Thermohydraulic experiment system related to the interaction between melt and coolant

An experimental system and thermal hydraulic technology, applied in the field of experimental systems, can solve the problems of limited experimental results, low experimental efficiency, and low experimental temperature, and achieve the effect of improving experimental efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

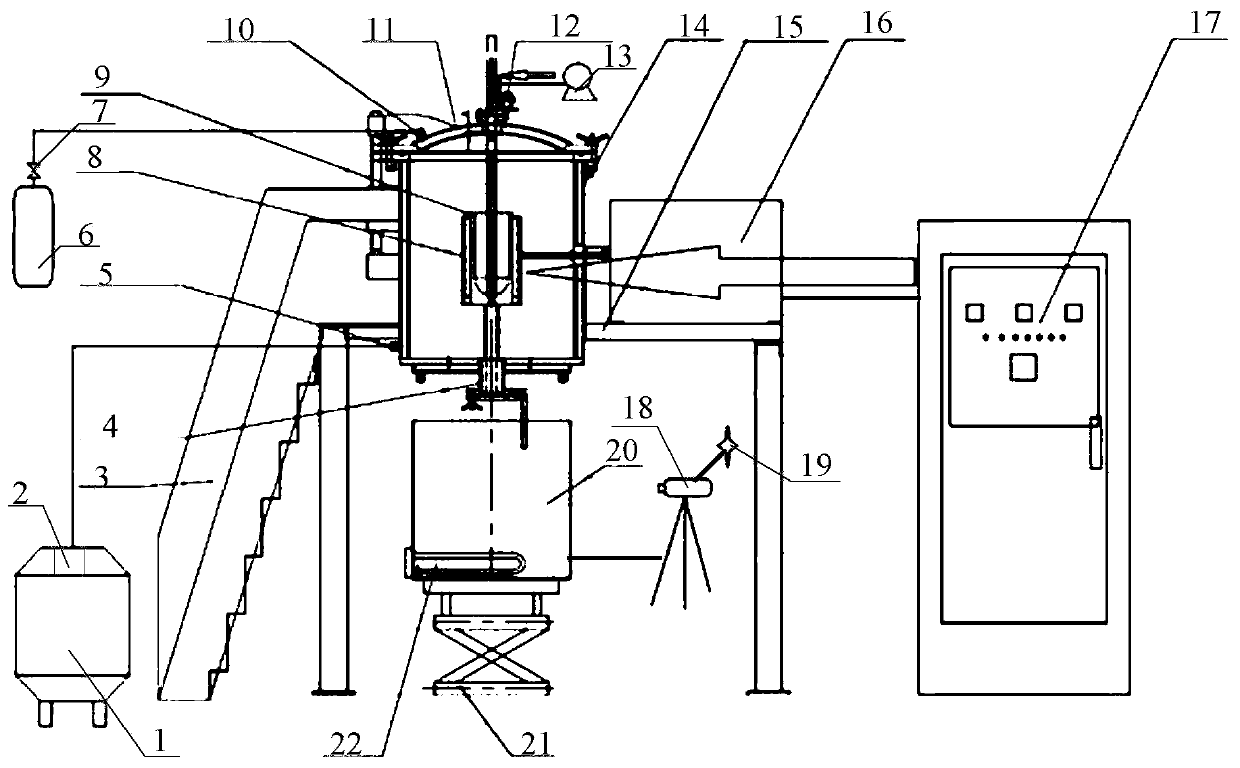

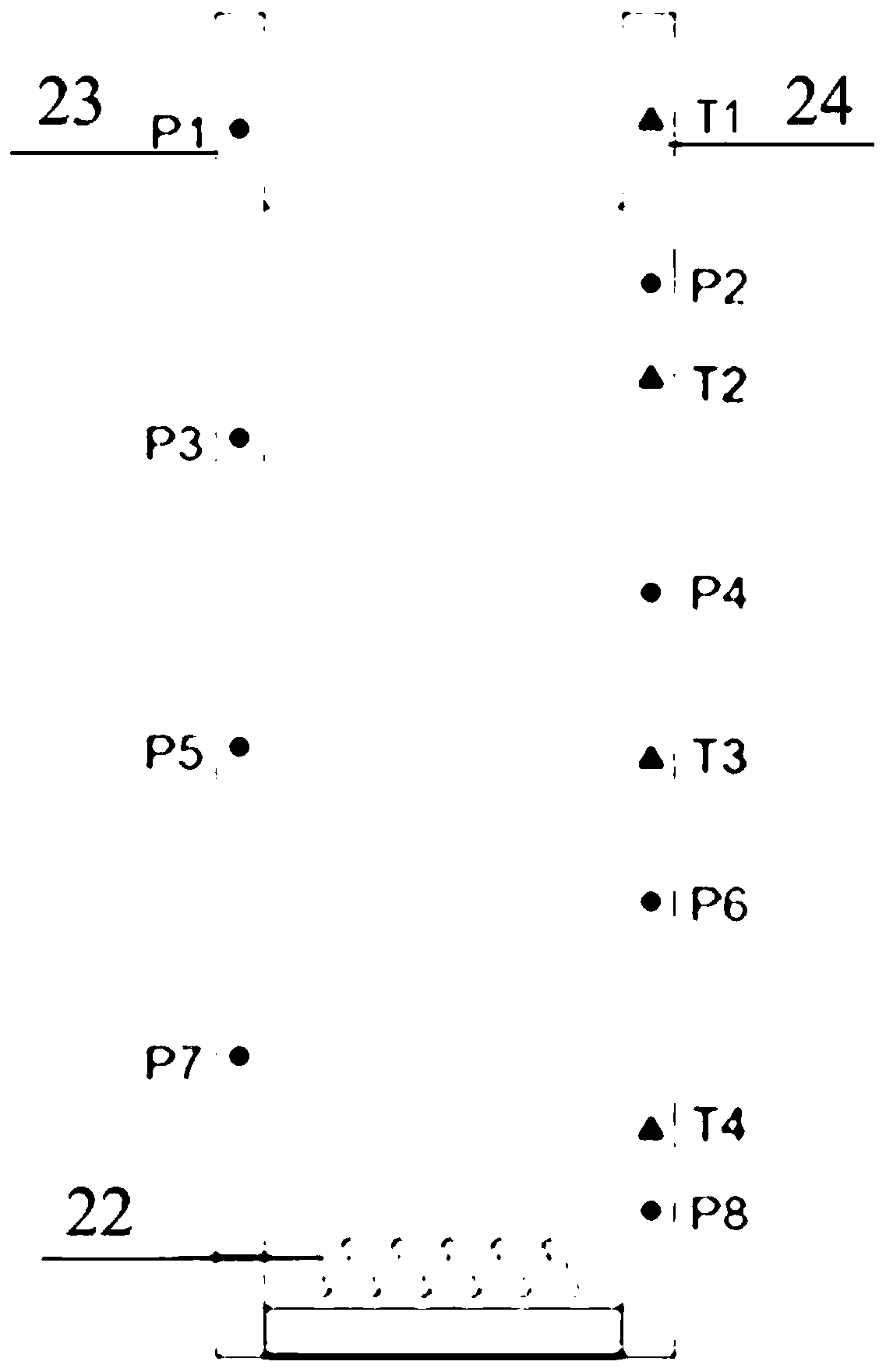

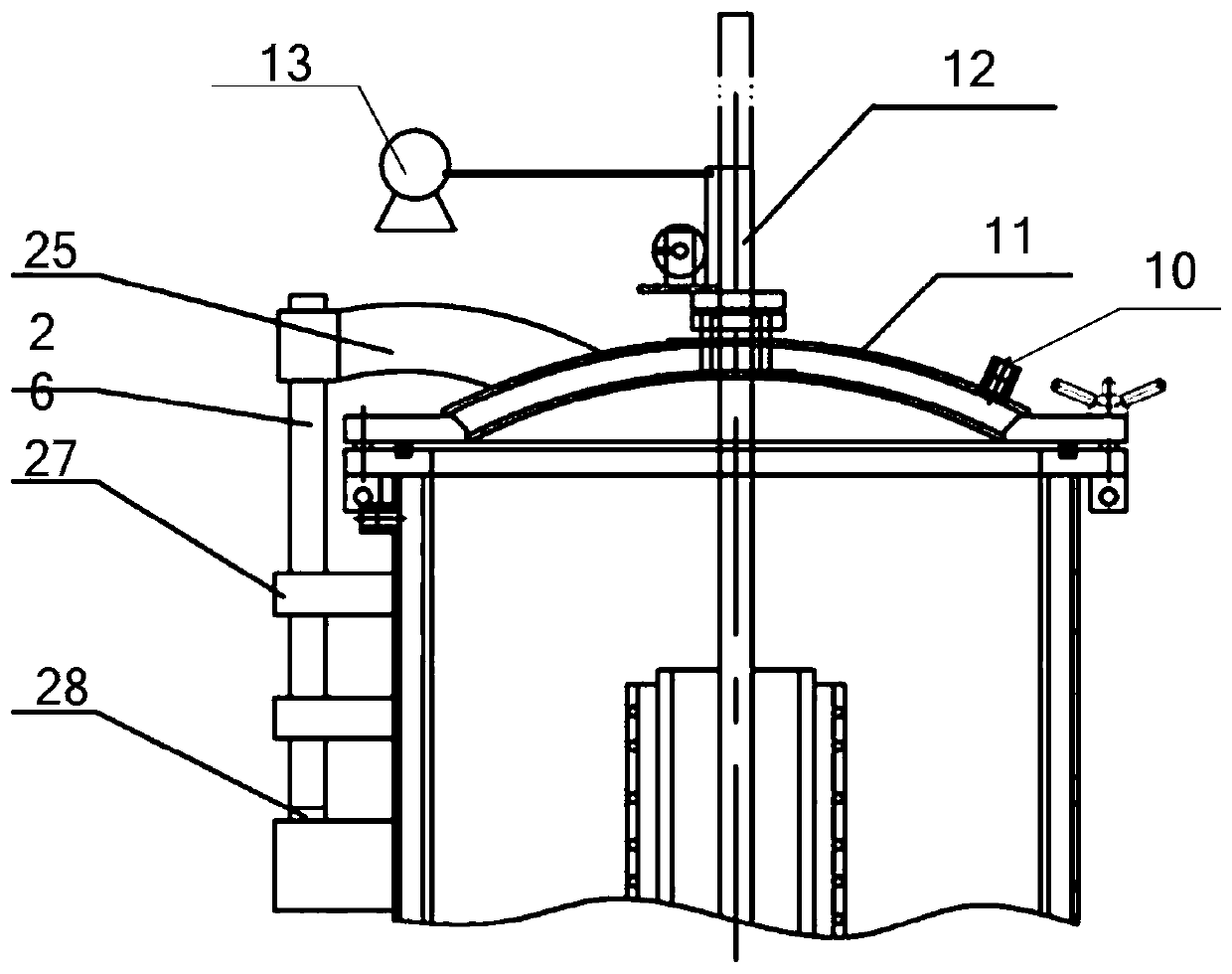

[0029] Such as Figure 1 to Figure 5 As shown, the thermal-hydraulic experimental system related to the interaction between the melt and the coolant of the present invention includes an experimental stainless steel platform, a high-temperature furnace system, a shielding gas system, a cooling system, a heating control system, an experimental water tank system, a high-speed camera system, and a lifting platform. :

[0030] The experimental stainless steel platform 15 is divided into upper and lower layers. The upper layer is paved with stainless steel plates, surrounded by stainless steel guardrails, and the lower layer is welded and sealed with stainless steel plates to form a relatively airtight space. Two doors are reserved for entry and exit. 3 up and down;

[0031] The high-tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com