Method and device for improving opening degree control precision of finish rolling side guide plate

A technology for controlling precision and side guides, which is applied in rolling mill control devices, guiding/positioning/alignment devices, metal rolling, etc., and can solve problems affecting the accuracy of the opening of the side guides, not being on a straight line, and the amount of frames generated by the side guides, etc. problems, to achieve the effects of improving stability, reducing flicking and crushing, and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

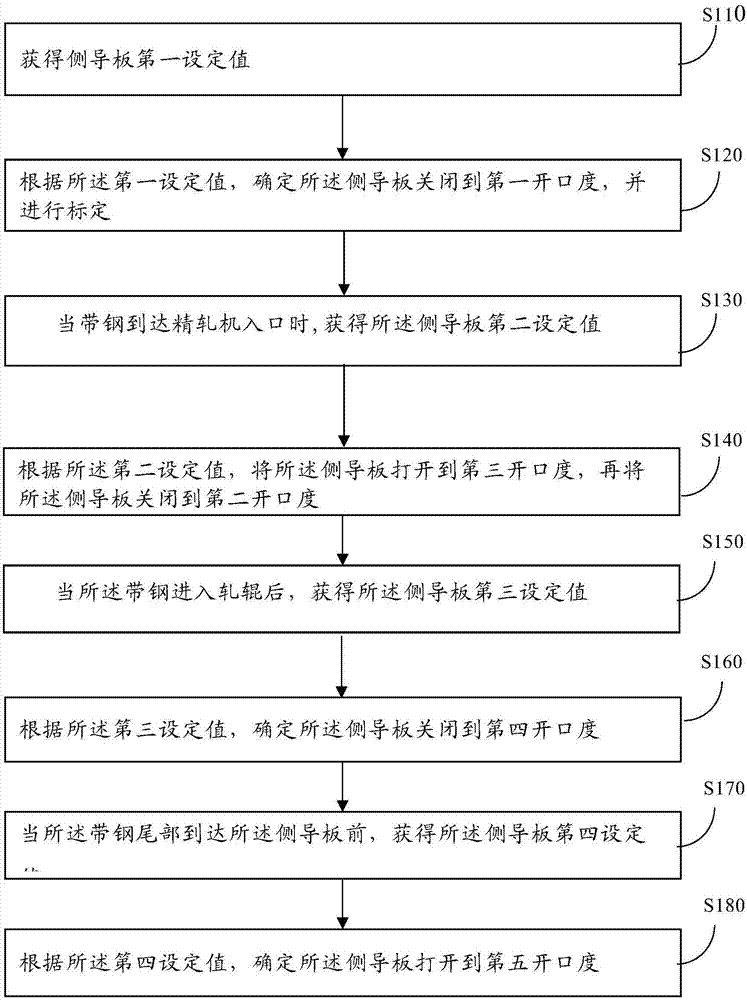

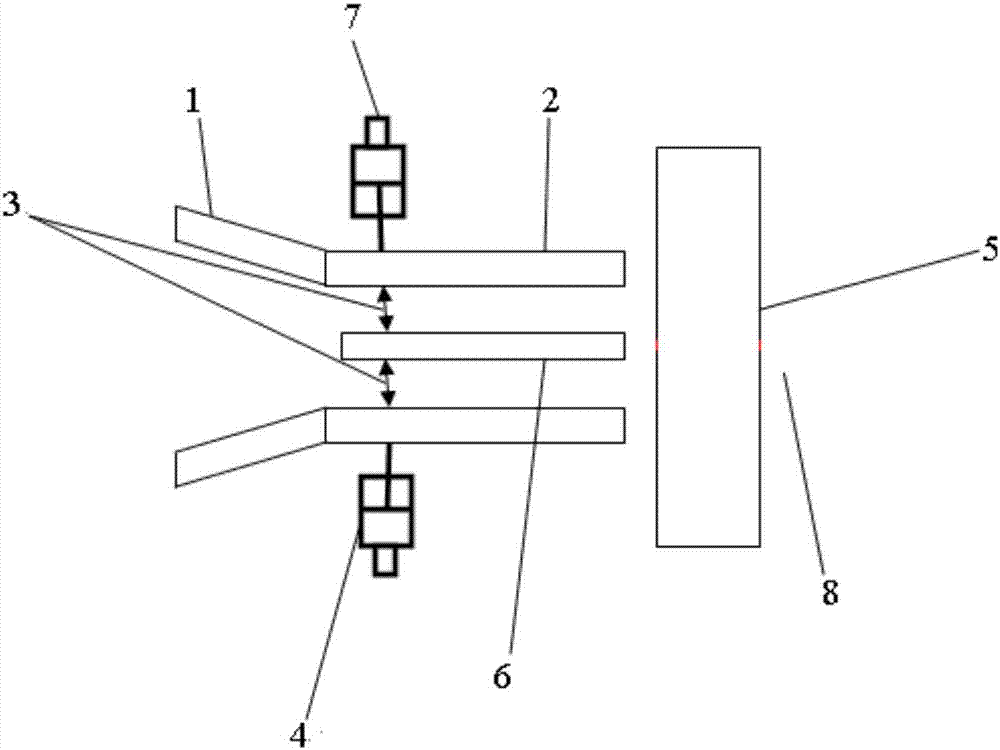

[0027] A method for improving the control accuracy of the opening degree of the side guide plate of the finishing rolling provided by the embodiment of the present application includes referring to figure 1 , image 3 :

[0028] Step 110: Obtain the first set value of the side guide plate 1;

[0029] Specifically, the first set value is the value set for the side guide plate 1 in the primary monitoring interface, wherein the first set value can be set according to the range of the opening degree 2 of the side guide plate Certainly. When the opening degree 2 of the side guide plate ranges from 850mm to 2350mm, the first set value can be any value within the opening degree range of the side guide plate.

[0030] Step 120: According to the first set value, determine that the side guide plate 1 is closed to the first opening degree, and perform calibration;

[0031] Specifically, the first opening degree is the opening degree of the side guide plate under the premise that the ...

Embodiment 2

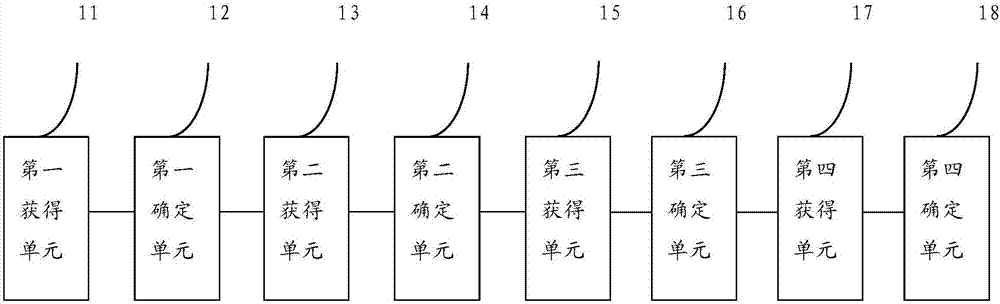

[0048] Such as figure 2 As shown, in order to better solve the technical problems faced by the present application, the embodiment of the present application also provides a device for improving the control accuracy of the opening degree of the finish rolling side guide plate, the device comprising:

[0049] A first obtaining unit 11, the first obtaining unit 11 is used to obtain the first set value of the side guide plate;

[0050] A first determining unit 12, the first determining unit 12 is configured to determine that the side guide plate is closed to a first opening degree according to the first set value, and perform calibration;

[0051] When the strip reaches the entrance of the finishing mill,

[0052] A second obtaining unit 13, the second obtaining unit 13 is configured to obtain a second set value of the side guide plate;

[0053] A second determination unit 14, the second determination unit 14 is configured to open the side guide plate to a third opening degree...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Opening | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com