Conducting building block

A technology of building blocks and conductive plates, applied in entertainment, sports accessories, toys, etc., can solve the problems of high consumption of process materials, inability to faithfully present luminous patterns, loss of power conduction, etc., and achieve the effect of saving a lot of money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described below in conjunction with the accompanying drawings, in which similar reference numerals represent similar elements.

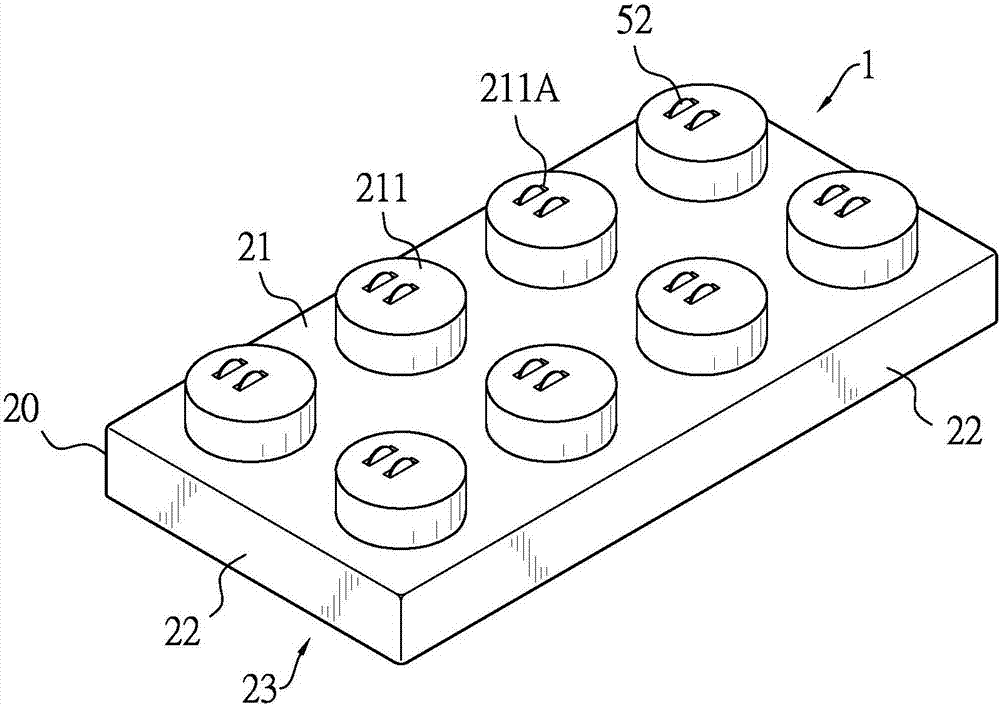

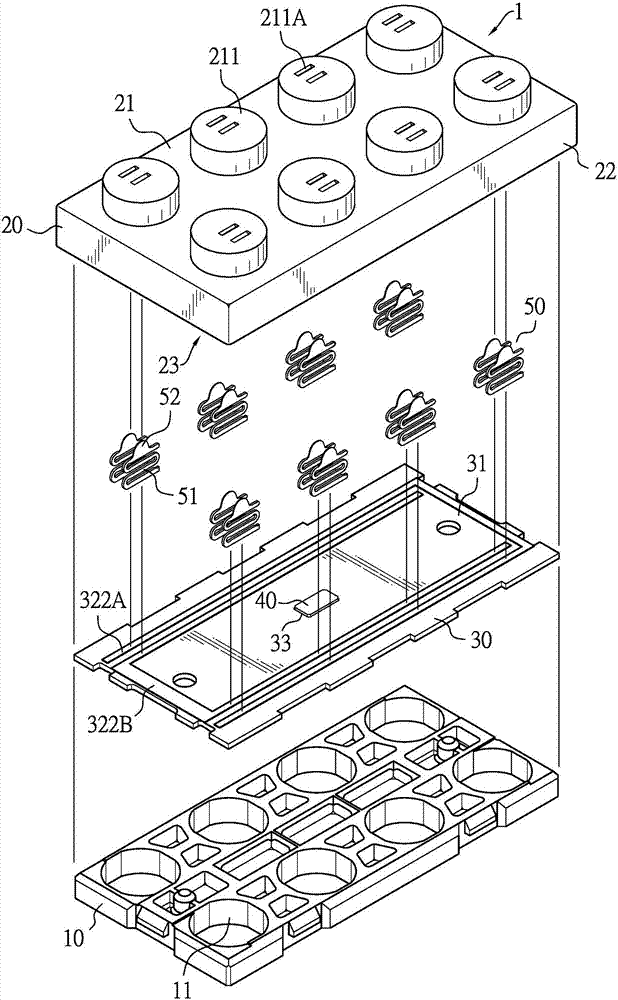

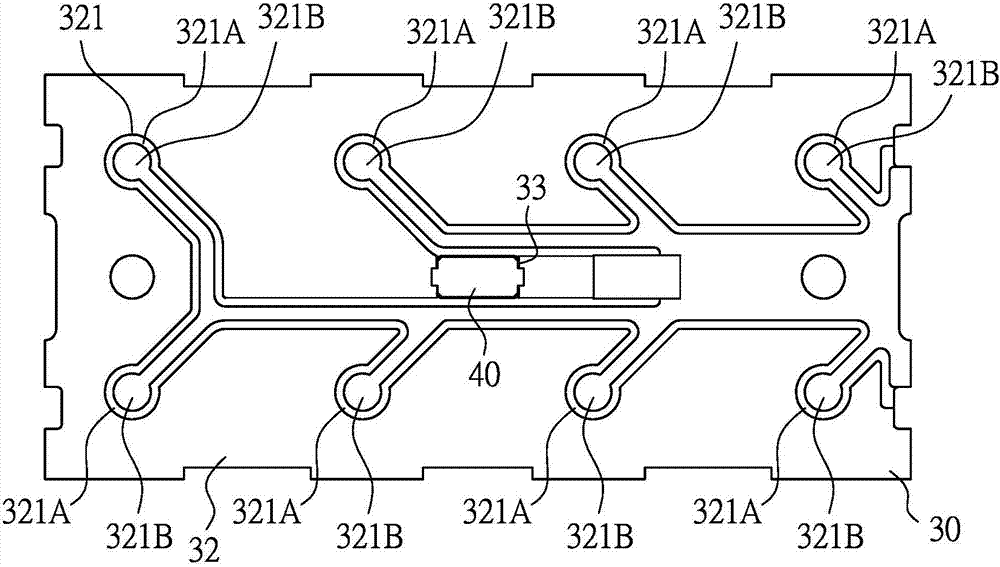

[0029] Such as figure 1 and figure 2 As shown, the conductive building block 1 of the present invention includes: a base 10 , a top cover 20 , a conductive plate 30 , a light emitting diode 40 and a plurality of electrical connectors 50 . The base 10 is a rectangular faceplate structure, and eight wedge holes 11 are pierced on the base 10 , the eight wedge holes 11 are respectively arranged in two parallel rows, and each row has four wedge holes 11 .

[0030] The top cover 20 is a hollow light-transmitting cover body, which has a top 21 and four ring side parts 22, and forms an accommodating space 23 inside the top cover 20 surrounded by the top 21 and the four ring side parts 22, And the accommodating space 23 is further provided with the aforementioned base 10 . The base 10 is installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com