Drum of drum type washing machine

A drum washing machine and drum technology, applied in the drum field of drum washing machines, can solve the problems of weak joint rigidity, damage to clothes, difficulty in application of joints or use of high-speed and large-capacity drums, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Preferred embodiments of the present invention will now be described with reference to the above-mentioned drawings, in which like numerals represent like parts. The details shown herein are merely illustrative examples of embodiments of the invention and are intended to provide what is believed to be the most helpful and understandable explanation of the principles and concepts of the invention. At this point, no attempt is made to give more detailed structural details of the invention than are necessary for a basic understanding of the invention, and the description in conjunction with the accompanying drawings will make it clear to those skilled in the art how to implement the invention in practice. Several forms.

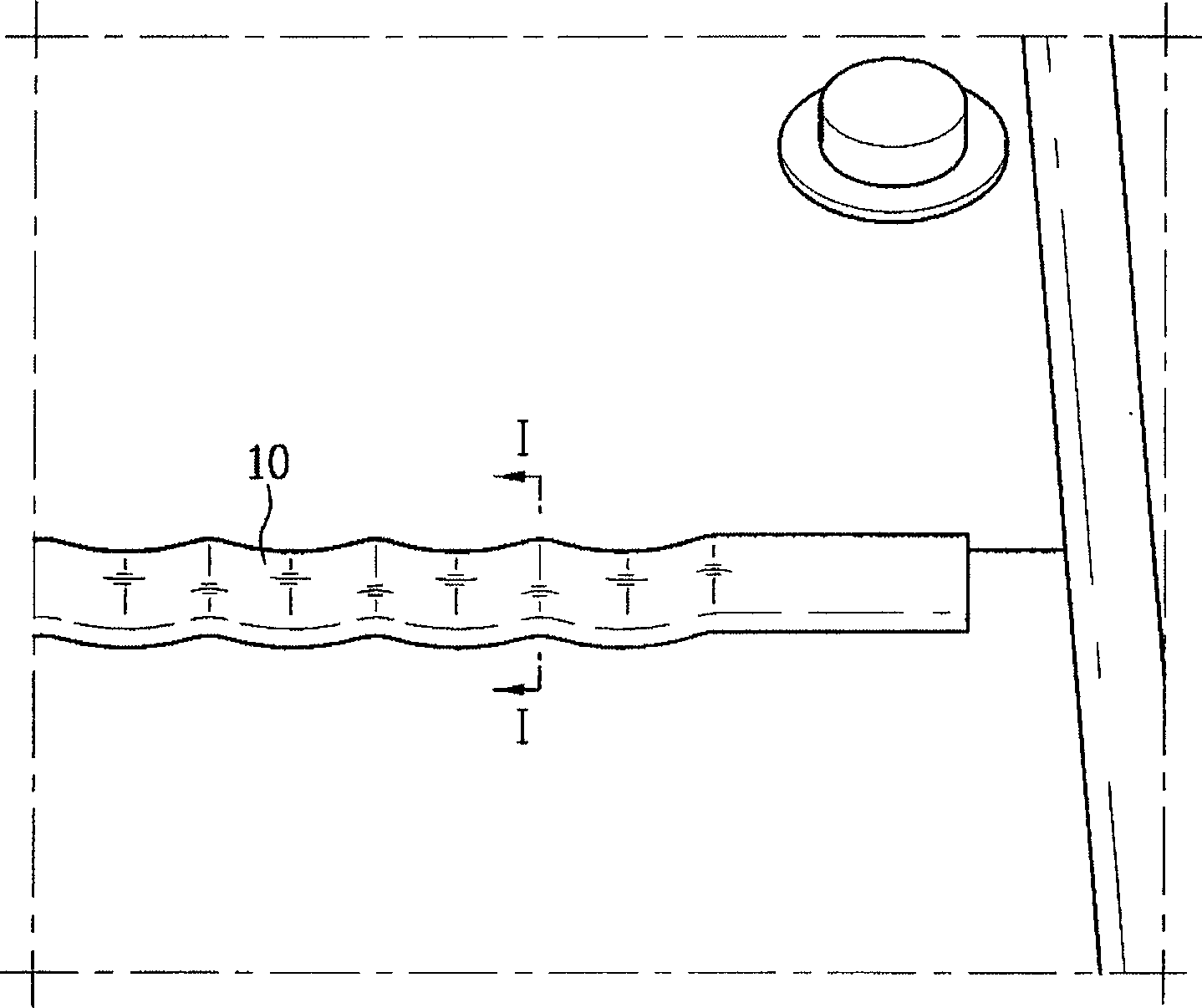

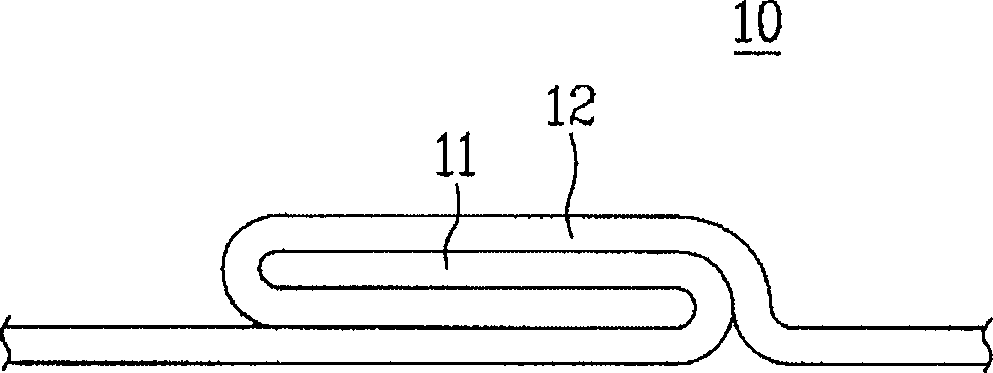

[0050] will refer to Figure 6 The drum of the drum washing machine according to the first embodiment of the present invention will be described.

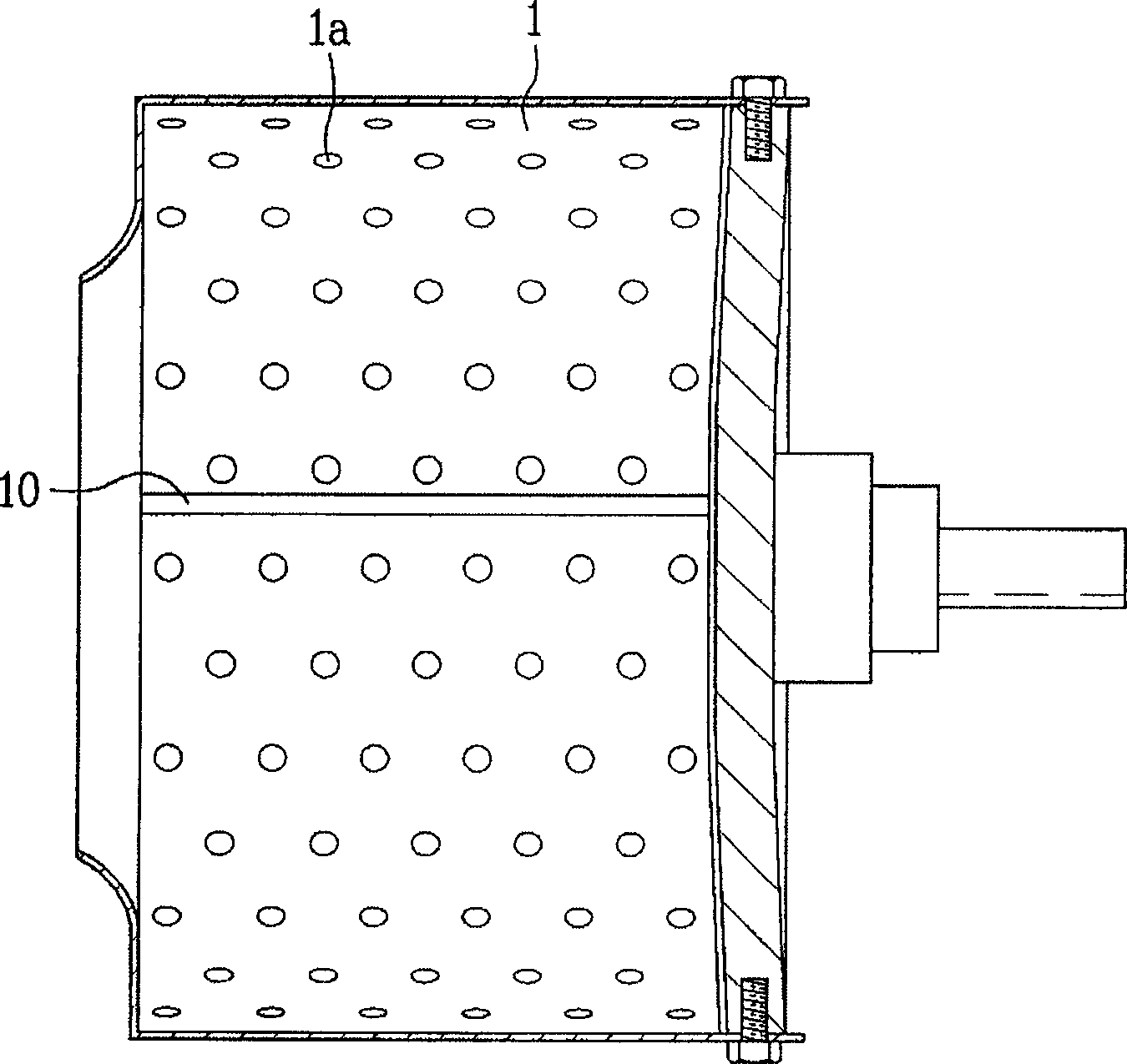

[0051] The drum includes: a cylinder 100 having a joint 110, and two circumferential ends of the cylinder a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com