Measurement method of intrinsic viscosity of polyacrylonitrile-based polymer solutions and protofilaments

A polyacrylonitrile-based, fiber-specific technology, applied in the field of polymers, can solve the problems of difficult measurement of intrinsic viscosity of various polymers, narrow measurement range, poor applicability, etc., to achieve accurate and controllable testing process, good applicability, comparable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Required reagents and materials

[0048] NaSCN; chromatographically pure DMF; formic acid;

[0049] Required equipment

[0050] SCHOTT 532 10 / I Ubbelohde capillary viscometer;

[0051] SCHOTT Viscometer;

[0052] (G 4 funnel);

[0053] operation process

[0054] The polymer is hydraulically formed into a thin film, transferred to formic acid with a temperature of 40-80°C and a mass fraction of 5% for 30 minutes, and then transferred to desalted water at a temperature of 40-80°C for 3 times, 30 minutes each time, to remove Solvent; then place the polymer film in an oven at 80-110°C to dry it completely (the oil should be removed before the original silk fiber test).

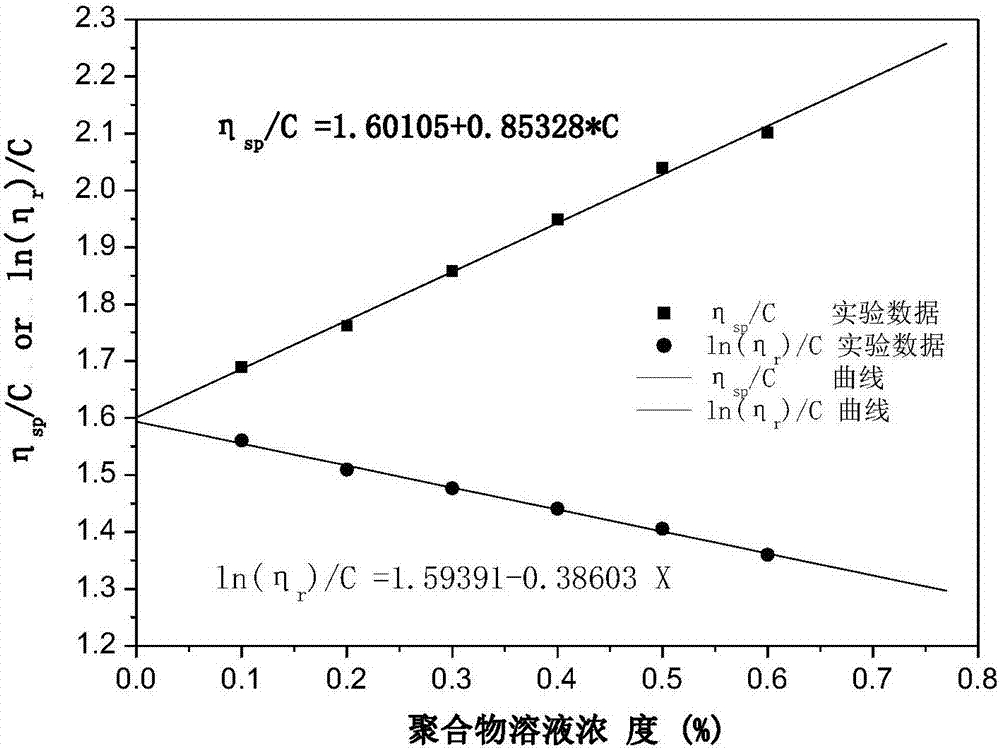

[0055] A series of polymer solutions with different concentrations were prepared by using 0.1000M sodium thiocyanate DMF as solvent. After the sample is completely dissolved, use G 4 The prepared polymer solution was filtered through a funnel, and the filtrate was transferred to an Ubbelohde viscosi...

Embodiment 2

[0067] Required reagents, materials, instruments and equipment are the same as in Example 1; the operating steps are the same as in Example 1.

[0068] Table 4 Intrinsic viscosity data of the same sample measured at different times

[0069] Measurement date

[0070] It can be seen from Table 4 that the standard deviation of the sample is 0.0063 for the same polymerization liquid sample produced by Lanzhou Bluestar Fiber at different times and measured by different analysts, indicating that the results are accurate and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com