Manufacturing method of electromagnetic wave shielding film for flexible printed circuit board

A manufacturing method and shielding film technology, applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, applications, etc., can solve the problems of raw material loss, product yield and physical property decline, and achieve increased productivity, shortened manufacturing processes, and improved economics. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

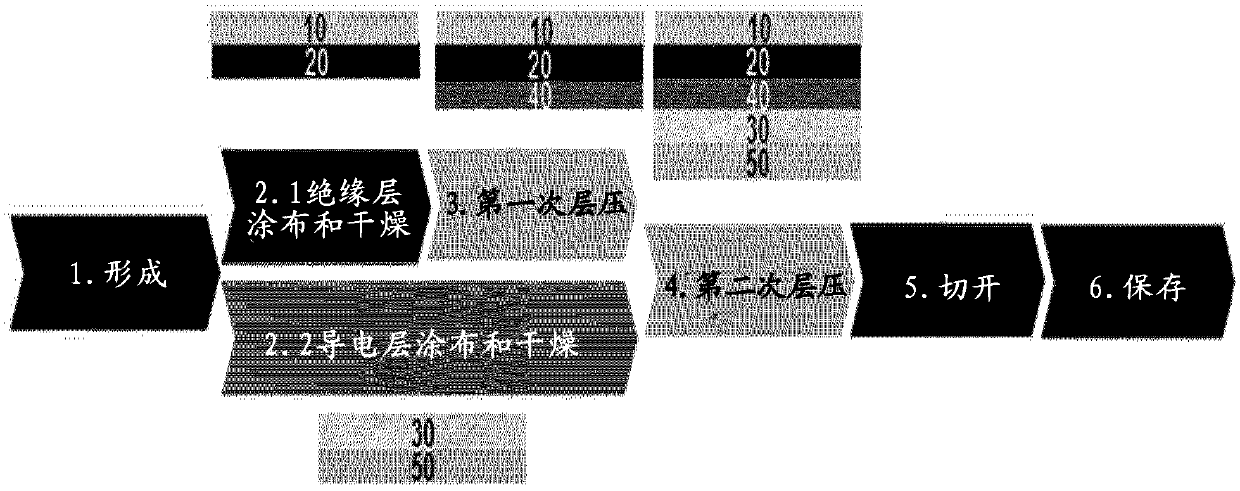

Method used

Image

Examples

Embodiment 1

[0123] 1-1. Production of insulating layer coating liquid

[0124] The following substances were mixed and dissolved to prepare an insulating layer coating liquid: 9.1% by weight of a halogen-free non-flexible epoxy resin (Kukusu Chemical KDP555) as a thermosetting resin, 8.1% by weight of a bisphenol A type epoxy resin (Dow DER 383), low Dielectric epoxy resin (Nippon XD1000) 3.5% by weight, bisphenol novolac epoxy resin (KPBN110) 6.1% by weight, carbon black (Columbia (Columbian) chemical) 0.9% by weight, phosphorus flame retardant (Otsuka Chemical SPB-100) 4.8% by weight, thermoplastic resin rubber (Kumho Petrochemical KNB 40H) 24.2% by weight, polyvinyl butyral resin (UNO Chemical KS23Z) 12.1% by weight, dicyandiamide as a latent curing agent 10.7% by weight, 0.6% by weight of an imidazole derivative (Ildong Chemical 2E4MZ) as a catalyst-type curing agent, and 9.8% by weight of methyl cellosolve as a solvent.

[0125] 1-2. Preparation of conductive adhesive layer coat...

Embodiment 2-4

[0134] The electromagnetic wave shielding film for flexible printed circuit boards was manufactured by the method similar to the said Example 1 except having changed the thickness of the electrolytic copper foil of the separation-type double-layer copper foil as shown in following Table 1.

[0135] At this time, in Examples 2 to 3, 2 μm electrolytic copper foil (Mitsui (Japan), 2 μm electrolytic copper foil) and 3 μm electrolytic copper foil (Mitsui (Japan), 3 μm electrolytic copper foil) composed of separate double layers were used, respectively. ), and 6 μm rolled copper foil (Mitsui (Japan), 6 μm electrolytic copper foil) composed of a copper single layer was used in Example 4, respectively.

Embodiment 5

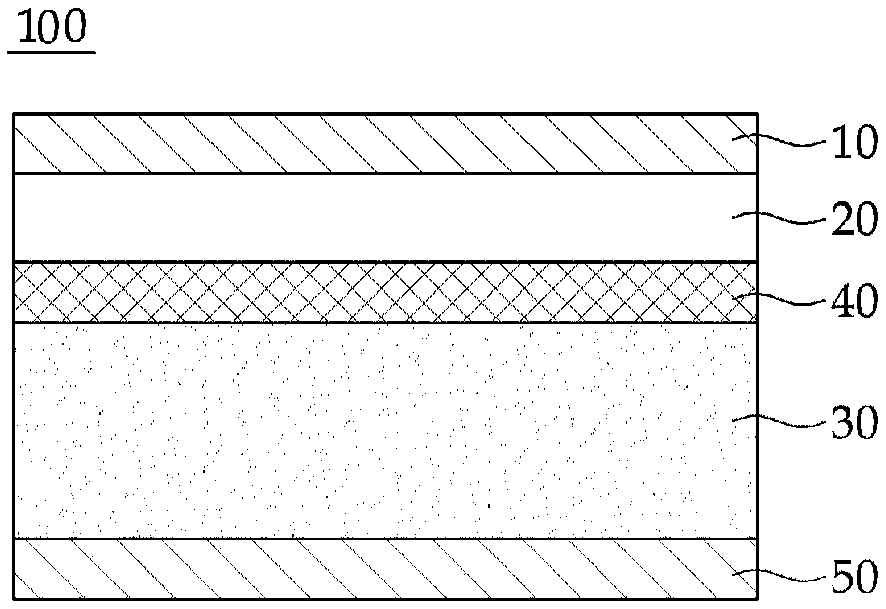

[0137] An insulating layer was formed on the first surface of the first substrate film by microgravure coating using the insulating layer coating composition produced in Example 1-1, and dried at 130° C. for 3 minutes and 30 seconds, An insulating layer of 5 to 6 μm in a semi-cured state was formed.

[0138] By comma coating, using the conductive adhesive layer composition produced in Example 1-2, a conductive adhesive layer was formed on the first surface of the second base film prepared later, and dried at 130° C. for 3 In minutes and 30 seconds, a semi-cured conductive layer of 14 to 15 μm was formed.

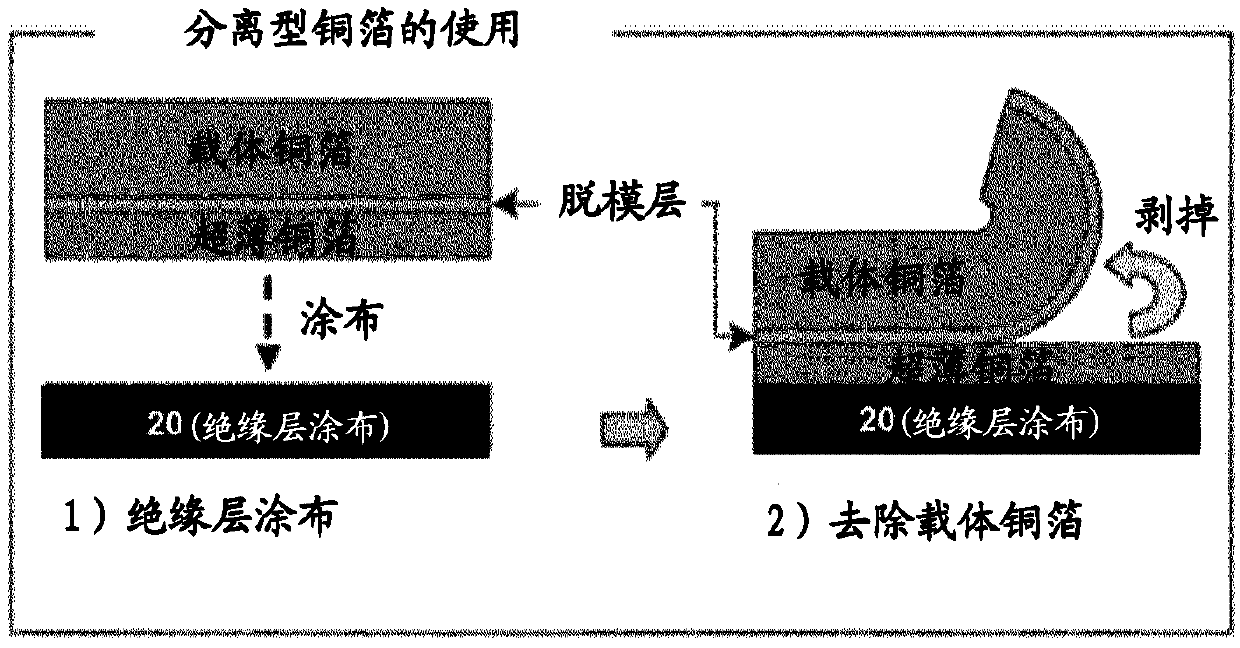

[0139] Use separation-type (Peelable) double-layer copper foil [electrolytic copper foil (1μm) + separation layer + carrier copper foil (35μm), Olin Brass (USA), 1μm electrolytic copper foil), on the first substrate film After bonding the second copper foil of the split-type double-layer copper foil to the insulating layer, the first copper foil of the carrier was removed. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com