Membrane wrapping control-releasing fertilizer continuous production method and apparatus

A technology of coated controlled-release fertilizer and production method, which is applied in the direction of fertilization device, fertilizer mixture, application, etc., can solve the problems of complex operation, failure to realize continuous production of coated controlled-release fertilizer, cumbersome steps, etc., and achieve simple operation , reduce energy consumption and avoid cumbersome operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

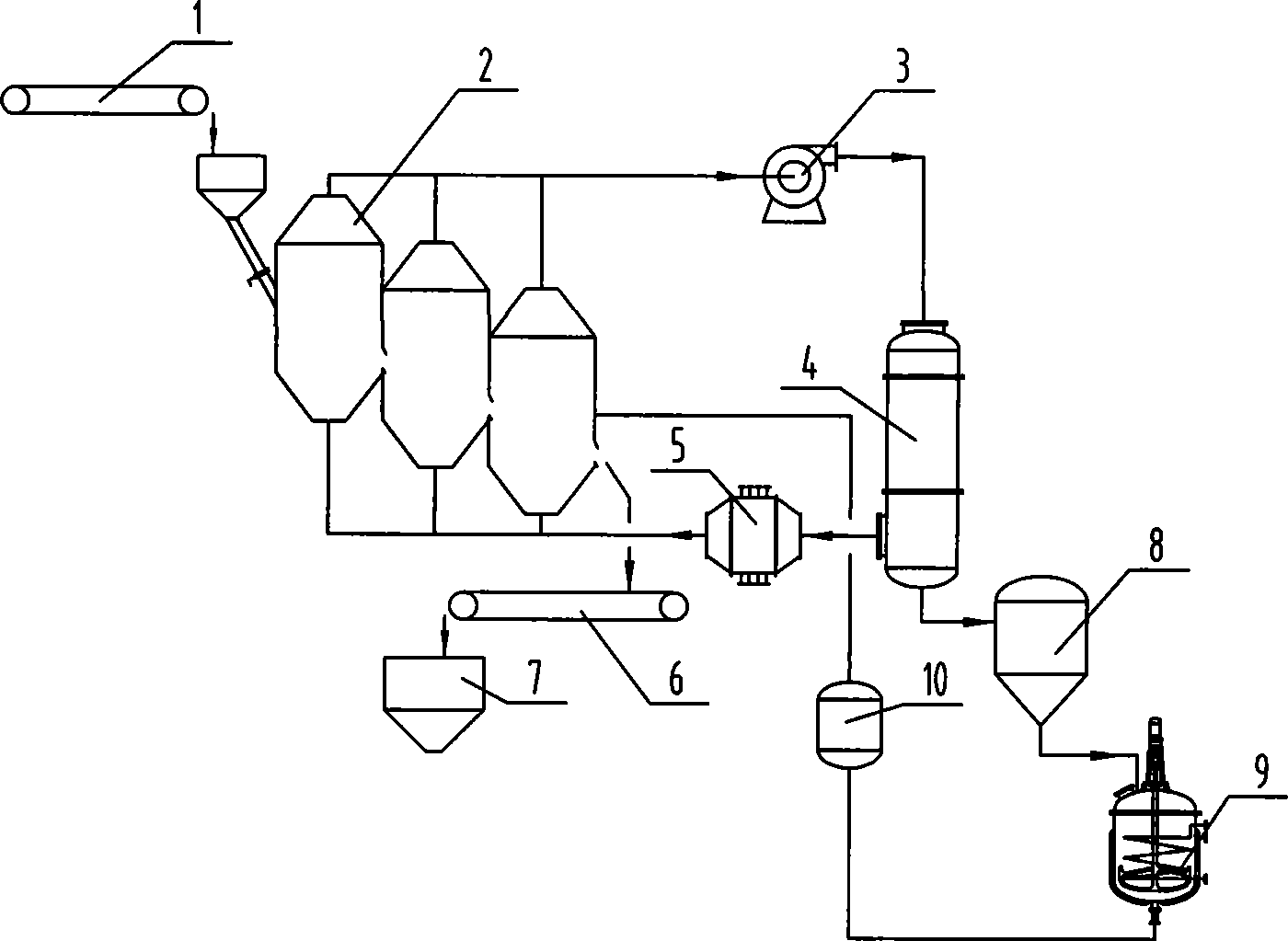

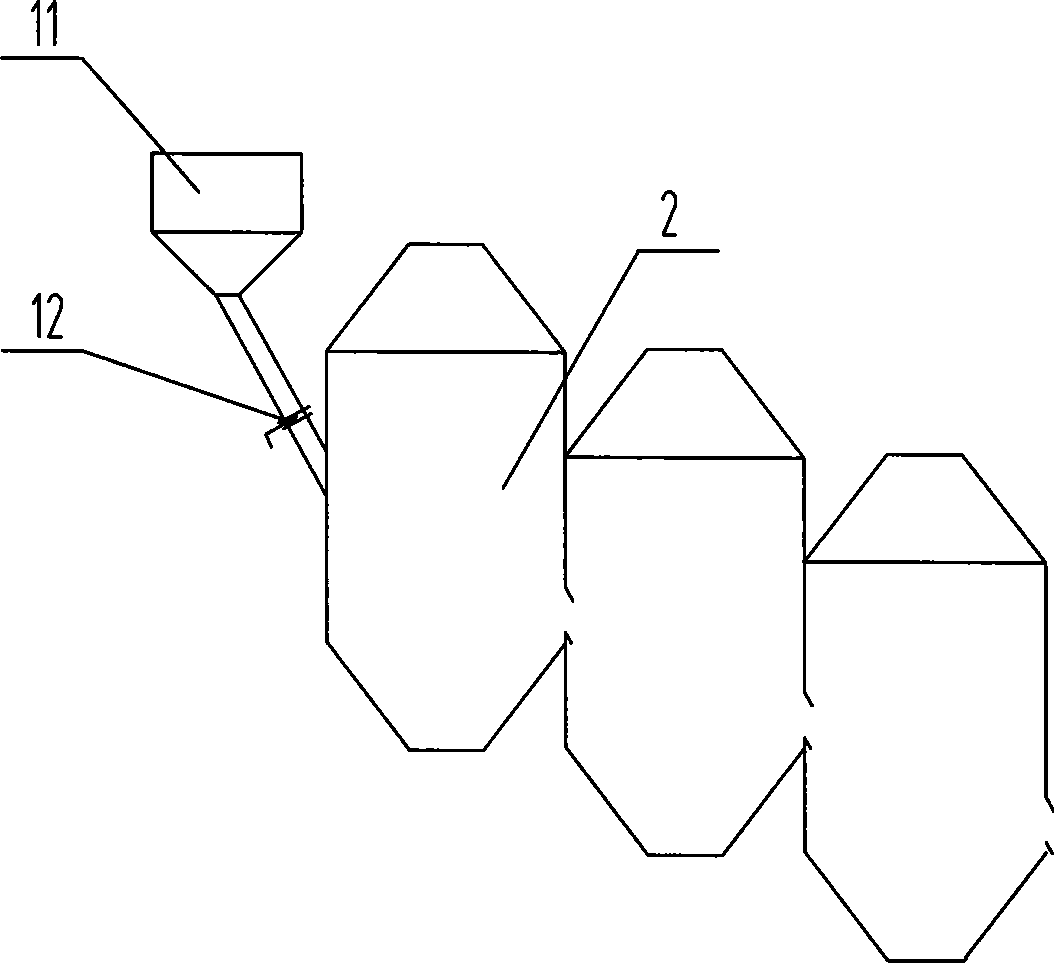

[0020] The device of the present invention realizes the continuous production method of coated controlled-release fertilizer, the structure is as follows figure 1 , 2 As shown, it includes quantitative feeder 1, continuous film-coated fluidized bed 2, induced draft fan 3, condenser 4, heater 5, conveyor belt 6, finished product bin 7, solvent recovery tank 8, dissolution tank 9 and spray liquid The storage tank 10; the specific connection method is: the quantitative feeder 1 is connected to the feeding bin 11 of the continuous coating continuous type 2, the air outlet of the continuous coating fluidized bed 2 is connected to the induced draft fan 3 through the air duct, and the induced draft fan 3 passes through The air pipe is connected to the condenser 4, the condenser 4 is connected to the heater 5 through the air pipe, the heater 5 is connected to the air inlet of the continuous coated fluidized bed 2 through the air pipe, and the discharge port of the continuous coated fl...

Embodiment 2

[0023] The device of the present invention realizes the continuous production method of coated controlled-release fertilizer, and the structure is still as follows figure 1 , 2 As shown, the difference is that the upstream coating tower has a volume of 2.0m 3 feeding bin. Dissolving kettle 9 is all 7m by volume 3 It consists of 3 dissolution tanks connected in parallel.

Embodiment 3

[0025] The device of the present invention realizes the continuous production method of coated controlled-release fertilizer, and the structure is still as follows figure 1 , 2 As shown, the difference is that the upstream coating tower has a volume of 2.5m 3 feeding bin. Dissolving kettle 9 is all 9m by volume 3 5 dissolution tanks are connected in parallel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com