Epitaxial layer stripping device and stripping method

A technology for stripping devices and epitaxial layers, which is applied in sustainable manufacturing/processing, climate sustainability, and final product manufacturing. Easy entry and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

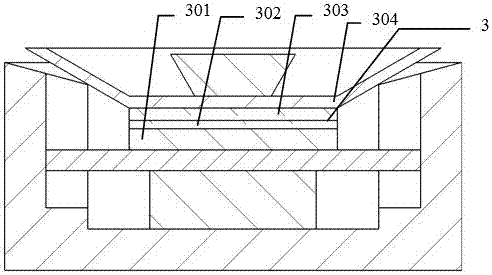

[0027] This embodiment relates to a kind of epitaxial layer stripping device, refer to figure 2 , the part 3 to be stripped in this embodiment mainly includes a substrate 301, a sacrificial layer 302, an epitaxial layer 303 and a support layer 304, and the edge of the support layer 304 extends a part compared to the substrate 301, which is convenient for placing in the box body 2 above the side wall.

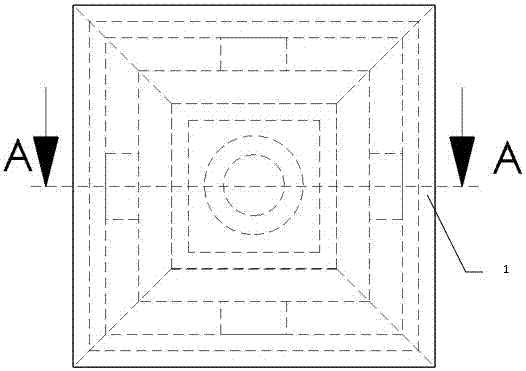

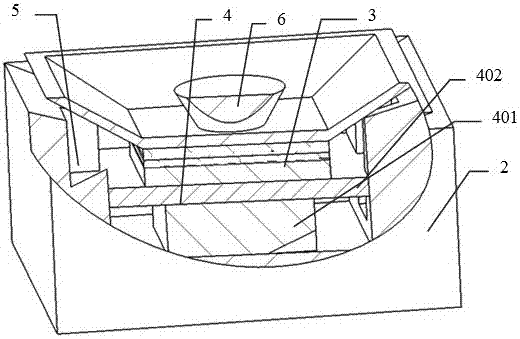

[0028] refer to figure 1 with image 3 The epitaxial layer stripping device 1 includes a box body 2 with an open upper end, the bottom of the box body is provided with an elastic buffer structure 4, and when the stripping part 3 is placed above the elastic buffer structure 4, the edge of the supporting layer 304 of the stripping part 3 is located in the box body 2 side walls.

[0029] Preferably, in this embodiment, the top of the side wall of the box body 2 of the epitaxial layer stripping device 1 has an inward inclined surface along its thickness for better supporting the...

Embodiment 2

[0037] This embodiment relates to a method for peeling off an epitaxial layer, such as figure 2 with image 3 As shown, it is suitable for the epitaxial layer stripping device in the above embodiment, and the specific methods include:

[0038] (1) Place the part 3 to be stripped above the elastic buffer structure 4 at the bottom of the box body 2, insert the light support block 402 into the limit groove 5, and ensure that the light support block 402 is placed horizontally; place the part 3 to be stripped on the light The top of the support block 402, so that the support layer 304 of the part 3 to be stripped is located above the side wall of the box body 2, so that the edge of the support layer 301 is warped and maintains a certain stress;

[0039] (2) Place the compact 6 on the support layer 304 of the part 3 to be stripped, and immerse the entire device 1 to be stripped together with the part 3 to be stripped in an etching solution containing hydrofluoric acid for corrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com