A method of using construction waste to prepare recycled aggregate

A technology of recycled aggregate and construction waste, which is applied in the direction of construction waste recycling, recycling technology, and furniture waste recycling. Insufficient effect and other problems, to achieve the effect of reducing grinding effect, reducing heat transfer, and reducing insufficient contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

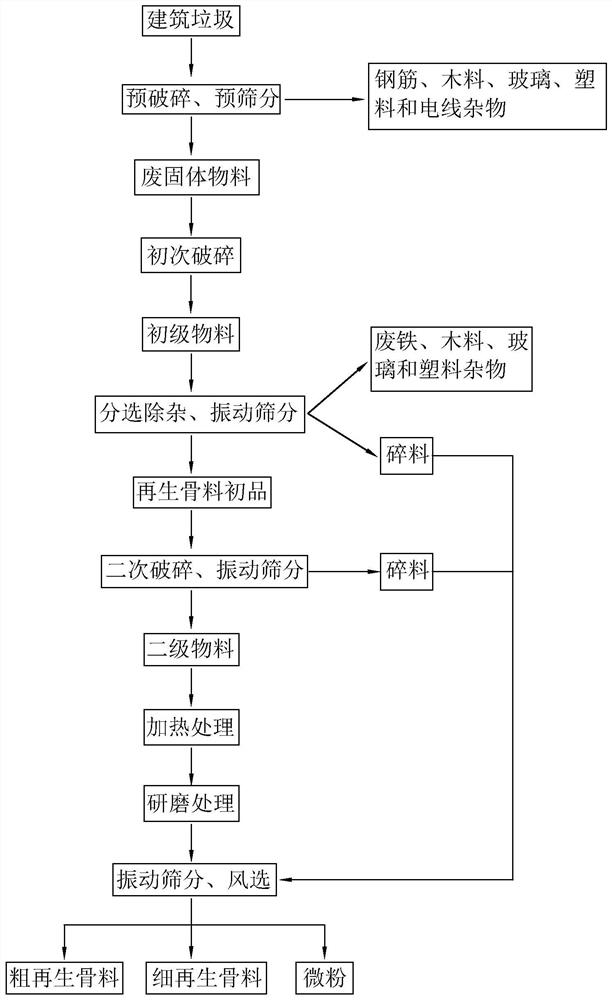

[0042]refer to figure 1 , is a kind of method that utilizes construction waste to prepare recycled aggregate disclosed by the present invention, comprises the following steps:

[0043] S1: Pre-shredding and pre-screening the construction waste generated by the demolition of an abandoned factory to remove steel bars, wood, glass, plastics and wires to obtain waste solid materials with a particle size of less than 200mm.

[0044] Specifically, the pre-crushing and pre-screening in step S1 are all carried out manually, mainly by hammering, cutting and sorting to remove steel bars, wood, glass, plastics and wires to obtain particles with a particle size of less than 200 mm. The waste solid materials are transported to the crusher by plate chain conveyor.

[0045] S2: Use a crusher to crush waste solid materials for the first time to obtain primary materials with a particle size below 40mm;

[0046] Specifically, the crusher used in step S2 is a jaw crusher.

[0047] S3: Sorting...

Embodiment 2

[0058] refer to figure 1 , is a method for preparing recycled aggregates from construction waste disclosed in the present invention. The difference between this embodiment and Embodiment 1 is that the processing process of step S5 is different from that of step S6. details as follows:

[0059] S5: Put the secondary material obtained in step S4 into the airtight container, and keep the volume ratio of the volume of the secondary material and the airtight container at 0.5:1, that is, the filling factor of the secondary material is 0.5; drive the airtight container at 45n Rotate at a speed of 1 / min, and pass in water vapor mixed with acetic acid molecules through the steam valve of the airtight container. Specifically, the amount of acetic acid molecules in the water vapor accounts for 5%; until the temperature in the airtight container reaches 200°C , Atmospheric pressure reaches 1.5MPa, stop feeding water vapor, close the steam valve, after the pressure is constant, keep const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com