Resistive random access memory with planar structure and manufacturing method thereof

A technology of resistive memory and planar structure, applied in the direction of electrical components, etc., to achieve the effect of simple method, saving raw material cost, and high mobility characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

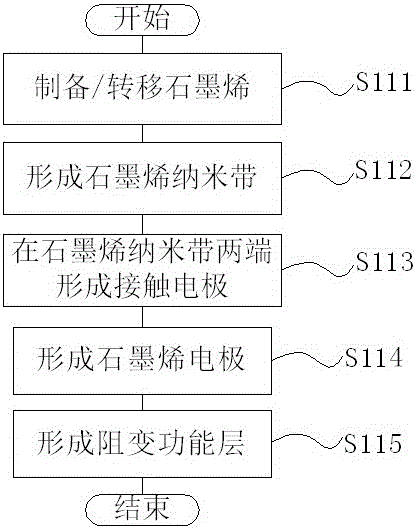

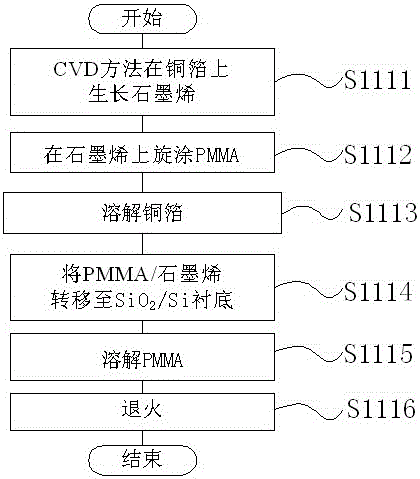

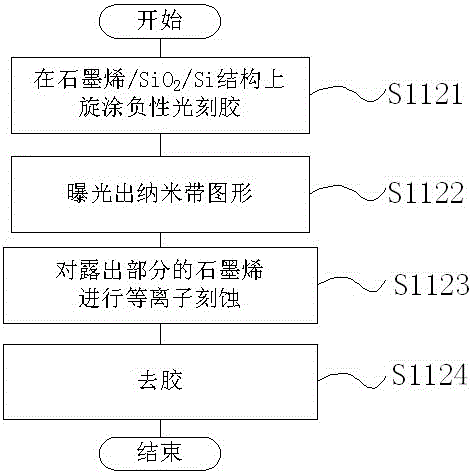

[0030] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings, in which like elements are denoted by like reference numerals. The embodiments described below are exemplary, and in order to simplify the disclosure of the present invention, components and arrangements of specific examples are described below. Of course, these are only examples for the purpose of explaining the present invention and should not be construed as limiting the present invention. In addition, the present invention provides various specific examples of processes and materials, but the invention may be practiced without these specific details, as will be understood by those skilled in the art. Unless otherwise specified below, each part of the device can be implemented using processes and materials known in the art. Additionally, configurations described below in which a first feature is "on" a second feature may include embodiments where the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com