A kind of preparation method of alpha phase gallium oxide thin film

A phase gallium oxide thin film technology, which is applied in the field of preparation of alpha phase gallium oxide thin film, can solve the problem of low film formation rate and achieve the effect of uniform particle size distribution, smooth surface and large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

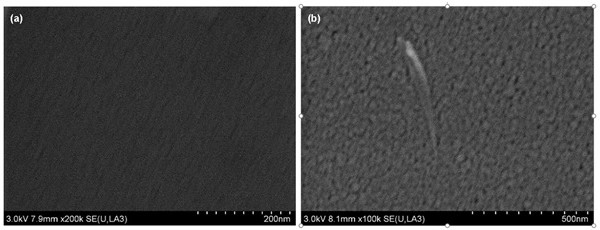

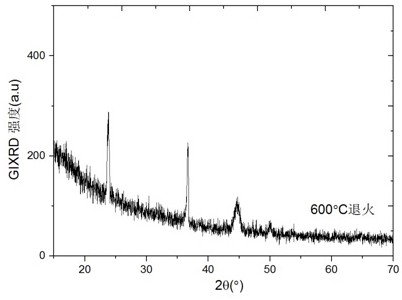

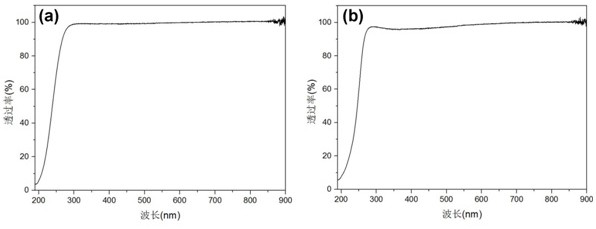

[0024] The preparation of the gallium oxide film in this embodiment adopts the magnetron sputtering method, and the m-plane sapphire substrate is ultrasonically cleaned in acetone, absolute ethanol and deionized water for 15 minutes, and then dried with nitrogen gas for use. The substrate and target were loaded into the vacuum chamber, the target was a high-purity gallium oxide ceramic target, and the distance between the target and the substrate was controlled at 6.5 cm. Before deposition, the vacuum chamber was first evacuated to make the vacuum degree reach 3×10-6 Pa, and then high-purity argon gas was introduced, the gas flow rate was 40 sccm, and the vacuum degree of the deposition chamber was maintained at 1 after standing for a period of time. pa; and pre-bombard the target for a period of time to clear the surface contamination. During the deposition process, the sputtering power was 40 W, the deposition temperature was 25 degrees Celsius, and the deposition time was c...

Embodiment 2

[0028] The preparation of the gallium oxide thin film in this embodiment adopts the magnetron sputtering method, and the m-plane sapphire substrate is ultrasonically cleaned in acetone, absolute ethanol and deionized water for 15 minutes, and then dried with nitrogen gas for use. The substrate and target were loaded into the vacuum chamber, the target was a high-purity gallium oxide ceramic target, and the distance between the target and the substrate was controlled at 6.5 cm. Before deposition, the vacuum chamber was first evacuated to make the vacuum degree reach 3 × 10-6 Pa, and then high-purity argon gas was introduced, and the gas flow was 40 sccm, and the vacuum degree of the deposition chamber was maintained at 1 after standing for a period of time. pa; and pre-bombard the target for a period of time to clear the surface contamination. During the deposition process, the sputtering power was 40 W, the deposition temperature was 25 degrees Celsius, and the deposition time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com