Hinge structure

A hinge structure and hinge technology, applied in the field of hinges, can solve the problems of rusting of springs, affecting the normal use of hinges, disappearance or reduction of self-recovery force, etc., achieving the effects of convenient production and manufacturing, novel structural design and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

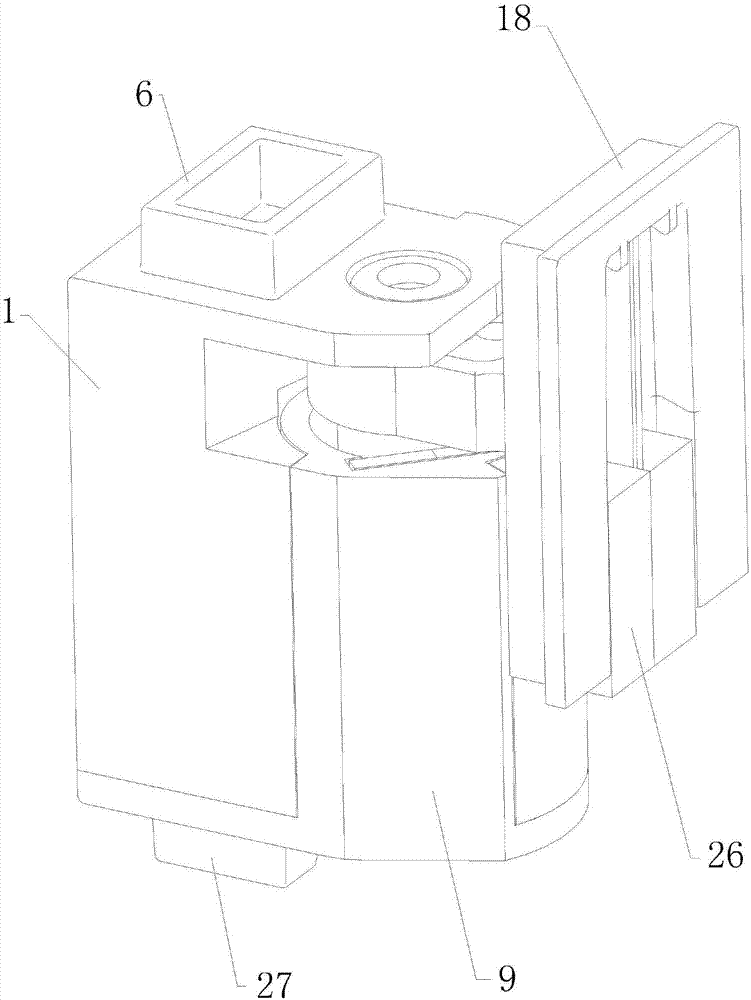

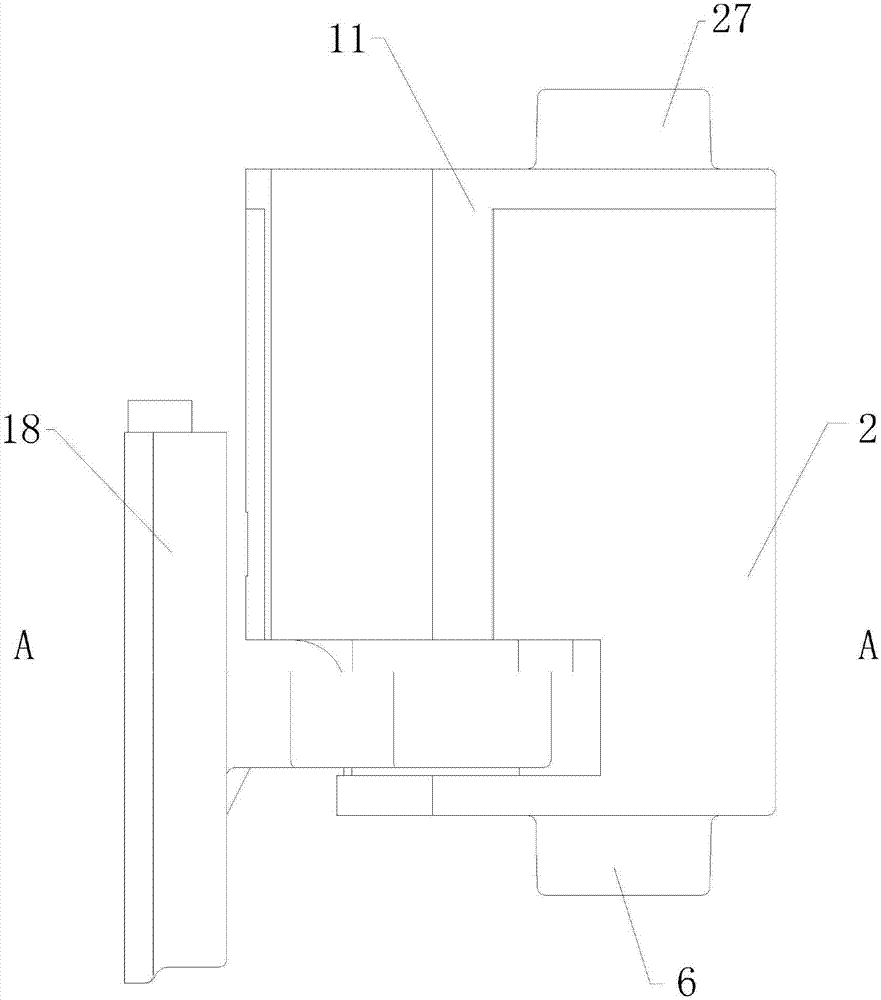

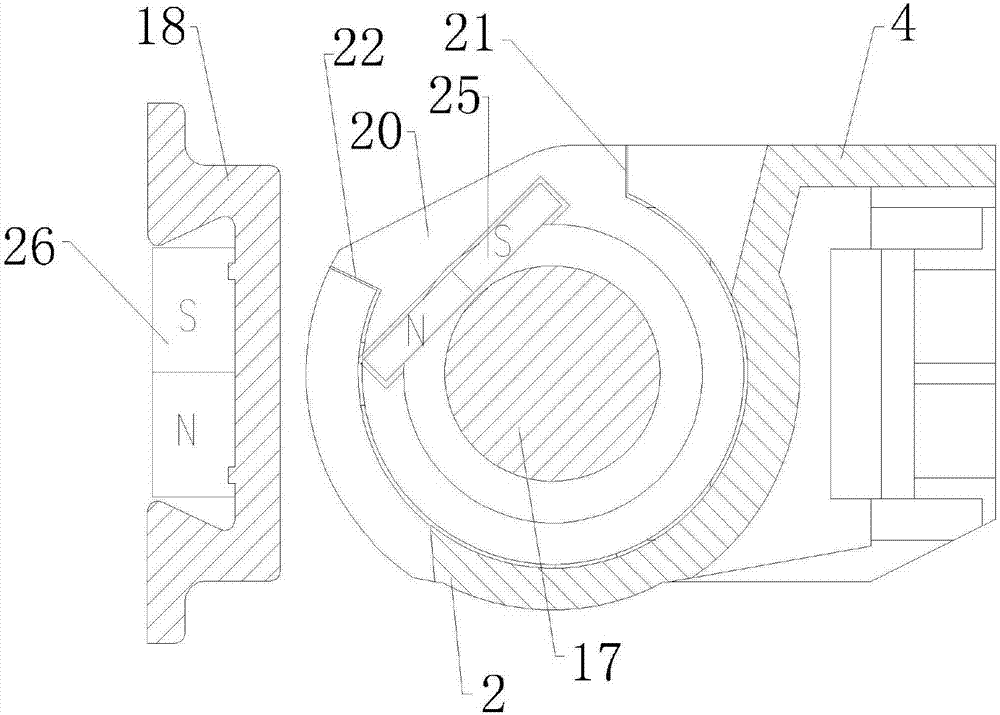

[0025] see Figure 1 to Figure 3 , the hinge structure of the present embodiment is to set a hinge box with a shaft hole inside, one side of the hinge 16 is arranged in the shaft hole with its columnar body 17 rotating and uses the columnar body 17 as the rotating shaft of the hinge 16, and the other side is The connecting plate 18 hanging outside the hinge box is provided with a magnet A 25 and a magnet B 26 respectively in the hinge box body and on the connecting plate 18. The magnetic pole directions of the magnet A 25 and the magnet B 26 are consistent and both rotate along the hinge 16. The tangential direction of the magnet A 25 and the magnet B 26 interact to provide a torque to rotate the hinge 16 .

[0026] Wherein, the hinge box is composed of a hinge box cover 1 and a hinge box seat 9 connected to each other, specifically:

[0027] see Figure 5 to Figure 7 , the hinge box cover 1 is provided with a tubular sleeve 2, which has a through hole 3 inside, and the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com