Rapid clamp

A fast, fixture technology, used in clamping, manufacturing tools, supports, etc., can solve the problems of inability to adapt to the plane processing of large-scale thin plates with holes, complicated and time-consuming clamping of large-scale thin plates with holes, and difficult to achieve fast and high-precision clamping and other problems , to achieve the effect of fast adaptive clamping, easy disassembly and replacement, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

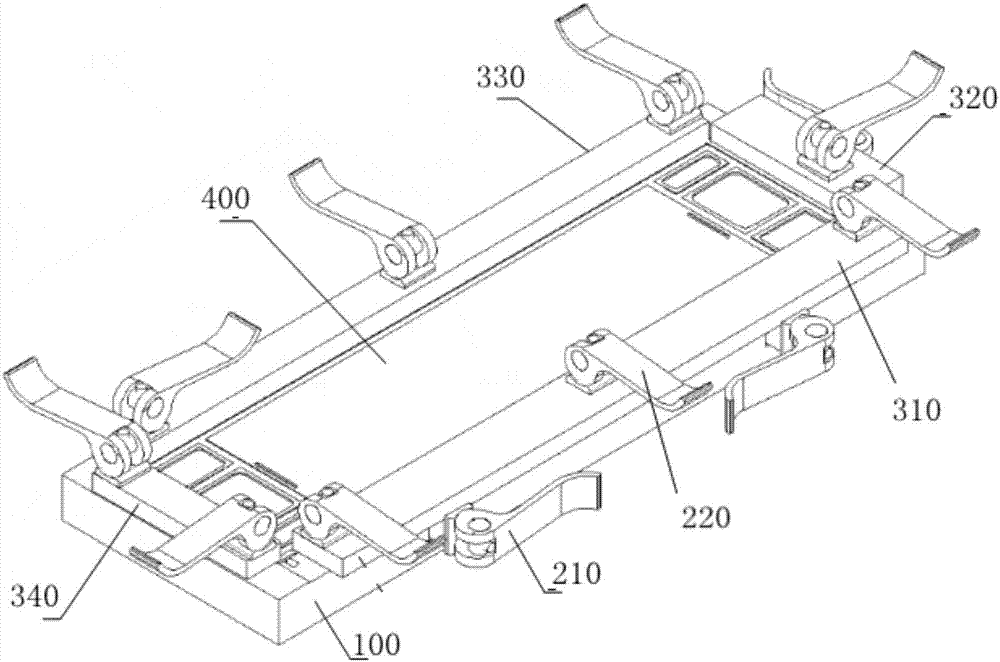

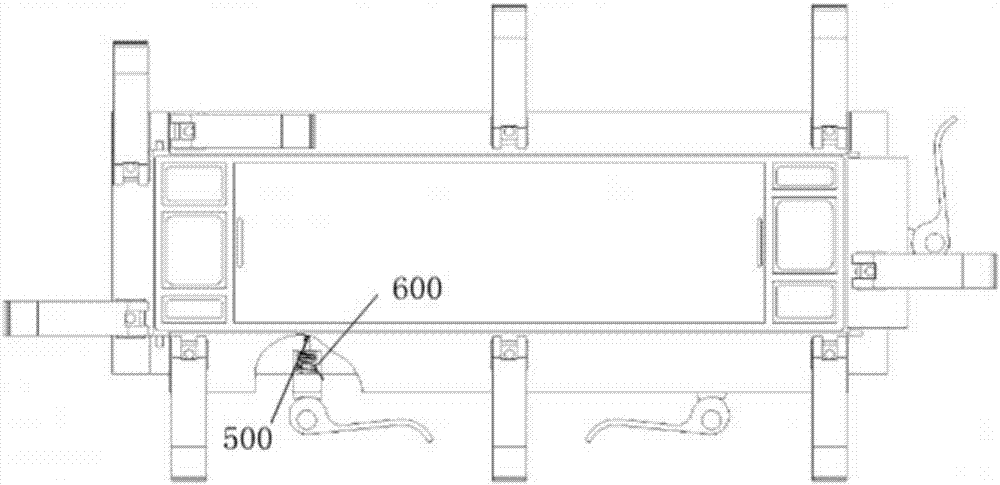

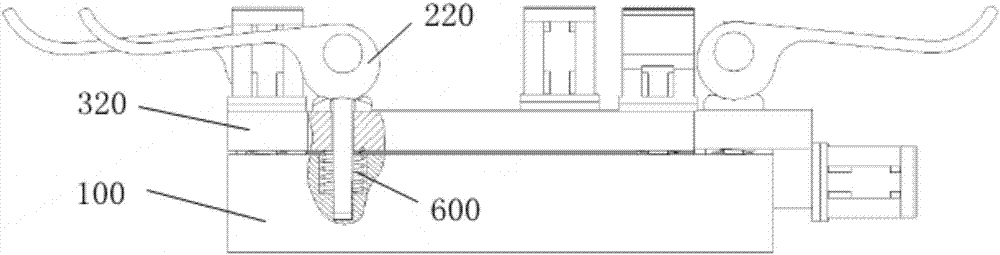

[0040] Please also refer to Figure 1-3 , the present embodiment provides a quick clamp, including a reference base 100, a pressing plate assembly and a quick locking assembly.

[0041] Among them, such as Figure 5 As shown, the reference base 100 is preferably made of a rigid material (such as marble, metal, etc.), and the upper surface of the reference base 100 has a positioning reference surface for setting the clamping position of the workpiece 400 to be clamped. Preferably, a plurality of grooves of the first type are provided on the upper surface of the reference base 100 for taking out the workpiece 400 to be clamped from the reference base 100 . Preferably, the datum surface, the side surface and the bottom surface of the datum base 100 are finished with a flatness of less than 0.01mm and a verticality tolerance of less than 0.005mm. Both the datum boss and the datum surface of the datum base 100 are processed with a counterbore, and the bottom surface of the counte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com