Construction method of decorative sheet dry hanging system, and decorative sheet dry handing system

A construction method and technology for decorative panels, applied in the direction of walls, covering/lining, construction, etc., can solve problems such as difficulty in installing decorative panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

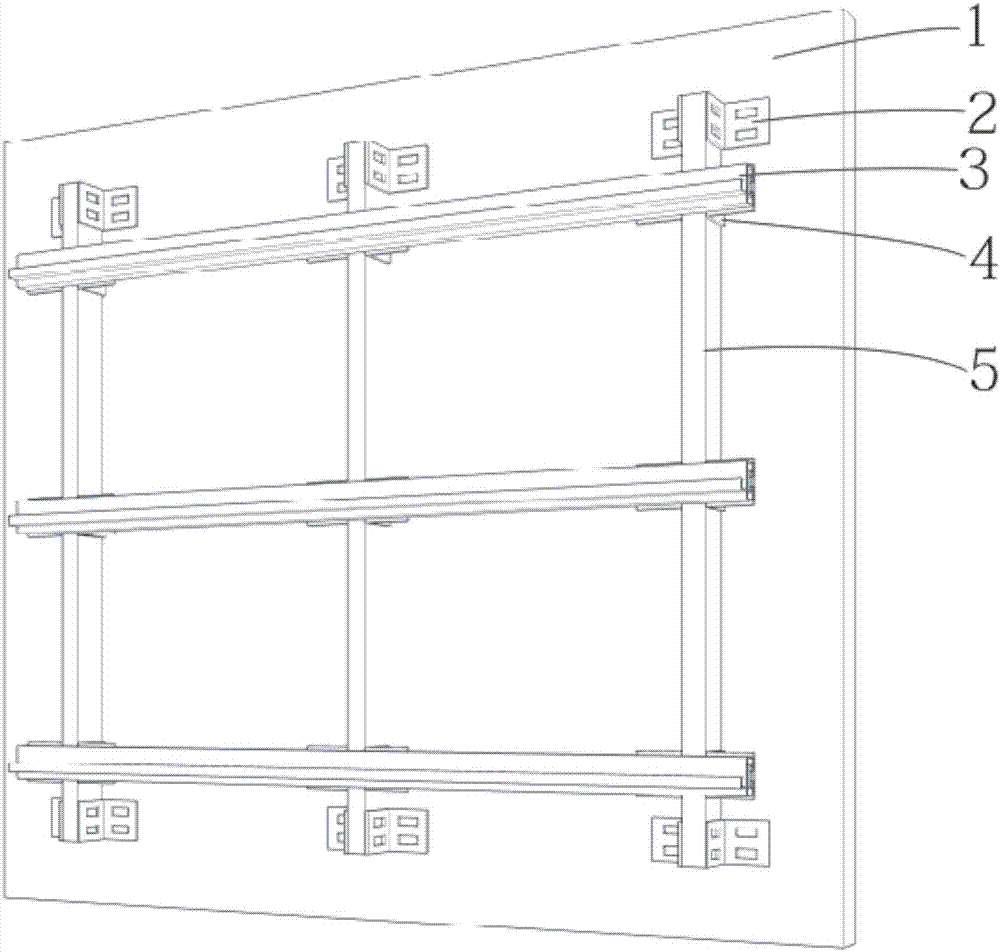

[0034] refer to figure 1 , figure 2 , Figure 6 to Figure 9 , a construction method of a decorative board dry-hanging system provided by the invention, comprising the following steps:

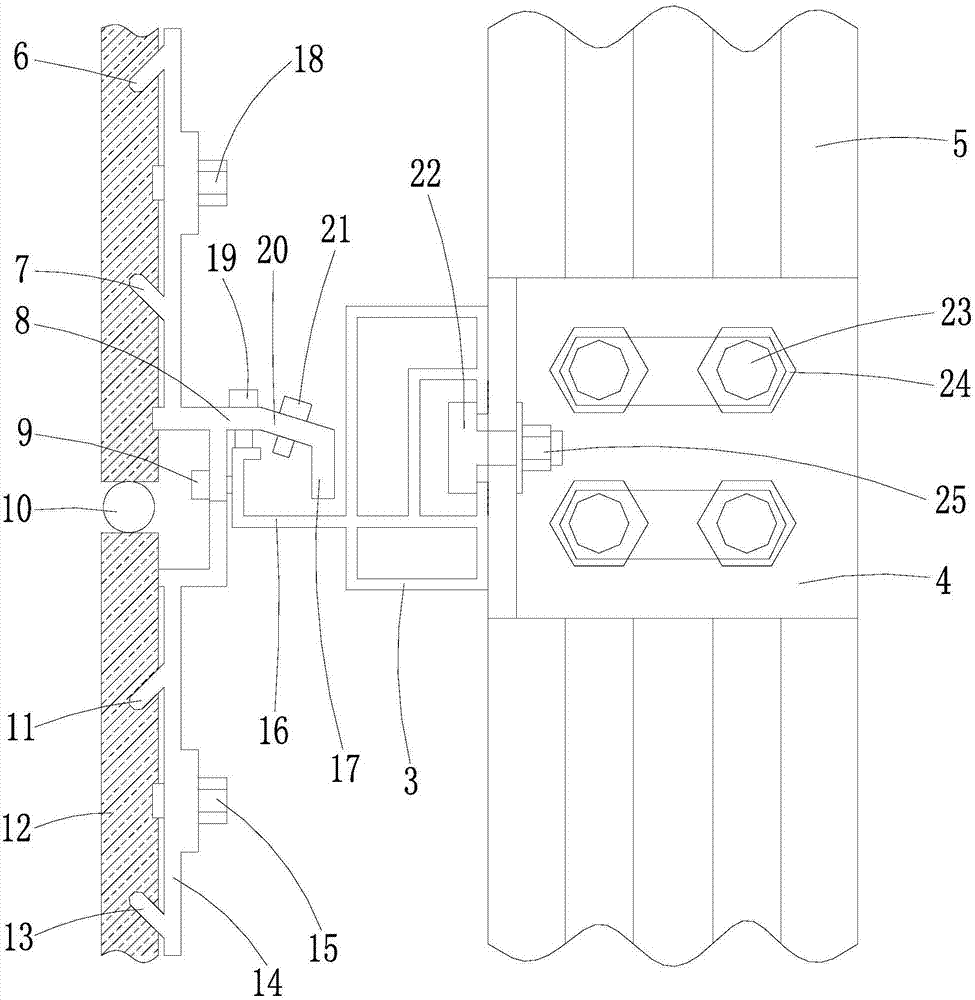

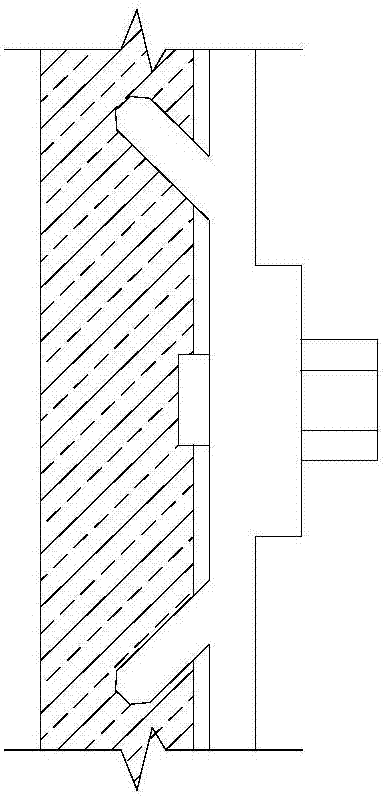

[0035] Step A: Install the pendant on the decorative board 12, the first chute, the second chute, the third chute and the fourth chute cut from top to bottom on the back of the decoration board 12, the first chute, the second chute The chute, the third chute and the fourth chute all extend to the side of the decorative panel 12, and according to the installation and arrangement direction of the decorative panel 12, the first force on the pendant matched with the first chute and the second chute The oblique hook 11 and the second stressed oblique hook 13 are respectively embedded in the first oblique groove and the second oblique groove along the sides of the decorative plate 12 to form an upper supporting point, and connect the pendant with the third oblique groove and the fourth oblique gro...

Embodiment 2

[0048] refer to figure 1 , figure 2 , image 3 , Figure 6 to Figure 9 ,, the difference with Embodiment 1 is:

[0049]The opening of the first chute is inclined downward, the opening of the second chute is upwardly inclined, the opening of the third chute is downwardly inclined, and the opening of the fourth chute is upwardly inclined. The upper part behind the positioning bracket 14 is provided with a through positioning bracket The first jacking bolt of the frame 14, the lower part behind the positioning bracket 14 is provided with the second jacking bolt that runs through the positioning bracket 14; the upper fastening device is the first jacking bolt 15, and the lower fastening device is the second jacking bolt. Tighten bolt 18. By tightening the first tightening bolt 15 and the second tightening bolt 18 , the hanger is tightly connected to the decorative panel 12 .

Embodiment 3

[0051] refer to figure 1 , figure 2 , Figure 4 , Figure 6 to Figure 9 , the difference from Example 1 is:

[0052] The opening of the first chute is upwardly inclined, the opening of the second chute is downwardly inclined, the opening of the third chute is upwardly inclined, and the opening of the fourth chute is downwardly inclined. The back of the positioning bracket 14 top is provided with a first rectangular The front end surface of the upper part of the positioning bracket 14 is provided with a first rectangular groove that matches the first rectangular protrusion, and the first rectangular protrusion is provided with a first locking bolt that runs through the first rectangular protrusion up and down. , the back of the positioning bracket 14 bottom is provided with a second rectangular protrusion, the front end surface of the positioning bracket 14 bottom is provided with a second rectangular groove that matches the second rectangular protrusion, and the second rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com