A propellant step-by-step neutralization spray spray system and control method

A spray system, step-by-step technology, applied in the control/regulation system, non-electric variable control, simultaneous control of multiple variables, etc., can solve the problems of insufficient absorption capacity, reduce the probability of accidents, etc. The effect of utilization rate and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

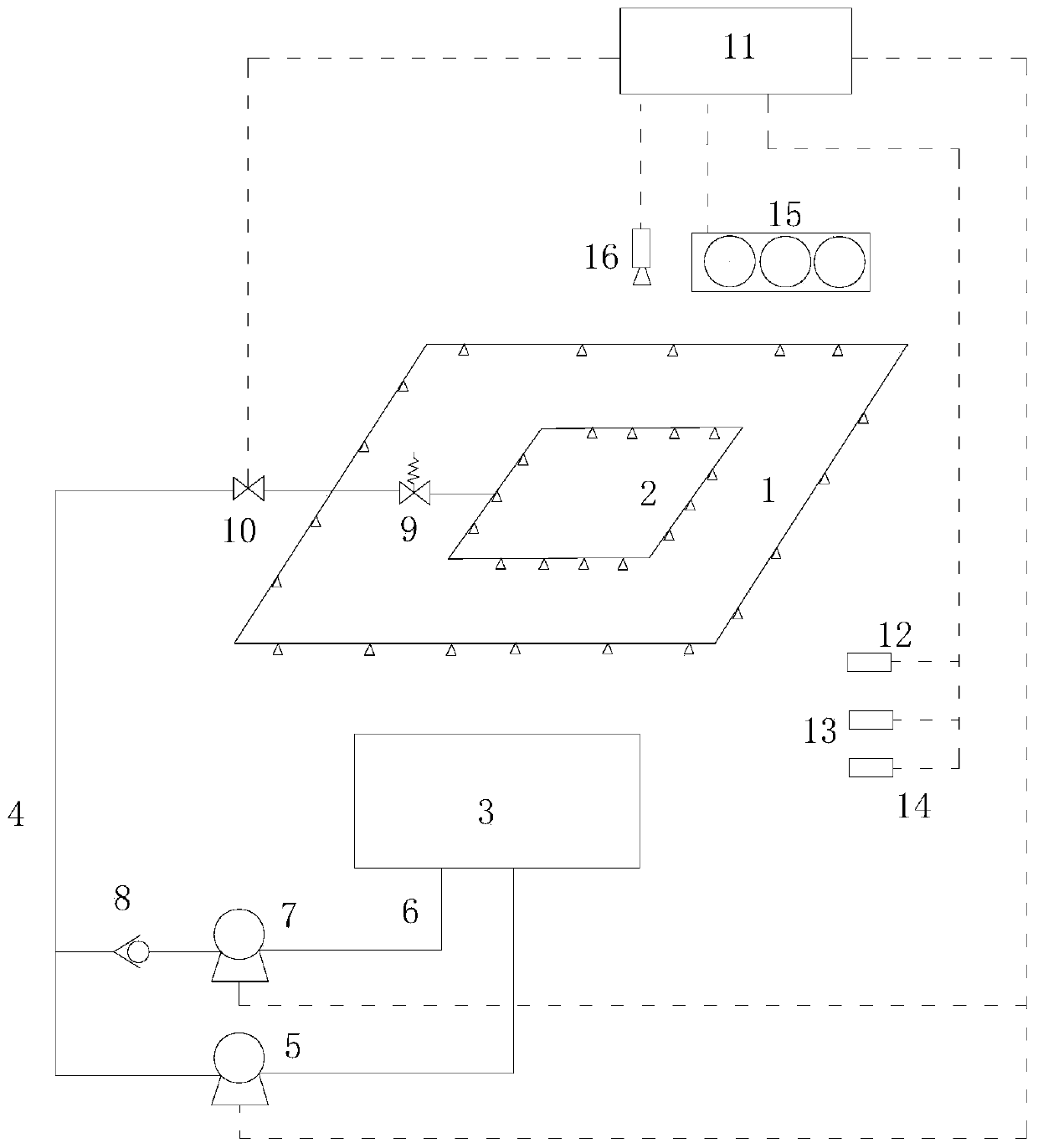

[0032] Such as figure 1 As shown, a propellant step-by-step neutralization spray spray system of the present invention includes an absorption liquid storage tank 3, and a liquid delivery pipe 4 connected to the absorption liquid storage tank 3, and the upper edge of the liquid delivery pipe 4 The liquid delivery direction is respectively connected with the first water pump 5, the spray pipe 1 and the suction spray pipe 2. It is characterized in that the part of the liquid delivery pipe 4 located between the spray pipe and the spray pipe 2 is provided with a pressure valve 9, so A second liquid delivery pipe 6 is also connected between the absorption liquid storage tank 3 and the liquid delivery pipe 4, the second liquid delivery pipe 6 is provided with a second water pump 7, and the second liquid delivery pipe 6 is provided with Pressure valve 9 along the liquid delivery direction.

[0033] This solution uses the liquid delivery pipeline of the existing spray system, which sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com