Brick carrying handcart with tension force adjusting function

A technology for tension adjustment and trolleys, applied to trolleys, single-axis trolleys, motor vehicles, etc., can solve the problems of action lever flipping, floor structure opening, etc., to achieve the effect of reducing wheel spacing, increasing safety, and improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

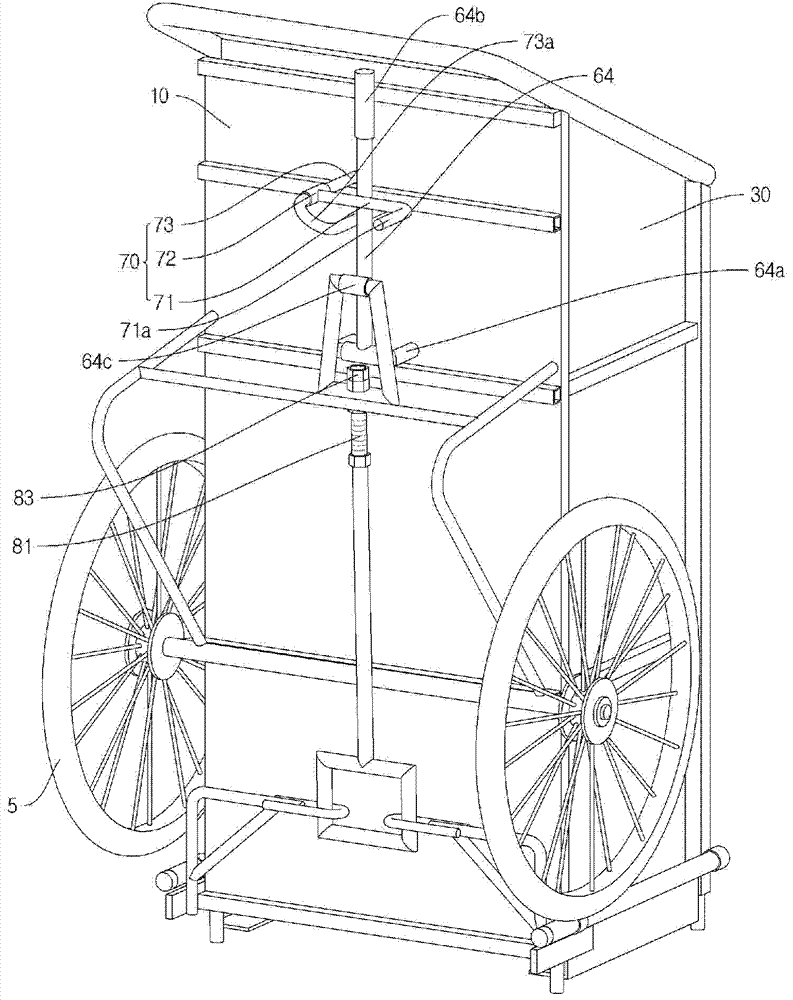

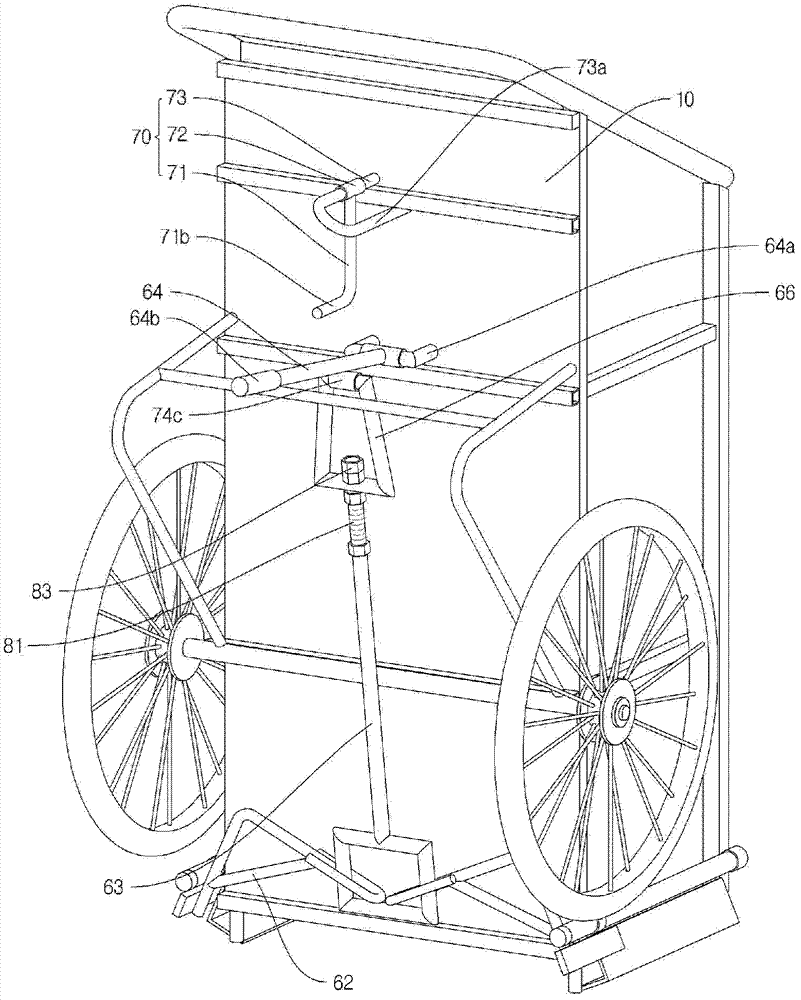

[0043] A kind of brick carrying trolley with tension adjustment function of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0044] Such as Figures 1 to 4 Shown, the brick carrying trolley with tension adjustment function of the present invention comprises:

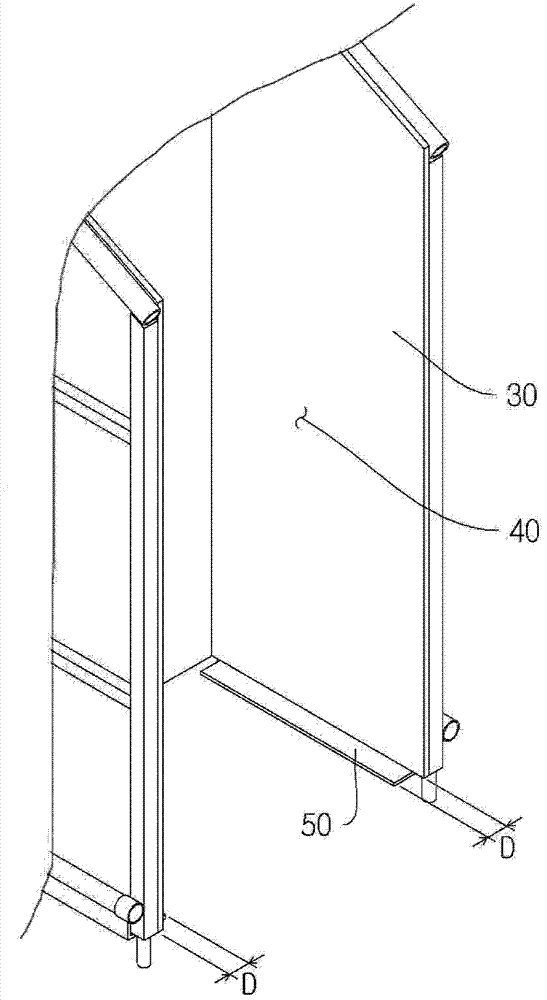

[0045] Including the wheel 5, it also includes: a brick receiving part 40, which is formed by the rear wall plate 10 and two side wall plates 30, and the front part of the brick receiving part 40 is open;

[0046] Two bottom plate structures 50 are used to close or open the brick support area D on both sides except the unloading space in the center of the bottom plate of the brick receiving part 40;

[0047] The action part is used to expand the bottom plate structure 50 to both sides;

[0048] The action unit includes:

[0049] A pair of rotating shafts 61, which are installed in the bracket B1 arranged outside the lower part of the side wall plate 30 and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com