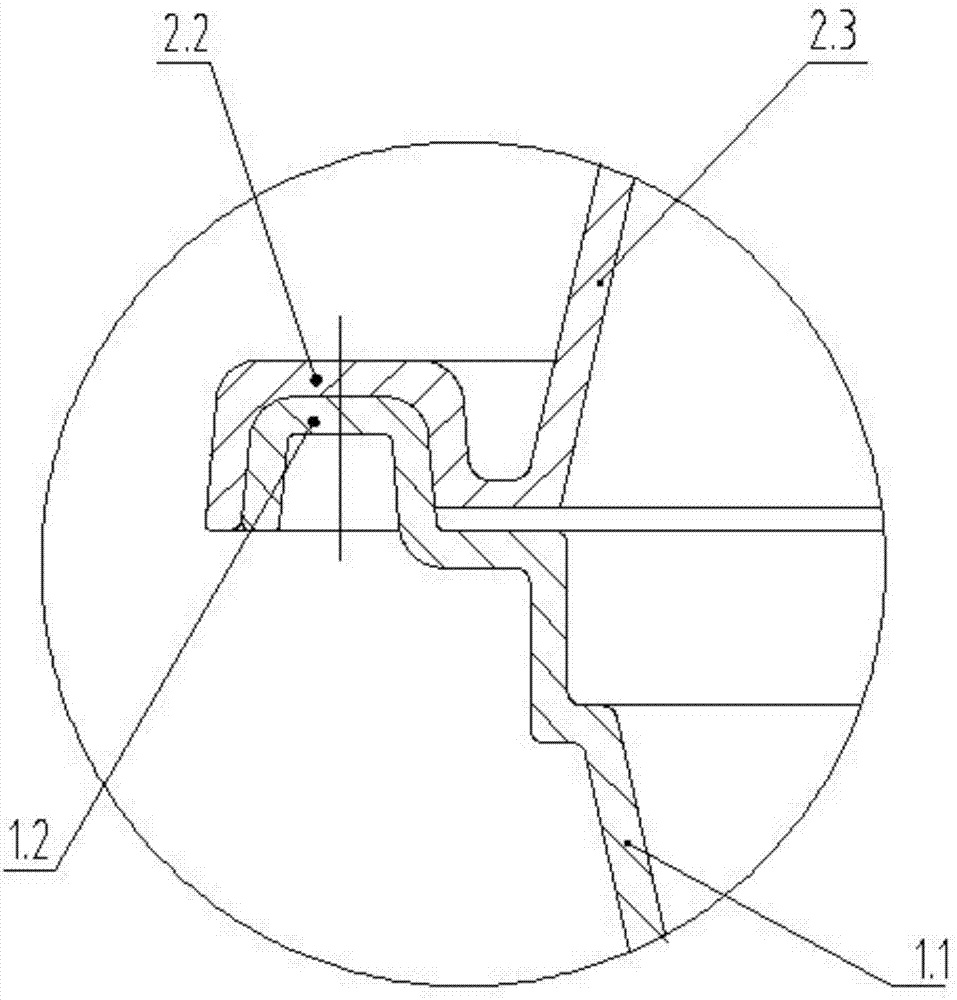

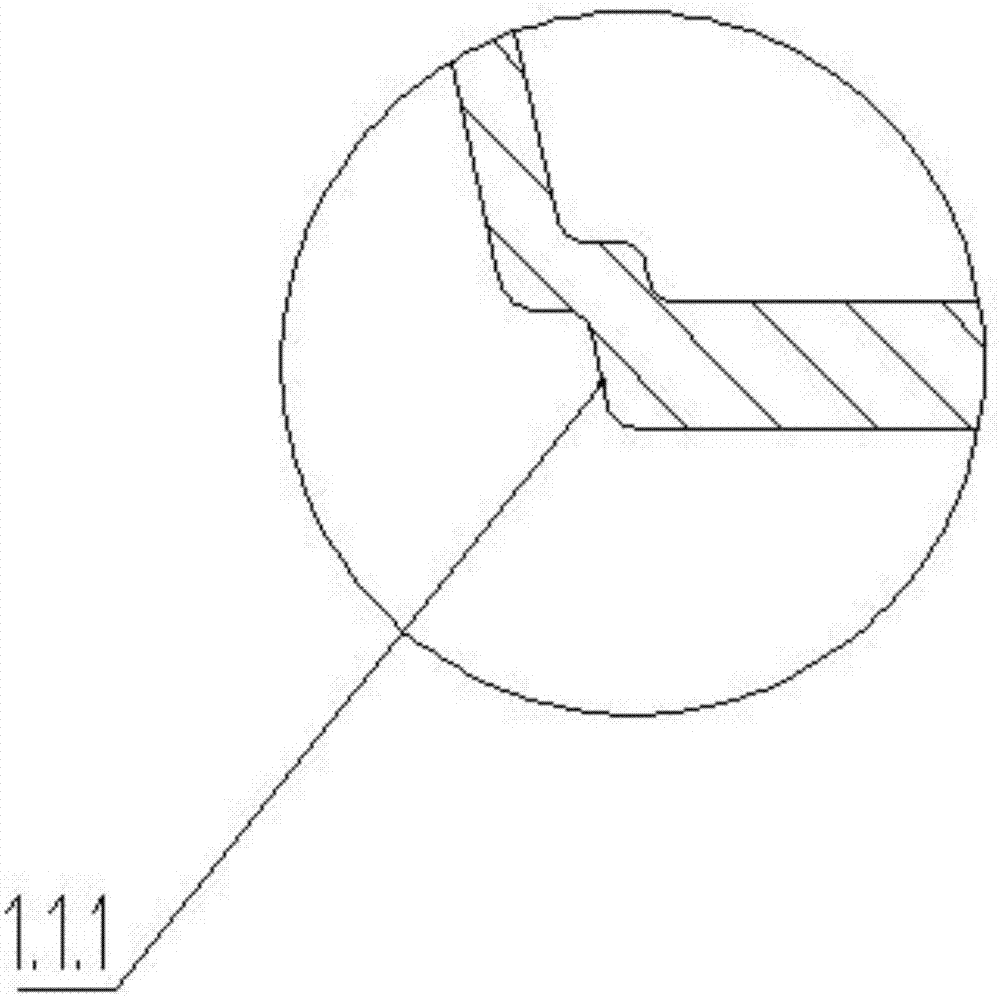

[0017] The low-emission and low-smoke density natural fiber modified composite packaging box shown in the attached figure includes a box body 1 and a box cover 2. The box body 1 and box cover 2 are made of low-emission and low-smoke density natural fiber modified composite board; the low-emission The low-smoke density natural fiber modified composite board is composed of a wear-resistant layer and a base material from the outside to the inside. The base material is composed of natural fiber and PVC base material; Ⅰ1.1 surrounding edge Ⅰ1.2; box cover 2 includes the central protrusion Ⅱ2.3, the surrounding rim Ⅱ2.2 of the protrusion Ⅱ2.3; box body 1 ring edge Ⅰ1.2, box cover 2 ring edge The cross section of II2.2 is conical; when the lid 2 protrudes II2.3 on the ring edge II2.2 and fits on the box body 1, the ring edge II2.2 of the box c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com