Hydraulic correction mechanism of lace machine length-direction component

A technology of correction mechanism and lace machine, which is applied in the field of textile equipment, can solve the problems of affecting production progress, high technical proficiency of processing workers, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

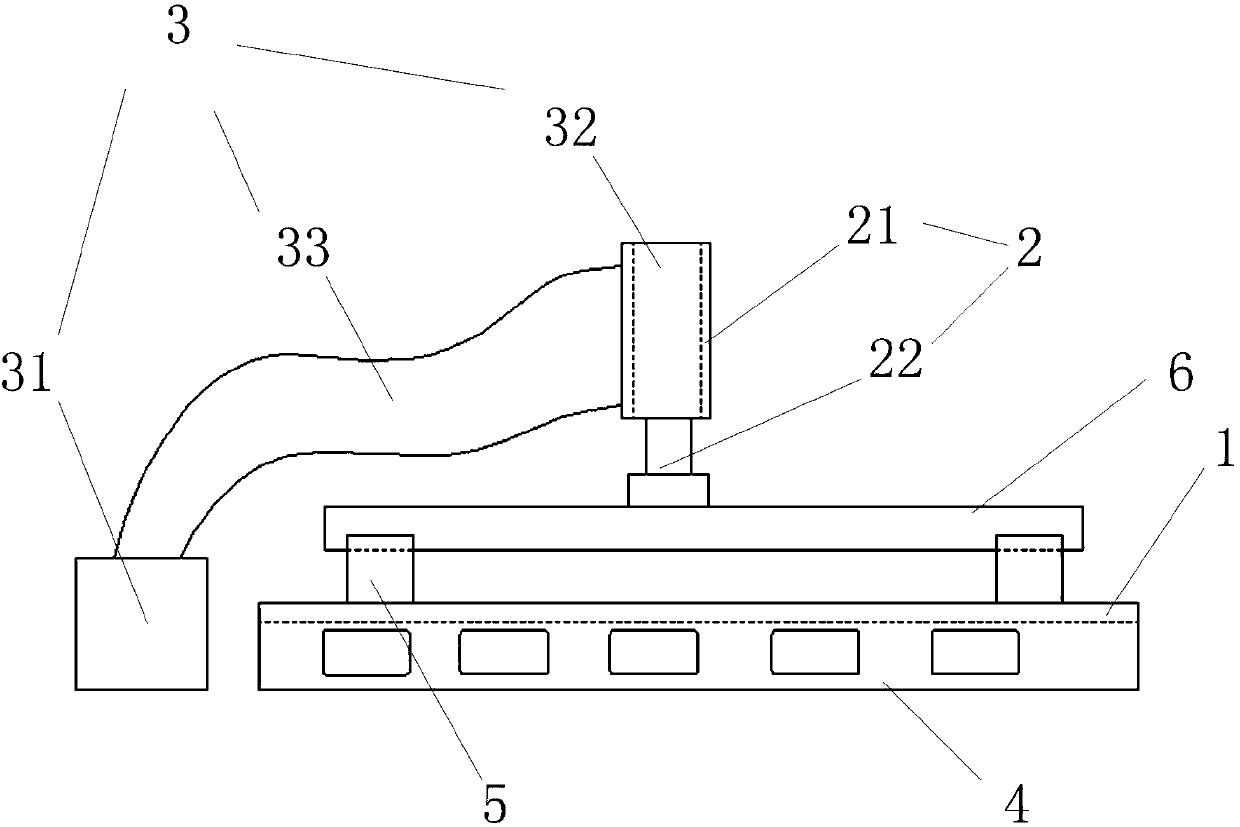

[0017] As the first embodiment of the present invention, a hydraulic correction mechanism for the length of the lace machine is proposed, such as figure 1 As shown, it includes: a long workbench 1, a calibration device 2 and a pressure supply device 3, the calibration device 2 is arranged on the top of the long workbench 1, and the pressure supply device 3 is arranged on the side of the long workbench 1, and is connected with the long workbench 1 Connect to workbench 1. The length of the longitudinal workbench 1 is 9 meters, which can completely place the longitudinal workpiece 6 of the lace machine, so that the longitudinal workpiece 6 will not be deformed in multiple sections due to operational problems during the correction process. The bottom of the long workbench 1 is provided with a base 4 with a plurality of through holes, which not only ensures the stability of the workbench, but also reduces the overall weight and facilitates transportation. In this embodiment, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com