polarizing element

A polarizing element and established technology, applied in polarizing elements, optical elements, instruments, etc., can solve the problems of difficulty in maintaining reliability and high difficulty, and achieve the effect of improving light transmission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0047]

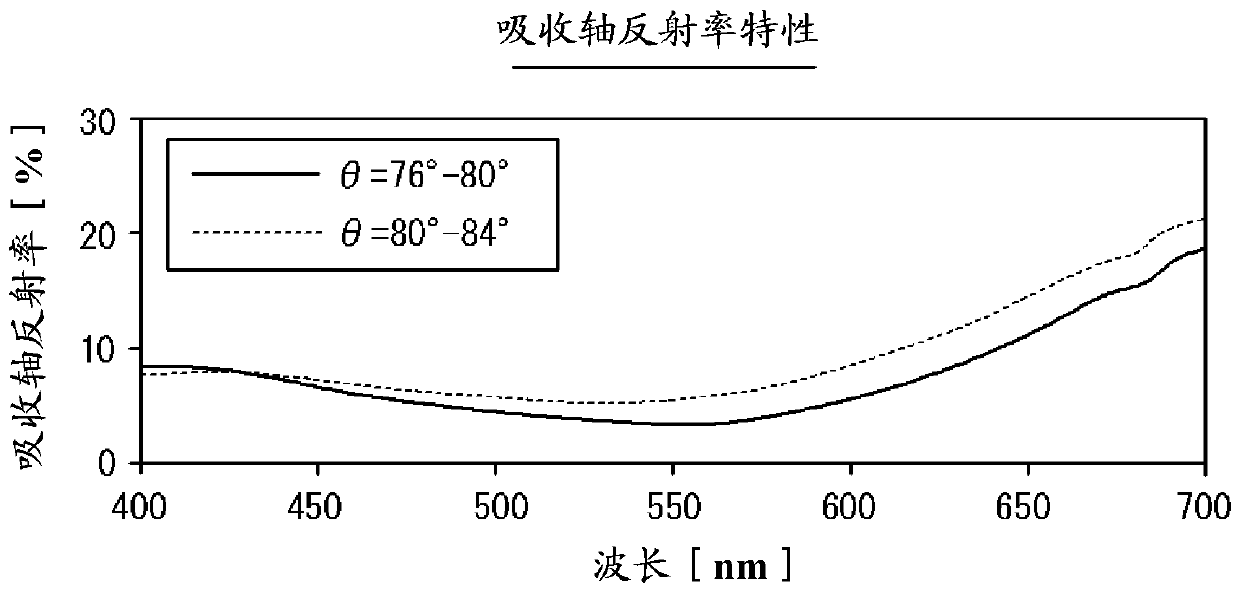

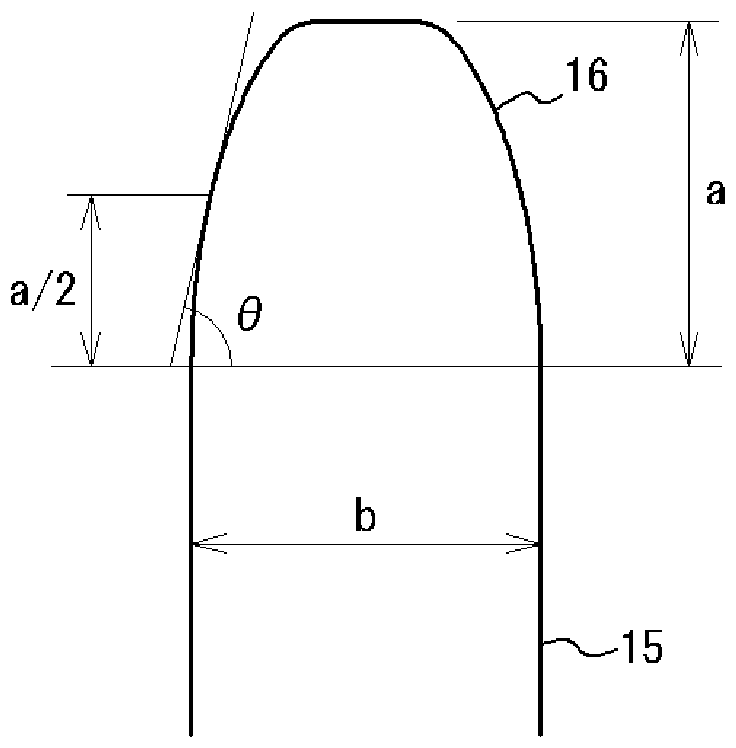

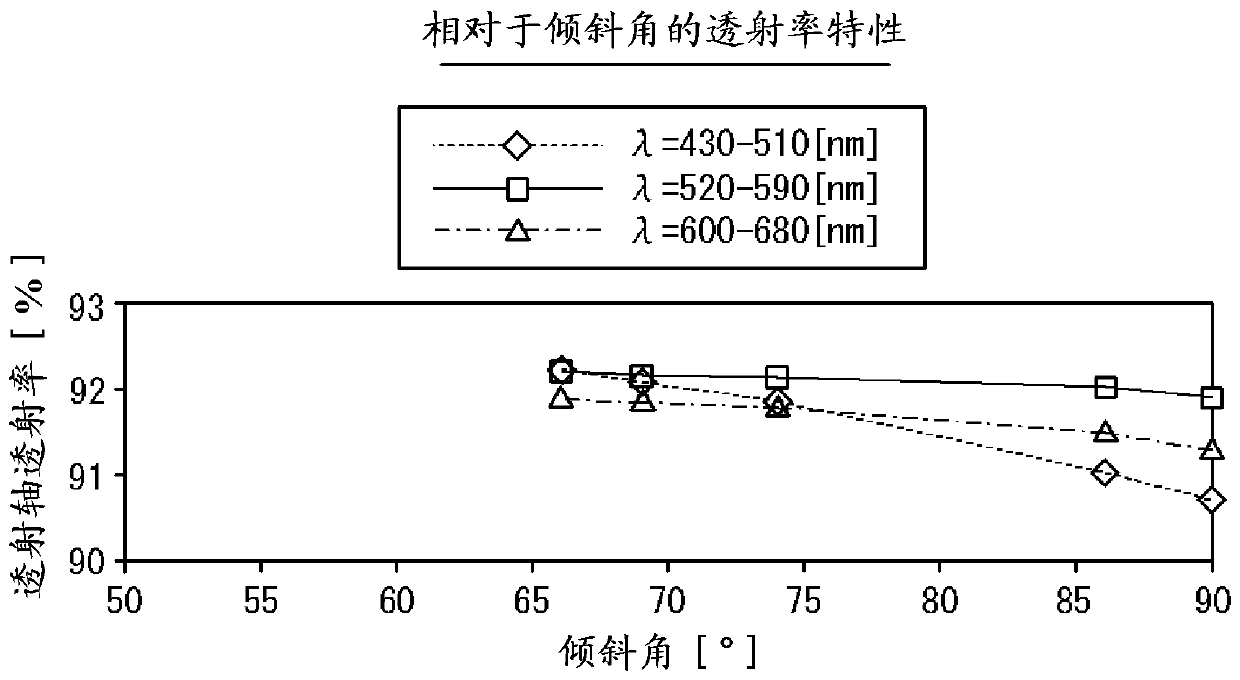

[0048] figure 1 It is a schematic cross-sectional view showing the polarizing element 1 according to one embodiment of the present invention. like figure 1As shown, the polarizing element 1 includes a transparent substrate 11 that is transparent to light in the wavelength band used; and a reflection layer that constitutes the lattice-shaped convex portions 10 arranged on one surface of the transparent substrate 11 at a pitch smaller than the wavelength of the light in the wavelength band used. 12. A dielectric layer 13 formed on the reflective layer 12 and an absorption layer 14 formed on the dielectric layer 13. That is, the polarizing element 1 has a one-dimensional grid-shaped wire grid in which the reflective layer 12 , the dielectric layer 13 and the absorption layer 14 are stacked in this order from the transparent substrate 11 side, and the grid-shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com