Mechanical arm system with conveying function

A technology of robotic arms and functions, applied in the field of robotic arms, to achieve the effect of easy grasping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

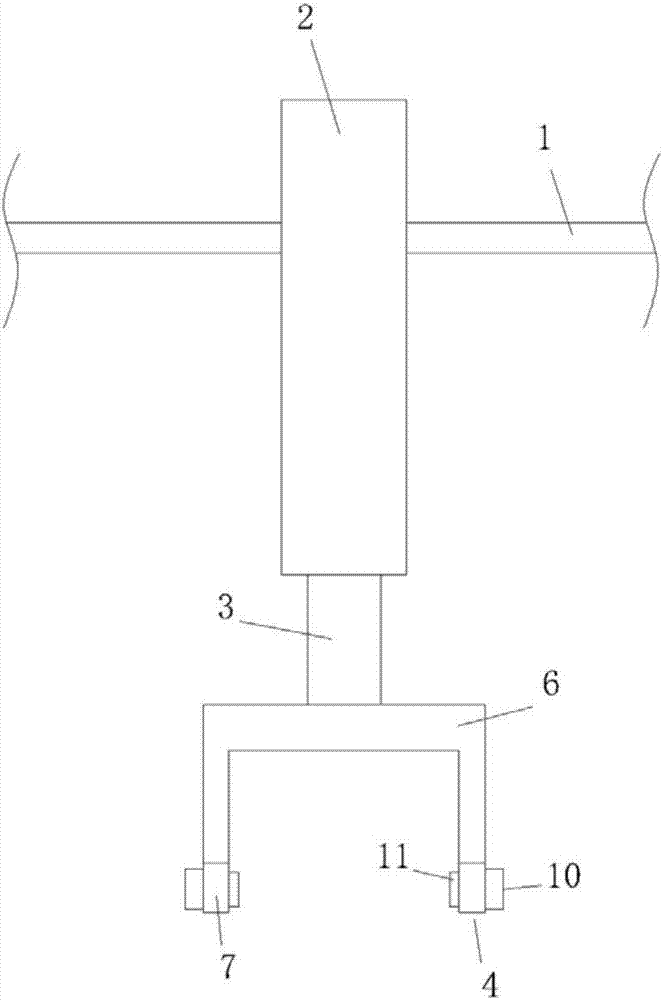

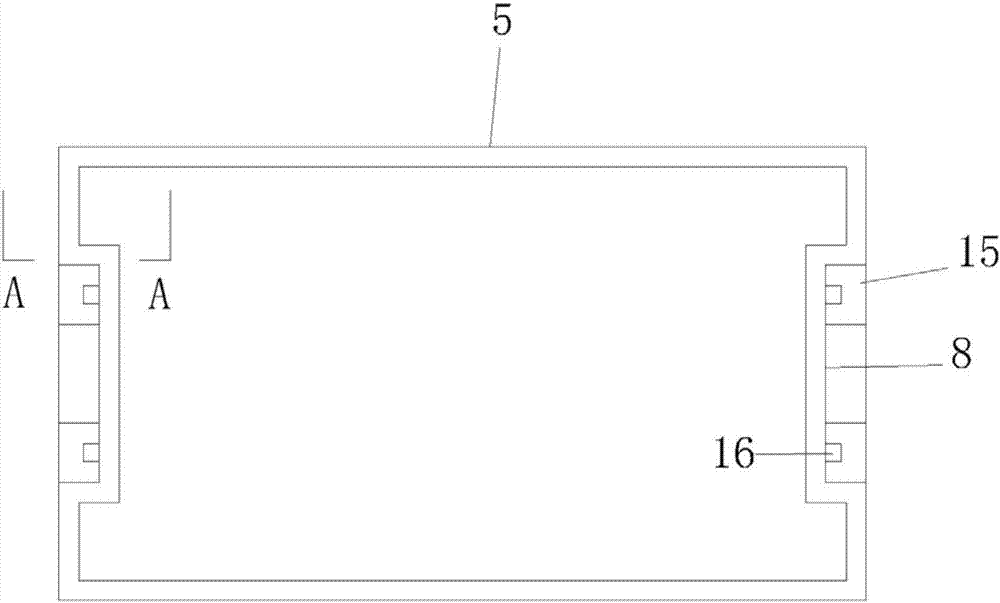

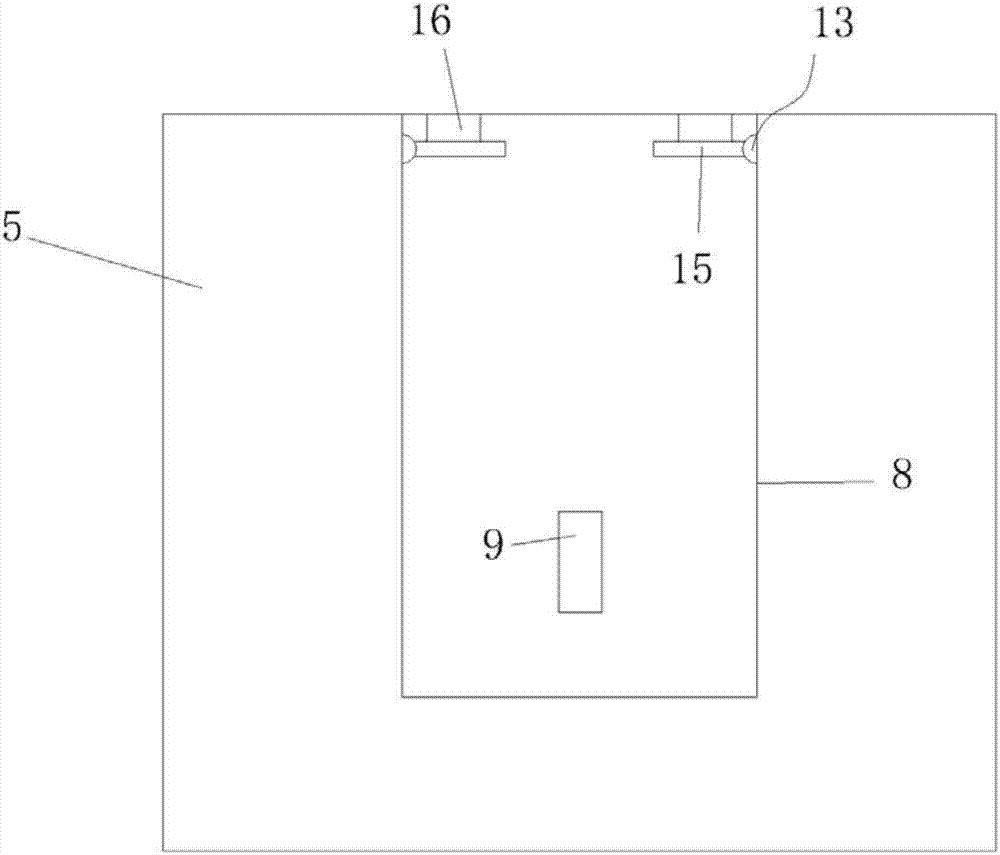

[0015] The mechanical arm system with conveying function as shown in the accompanying drawings is characterized in that it includes a horizontally arranged slide rail 1, a sliding end 2 cooperating with the slide rail 1, and a telescopic lifting part 3 arranged in the sliding end 2 , the grabbing part 4 arranged at the end of the lifting part 3 and the storage box 5 for grabbing by the grabbing part 4, the bottom of the lifting part 3 is provided with an extension rod 6 with a corner, and the grabbing part 4 is arranged at the end of the extension rod 6, And the grasping part 4 is provided with a stretchable grasping device for grasping the storage box 5 .

[0016] When in use, slide the sliding end 2 horizontally to a suitable position to lower the lifting part 3 so that the grabbing part 4 grabs the storage box 5. When the grabbing device grabs the storage box 5, the lifting part 3 shrinks upwards and slides end 2, and slide with the sliding end 2 to transport the glove box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com