Silicone nozzle with spatula function

A technology of silicone and nozzles, which is applied to the device and coating of the surface coating liquid, which can solve the problems of inability to apply in various construction positions, hinder the nozzle end, and poor construction, so as to achieve a beautiful construction surface and improve Accessibility, beautiful appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

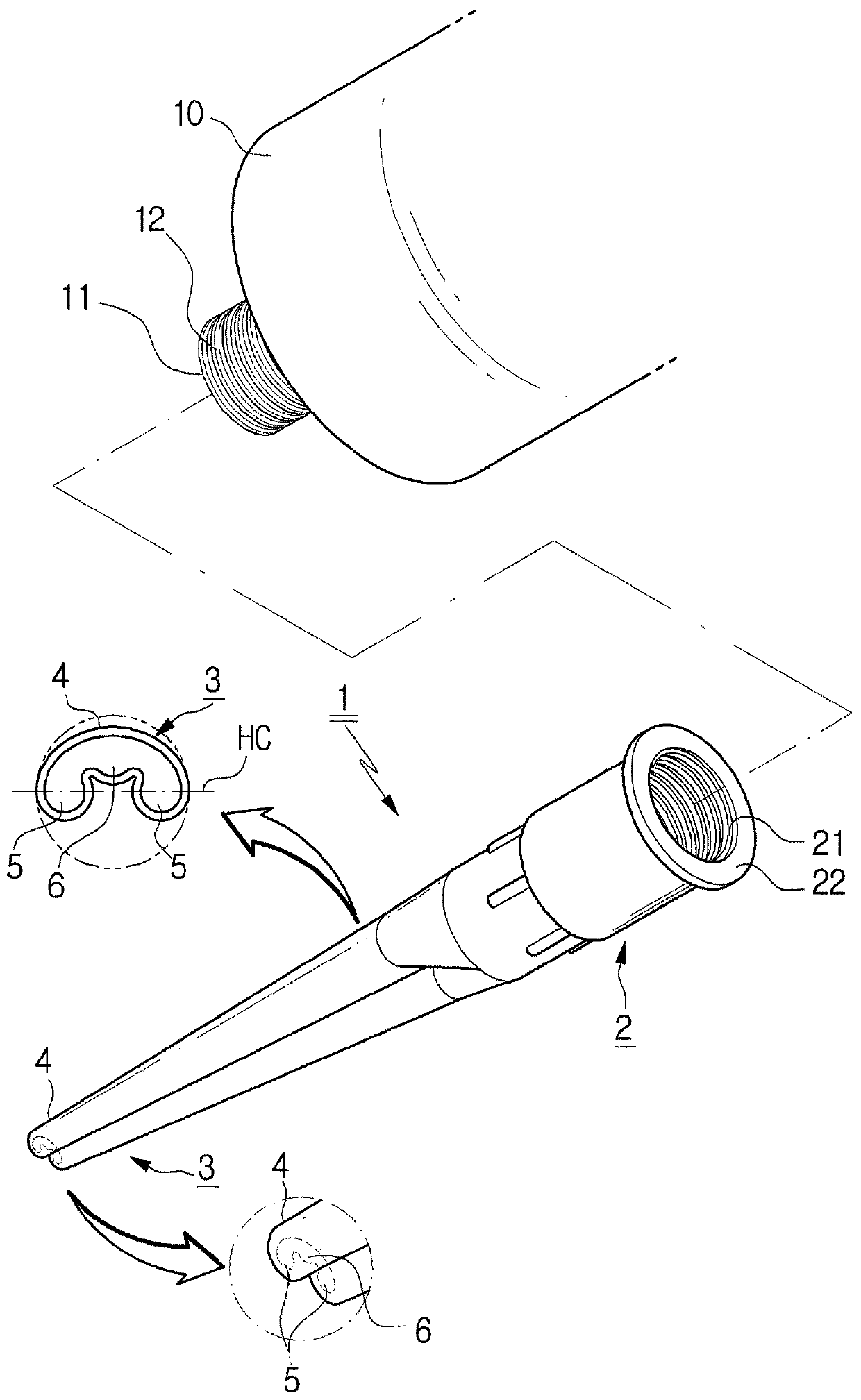

[0025] The present invention relates to a silicone nozzle 1. The above-mentioned silicone nozzle 1 is used to combine with a joint portion 11 formed protrudingly in front of a silicone tube 10. After the silicone tube 10 is installed in a silicone gun, silicon is discharged through the silicone gun. Silicone inside the ketone tube 10 to evenly apply silicone to the construction site, with the following attached Figure 1 The present invention will be described in detail.

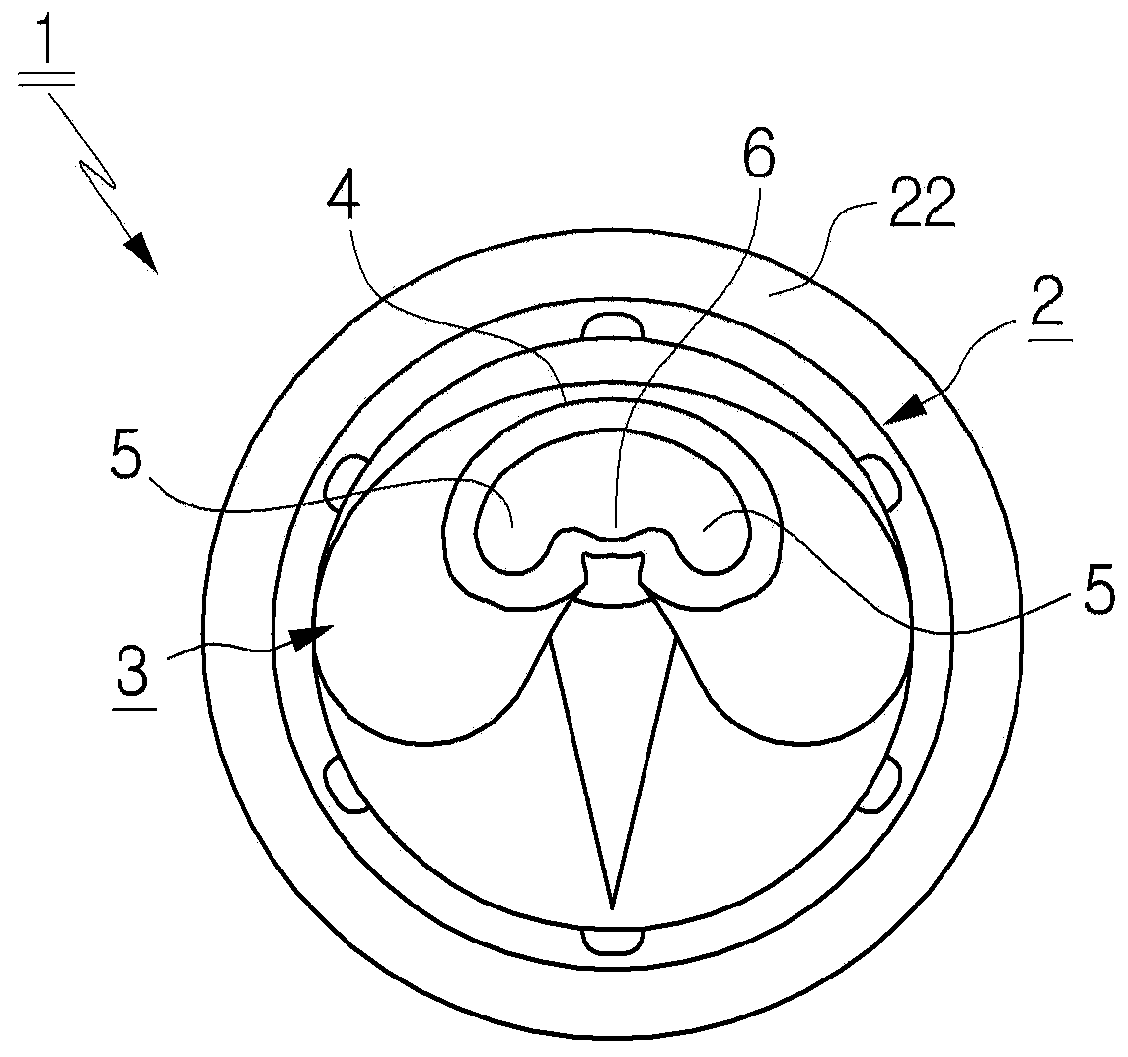

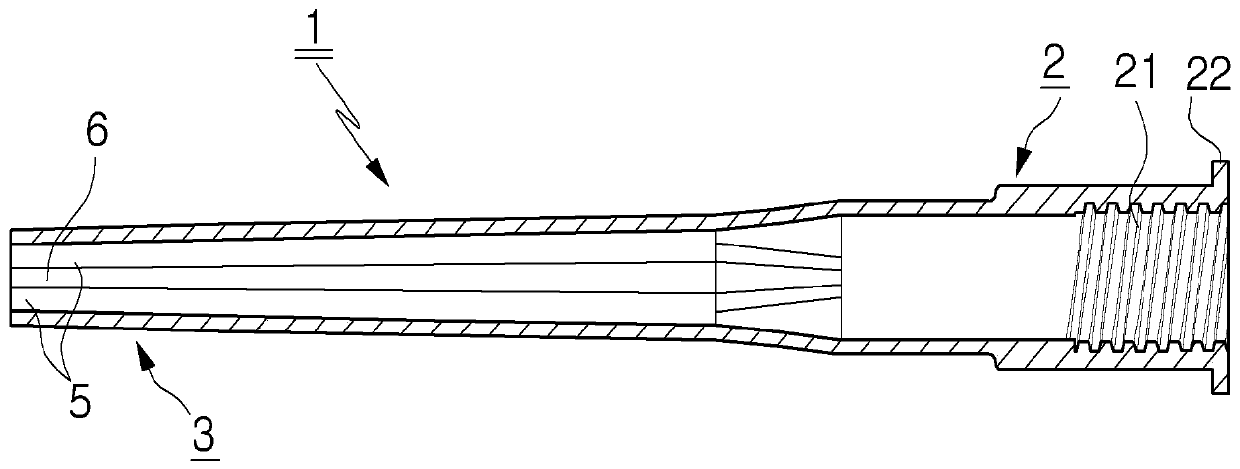

[0026] Such as Figure 1 to Figure 4 As shown, the above-mentioned silicone nozzle 1 of the present invention is a preferred example. Most of the above-mentioned silicone nozzle 1 is formed by the discharge pipe body 3, and is combined with the joint portion 11 protrudingly formed in front of the silicone pipe 10. On the rear inner surface, the nut 21 screwed to the bolt 12 formed on the joint part 11 of the silicone tube 10 is formed on the inner surface, as described above, forming a joint tube of the fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com