Mining convenient movable wet filtration dust removal system

A dust removal system and mobile technology, applied in the fields of dust prevention, filtration and separation, mining equipment, etc., can solve the problems such as the inability to effectively control the dust concentration, the inability to solve the dust hazard, and the serious physical harm of the roadheader driver. The effect of ensuring the air volume of dust removal, avoiding uneven atomization, and speeding up the peeling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with accompanying drawing.

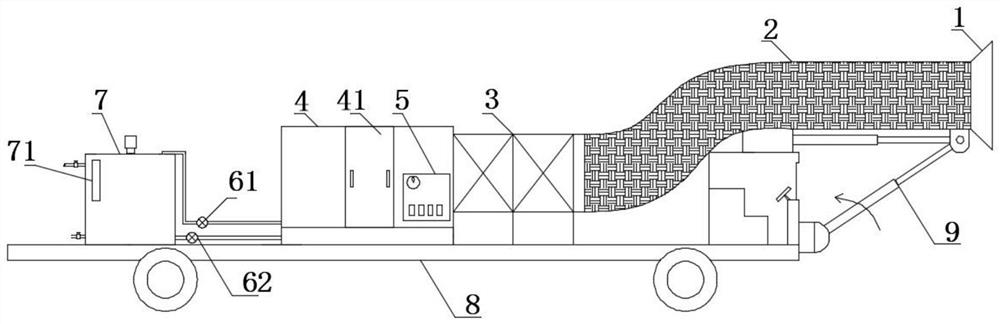

[0065] like figure 1 , figure 2 As shown, this convenient mobile wet filter and dust removal system for mining includes a dust suction assembly, a wet filter dust removal assembly 4 and a purification assembly 7 installed on the mobile trolley 8 in sequence from right to left;

[0066] The dust suction assembly is used to transfer dust to the wet filter dust removal assembly 4;

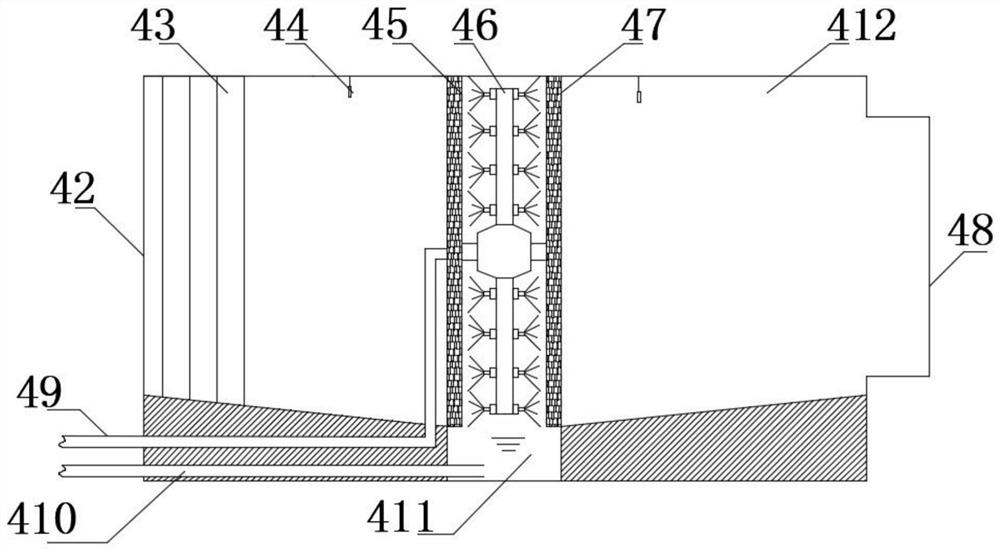

[0067] The wet filter and dust removal assembly 4 includes a dust removal box 412, and filter plates arranged in multiple layers side by side in the dust removal box 412;

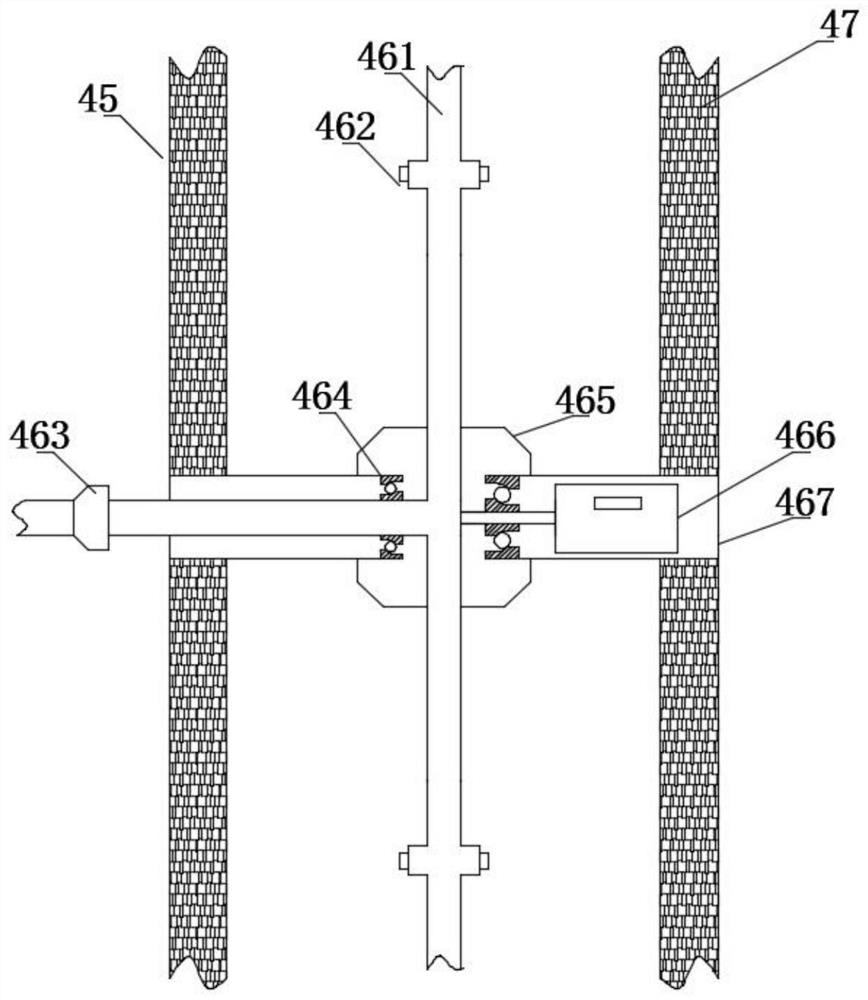

[0068] The aperture of the multi-layer filter plate decreases from right to left, and the middle position is provided with a spray assembly 46 rotating around the horizontal axis, and the lower end of the spray assembly 46 is provided with a sewage chamber 411;

[0069] The spray assembly 46 converts water into water mist an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com