An intelligent box repair system

An intelligent, bottom-plate technology, applied in the field of containers, can solve problems such as improper control of artificial heating stability, reduced service life of container bottom beams, ignoring precision requirements, etc., and achieve the effects of reduced operation difficulty, increased number of heating parts, and reduced proficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

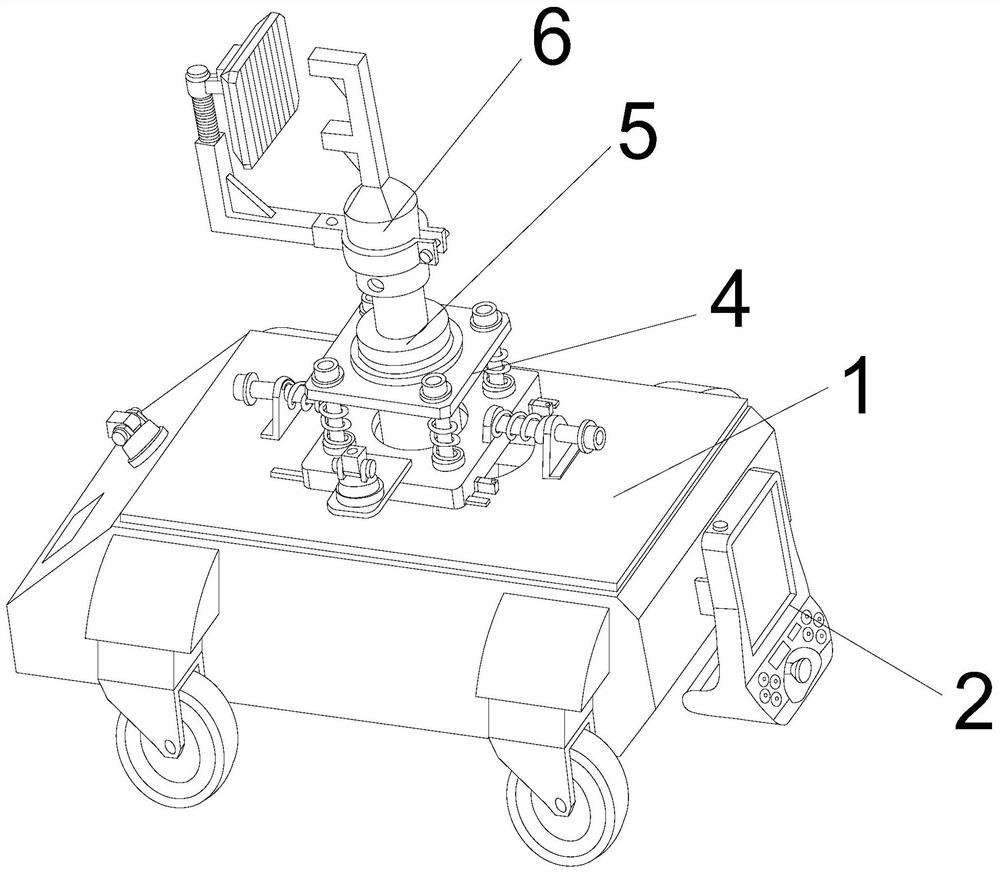

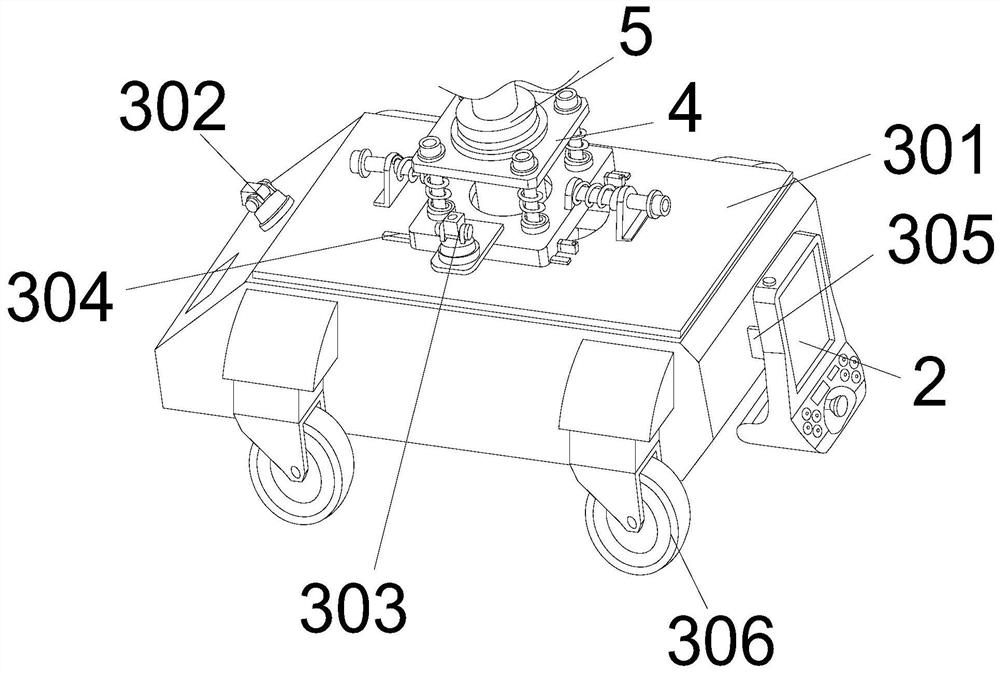

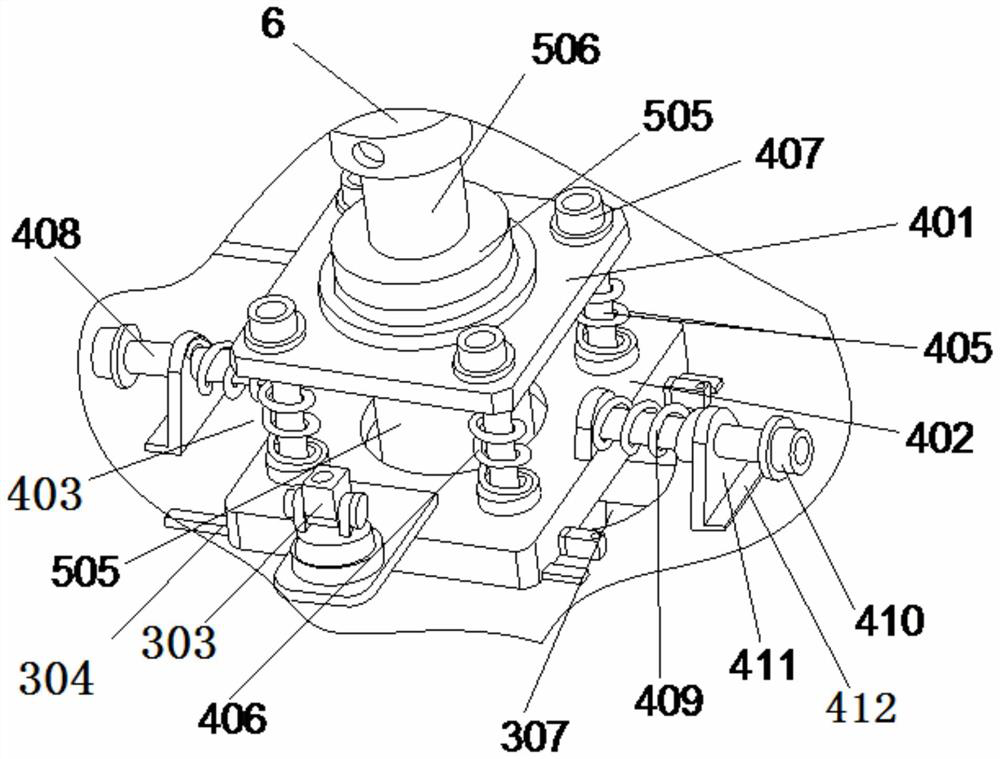

[0046] see Figure 1-Figure 8 In this embodiment, an intelligent box repair system includes a box repair robot 1 and a control handle 2 for controlling the box repair robot 1, the control handle 2 is wirelessly connected to the box repair robot 1, and the box repair robot 1 includes a driving base 3. Balance device 4, jacking device 5 and heating device 6. The balance device 4 includes a top plate 401, a bottom plate 402 and a plurality of elastic members 403. Both the top plate 401 and the bottom plate 402 are provided with notches. Specifically, the The elastic member 403 includes a first guide rod 405, a first spring 406 and a first shaft end fixing cap 407. The first guide rod 405 is arranged and connected to the bottom plate 402 along the perimeter direction of the notch, and is perpendicular to The bottom surface of the bottom plate 402, the first spring 406 is sleeved on the first guide rod 405 and the height is smaller than the height of the first guide rod 405, the bo...

Embodiment 2

[0053] see Figure 9-Figure 16In this embodiment, an intelligent box repair system includes a mechanical arm 8 and a horizontally movable base 9, the mechanical arm 8 is fixedly mounted on the horizontally movable base 9, and the horizontally movable base 9 is arranged in a rectangular shape, and includes two Two relatively short side ends and two relatively long side ends, the two long side ends are symmetrically provided with driving wheels 306, the mechanical arm 8 includes a first mechanical arm 801, a second mechanical arm 802, and the first mechanical arm 802 One end of the arm 801 is rotatably connected to the driving base, the other end of the first mechanical arm 801 is rotatably connected to one end of the second mechanical arm 802, and the other end of the second mechanical arm 802 is movably connected with a fixed clamping device 803, the fixed clamping device 803 is provided with a cutting head 804, or a welding head 805, or a grinding head 806, or a painting head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com