Method for testing density of polyacrylonitrile protofilament fibers

A technology with dense fibers and polyacrylonitrile, applied in the field of carbon fiber, can solve the problems of no standard rules and large errors, and achieve the effects of accurate and reliable results, strong comparability, and accurate and controllable testing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

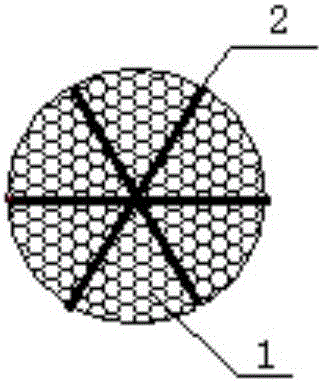

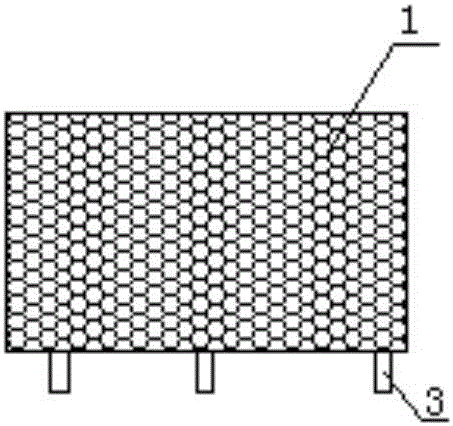

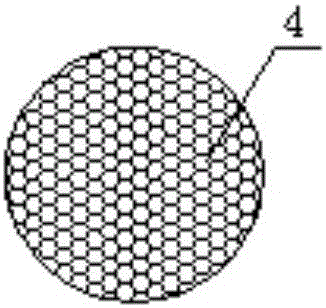

Image

Examples

Embodiment 1

[0048] Weigh iodine, potassium iodide, acetic acid and 2,4-o-chlorophenol and dissolve them in 1L of high-purity water to prepare 0.2mol / L iodine solution. The molar ratio of iodine to potassium iodide, acetic acid and 2,4-o-chlorophenol is: 1:3 :7.5:0.3. Then the configured solution was transferred to a 2-liter beaker, and the iodine solution was heated to 60 degrees and stirred for 15 minutes. Weigh 8 different quality fiber bundles from the same batch, place them in a stainless steel cylinder in turn, immerse the cylinder in iodine solution, and stir gently for 50 minutes. Afterwards, the soaked fiber and the cylinder were taken out of the iodine solution, and the sample was sprayed and washed with desalted water at a flow rate of 0.5 L / min for 30 minutes until the water was colorless. Take out the cleaned fiber samples from the cylinder, put them into centrifuge tubes one by one, centrifuge at a speed of 4000 rpm for 40 minutes, and dry the washed samples by centrifugatio...

Embodiment 2

[0052]The preparation of iodine solution is as described in Example 1. Weigh 5 fiber samples of the same batch with a mass of 0.15 ± 0.01 g, put them in a stainless steel cylinder in turn, then soak them in iodine solution, and stir gently for 60 minutes. Afterwards, the soaked fiber and the cylinder were taken out of the iodine solution, and the sample was sprayed and washed with desalted water at a flow rate of 0.5 L / min for 50 minutes until the water was colorless. The fiber samples after washing are taken out from the cylinder, put into centrifuge tubes one by one, centrifuged at a speed of 4000 rpm for 60 minutes, and the washed samples are centrifuged to dry. Put the centrifuged fiber sample into a titration cup, add 80 ml of 50°C DMSO, and stir the sample on a magnetic stirrer until it is completely dissolved. With 0.1mol / L AgNO 3 The standard solution is subjected to potentiometric titration on an automatic titrator, the titration adopts linear titration, the titrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com