Calender for preparation of floor films

A technology of calender and floor film, applied in the field of calender, can solve the problems of reducing work efficiency, blocking the rotation of pressing rollers, unqualified floor film, etc., and achieves the effect of improving efficiency and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

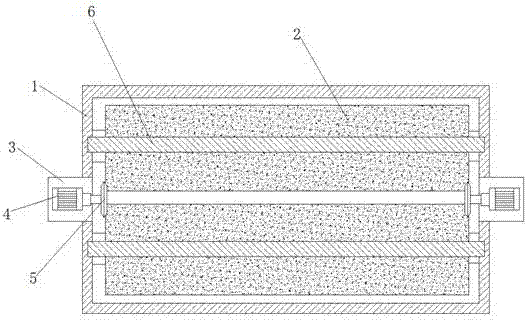

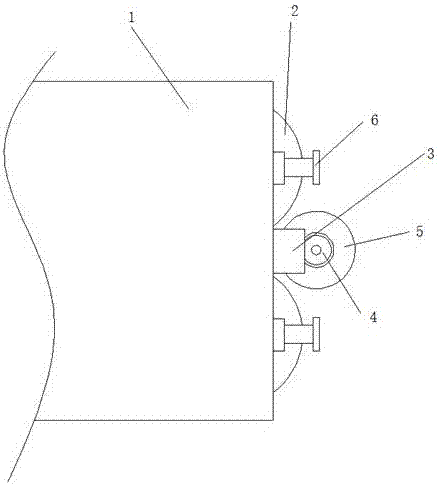

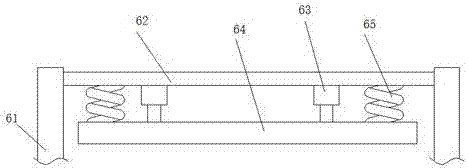

[0017] refer to Figure 1-3 , a calender for preparing a floor film, comprising a calender feed port 1, a waste collection box is arranged below the calender feed port 1, and two sets of parallel pressure rollers 2 are installed in the calender feed port 1 through a rotating shaft , the two ends of the two groups of pressure rollers 2 are provided with a spacing adjustment device, there is a calendering gap between the two groups of pressure rollers 2, and a mounting plate 3 is arranged on the side wall of the calender inlet 1 at both ends of the calendering gap, and the installation A drive motor 4 is installed on the plate 3, the output shaft of the drive motor 4 i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap