Automatic laminating machine and packaging film

A technology of packaging film and laminating machine, applied in lamination devices, lamination, layered products, etc., can solve the problem of inability to isolate static electricity, etc., and achieve the effect of efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

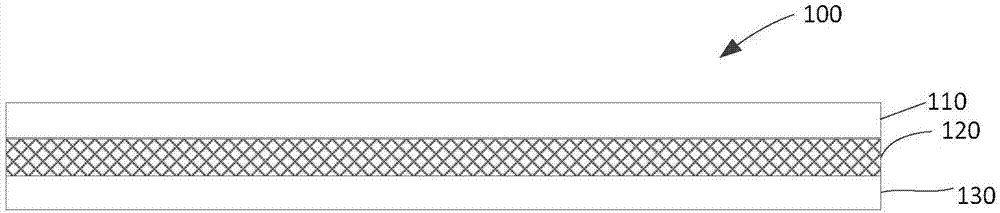

[0021] Such as figure 1 As shown, the present invention provides a packaging film 100, comprising a first adhesive film layer 110, a wire mesh layer 120 and a second adhesive film layer 130 arranged in sequence from top to bottom, the first adhesive film layer 110 and The second adhesive film layer 130 is pasted and connected through the adhesive coated on the wire mesh layer 120 . The materials of the first film layer 110 and the second film layer 130 include polyvinylidene chloride, polyethylene naphthalate, polypropylene, polyethylene and polyethylene terephthalate one or more of.

[0022] The packaging film 100 in the embodiment of the present invention can shield static electricity through the wire mesh layer 120 to protect packaged electronic products from electrostatic interference.

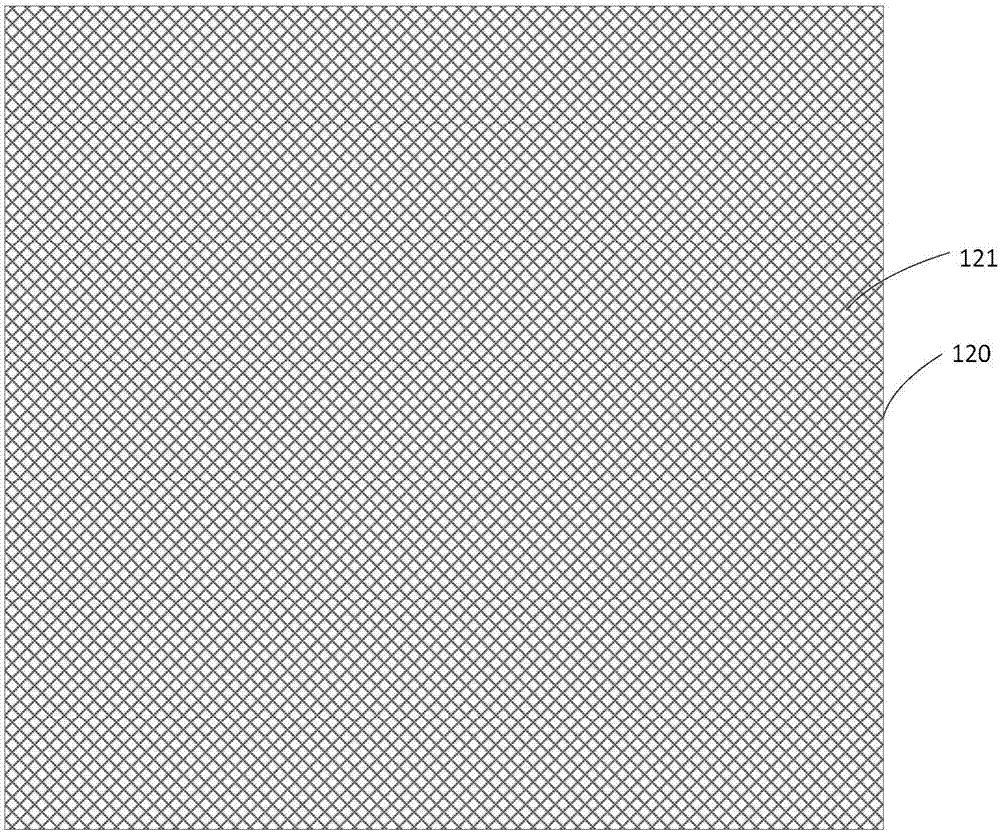

[0023] Such as figure 2 As shown, the metal wires 121 in the wire mesh layer 120 are arranged in a cross. For example, the wires 121 in the wire mesh layer 120 form an angle of 45 deg...

Embodiment 2

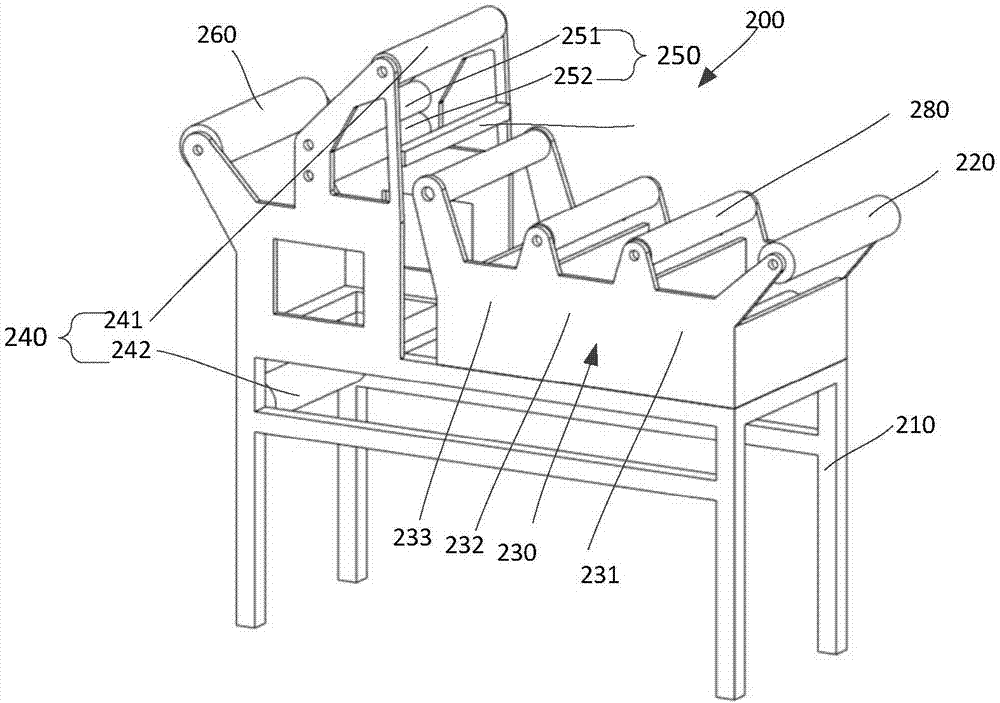

[0026] Such as image 3 As shown, the present invention also provides an automatic laminating machine 200 of the above-mentioned packaging film 100 on the other hand, including a frame 210, a wire mesh roller 220, a cleaning tank 230, an adhesive film roller 240, a laminating roller 250 and a splicing roller 250. The material roller 260, the wire mesh roller 220, the adhesive film roller 240, the bonding roller 250, and the receiving roller 160 are rotatably connected to the frame 210, and the cleaning pool 230 is fixed to the frame 210; The discharge end of the wire mesh roller 220 corresponds to the feed end of the cleaning tank 230, the discharge end of the cleaning tank 230 corresponds to the feed end of the laminating roller 250, and the adhesive film roller The discharge end of 240 corresponds to the feed end of the bonding roller 250 , and the discharge end of the bonding roller 250 corresponds to the feed end of the receiving roller 260 .

[0027] The automatic lamina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com