A road construction method to solve the problem of hollowing out at the bottom of pavement slabs

A technology for road construction and road slabs, applied in roads, roads, road repairs, etc., can solve problems such as voids, low support strength of soil base, road surface fracture and collapse, and achieve the effect of avoiding voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

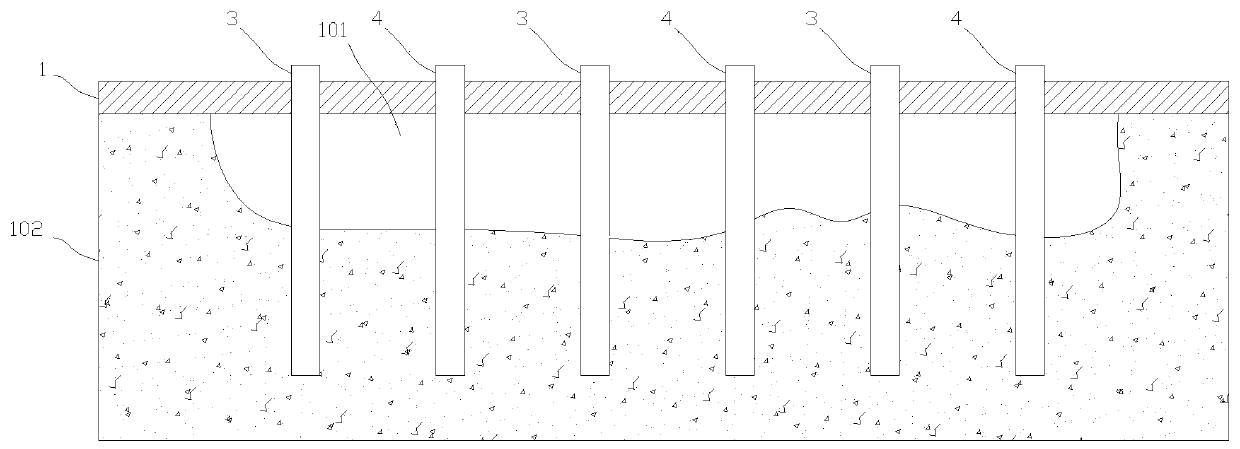

[0025] Depend on figure 1 , figure 2 , image 3 , Figure 4 Shown, the road construction method that solves the empty problem at the bottom of the road slab of the present embodiment, it comprises the following steps:

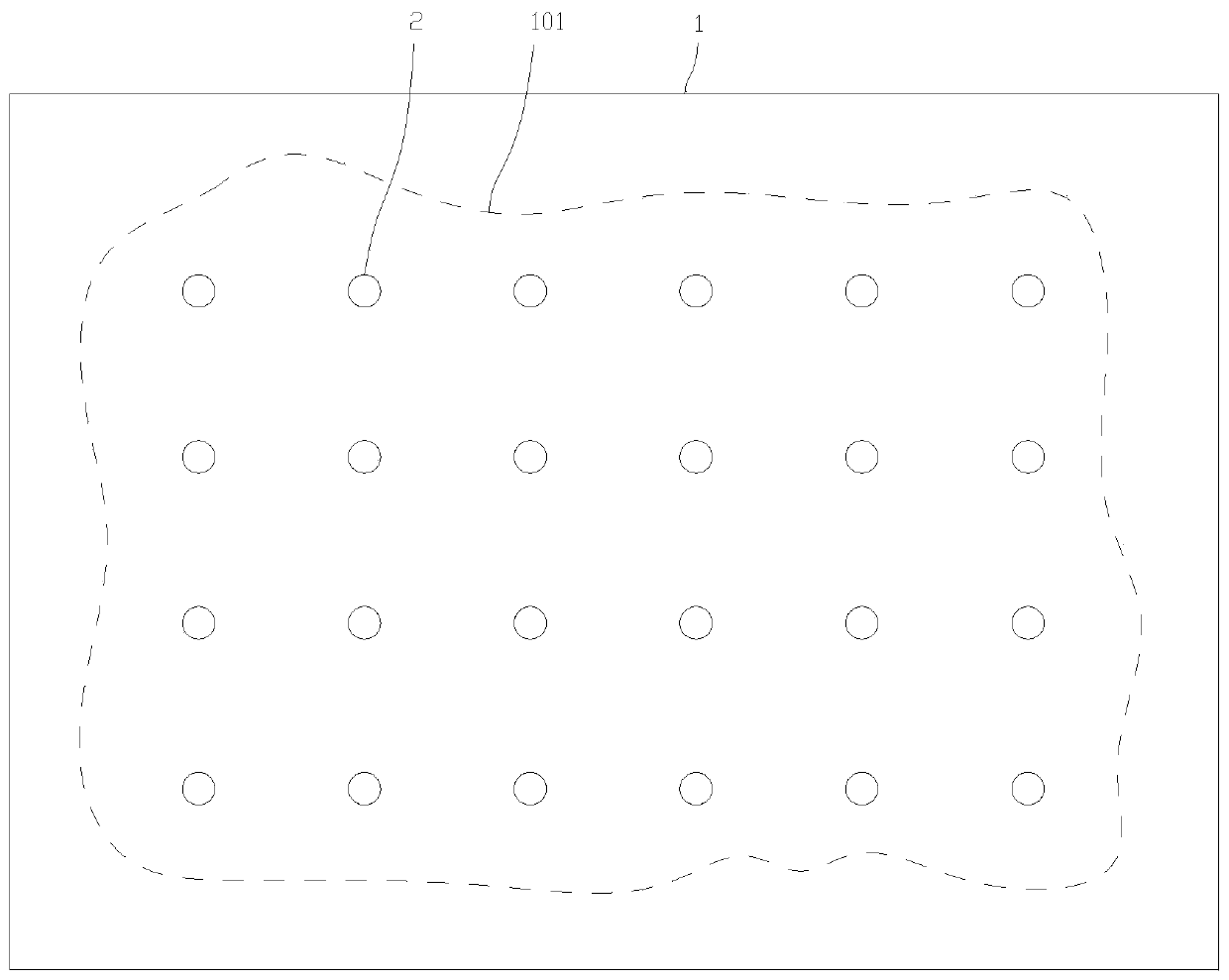

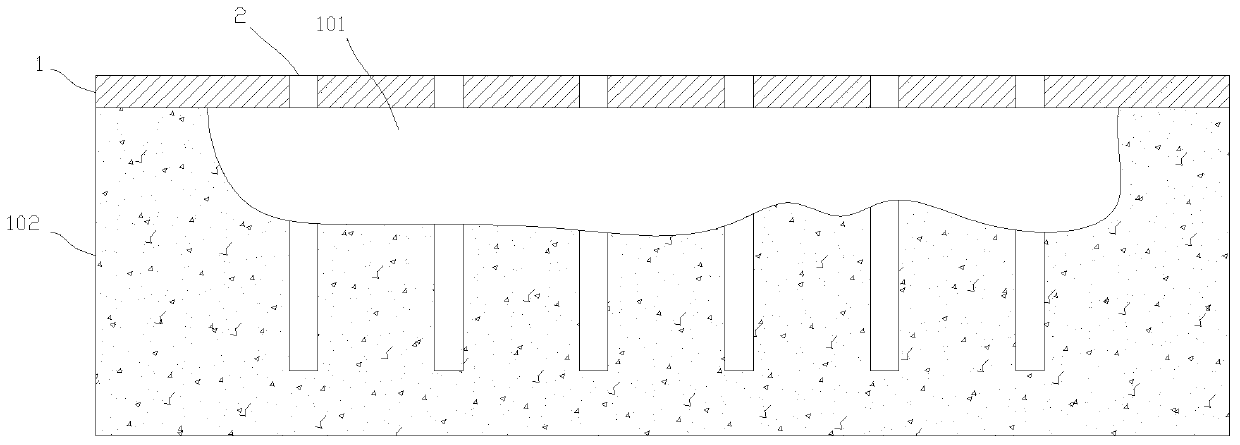

[0026] (1), measure void area 101 on road surface 1 with ground penetrating radar;

[0027] (2), vertically drill a hole on the empty area 101, the drill bit starts drilling from the road surface above the empty area, after the drill bit breaks through the road surface, it continues to move vertically downward, and then the drill bit drills into the soil below the empty area 101 In the base layer 102, the drill bit should penetrate 1.2m into the soil base layer 102 below the void area 101, and the drill holes 2 are distributed in an array. The array area of the drill hole positions should be located in the void ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com