vacuum valve

A vacuum valve and valve seat technology, applied in valve details, valve devices, sliding valves, etc., can solve the problems of high cost of vacuum valves, unit consumption of driving components and guiding components, etc., and achieve the effect of simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

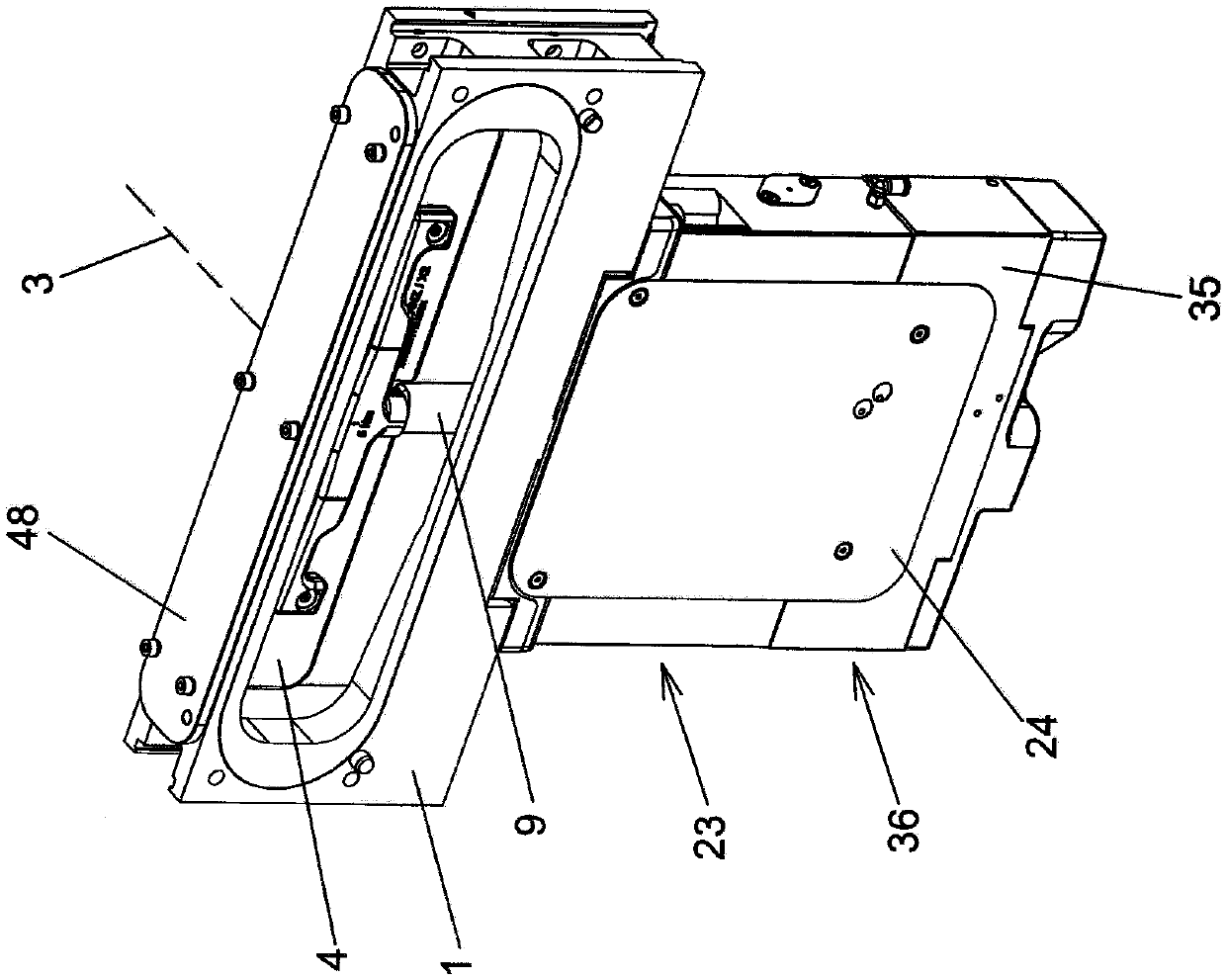

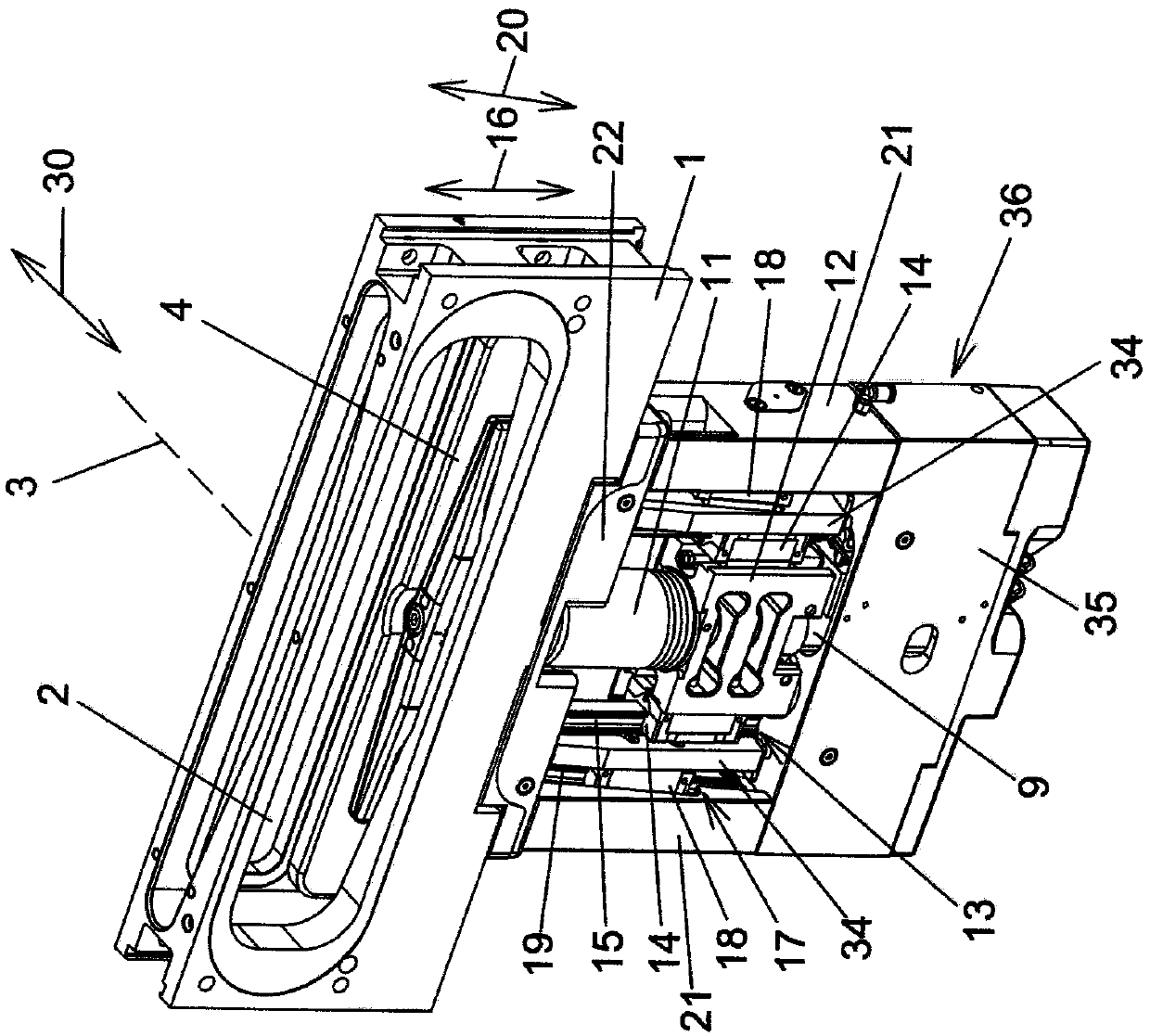

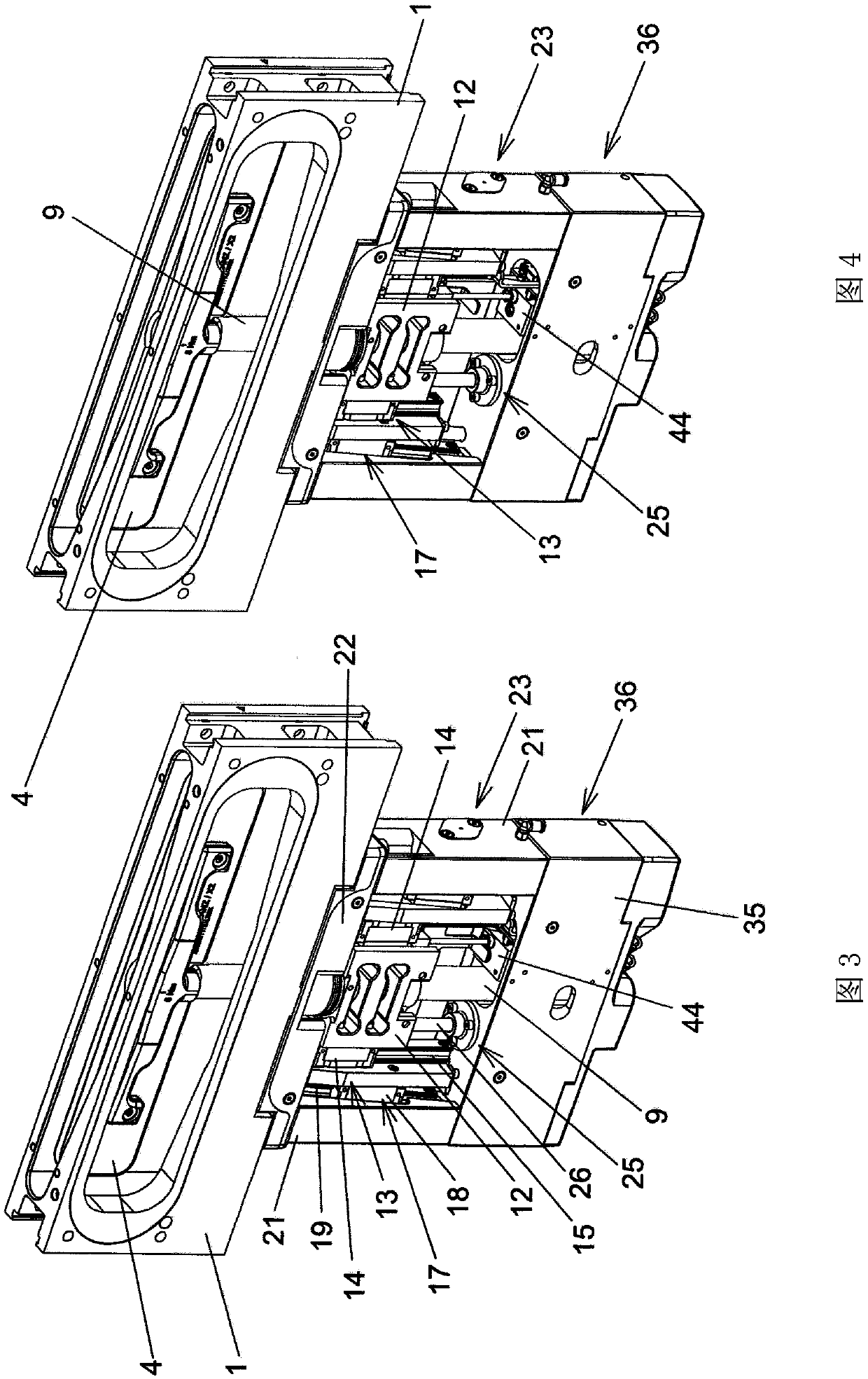

[0036] An exemplary embodiment of a vacuum valve according to the invention is shown in the drawing.

[0037] The vacuum valve has a valve body 1 with a wall having a valve opening 2 with an axis 3 . In the closed state of the vacuum valve, the valve opening 2 is closed by an in particular plate-shaped closing member 4 , which is then in its closed position. In the closed position of the closing member 4 , it is pressed against a valve seat 5 , which surrounds the valve opening 2 on the side facing the closing member 4 . In the open state of the vacuum valve, the closing member 4 releases the valve opening 2 and the closing member 4 is then in its open position. The movement of the closing member 4 between the closed position and the open position takes place via an intermediate position in which the closing member covers the valve opening 2 as viewed on the axis 3 of the valve opening 2, but from the valve Remove (= disengage) from seat 5.

[0038] In order to seal between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com