Aluminum wire forming method

An aluminum wire and aluminum metal technology, which is applied in the field of semiconductor manufacturing, can solve the problems of easy drop and reduce the yield of aluminum wire, and achieve the effect of improving the yield and increasing the peeling rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

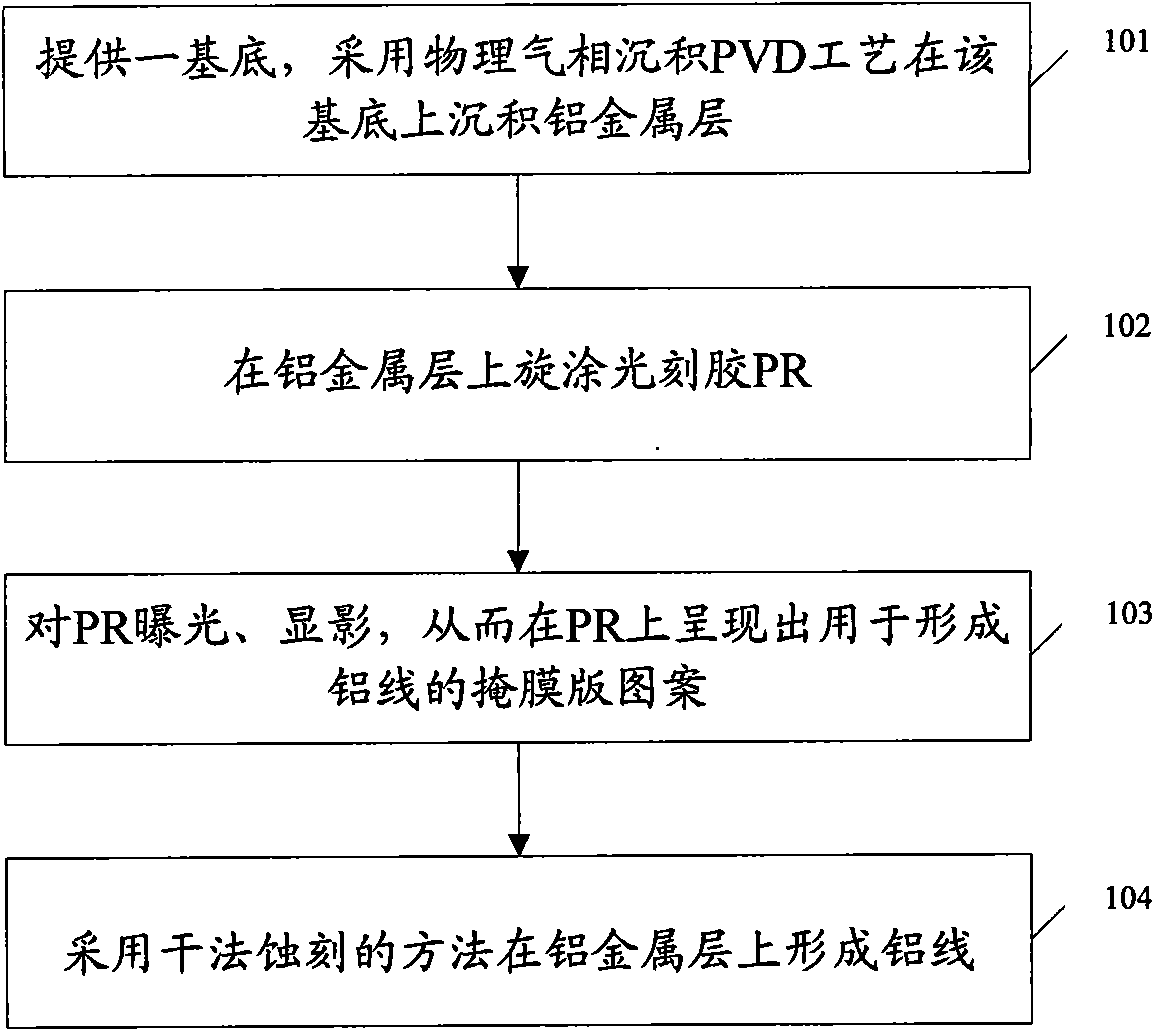

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

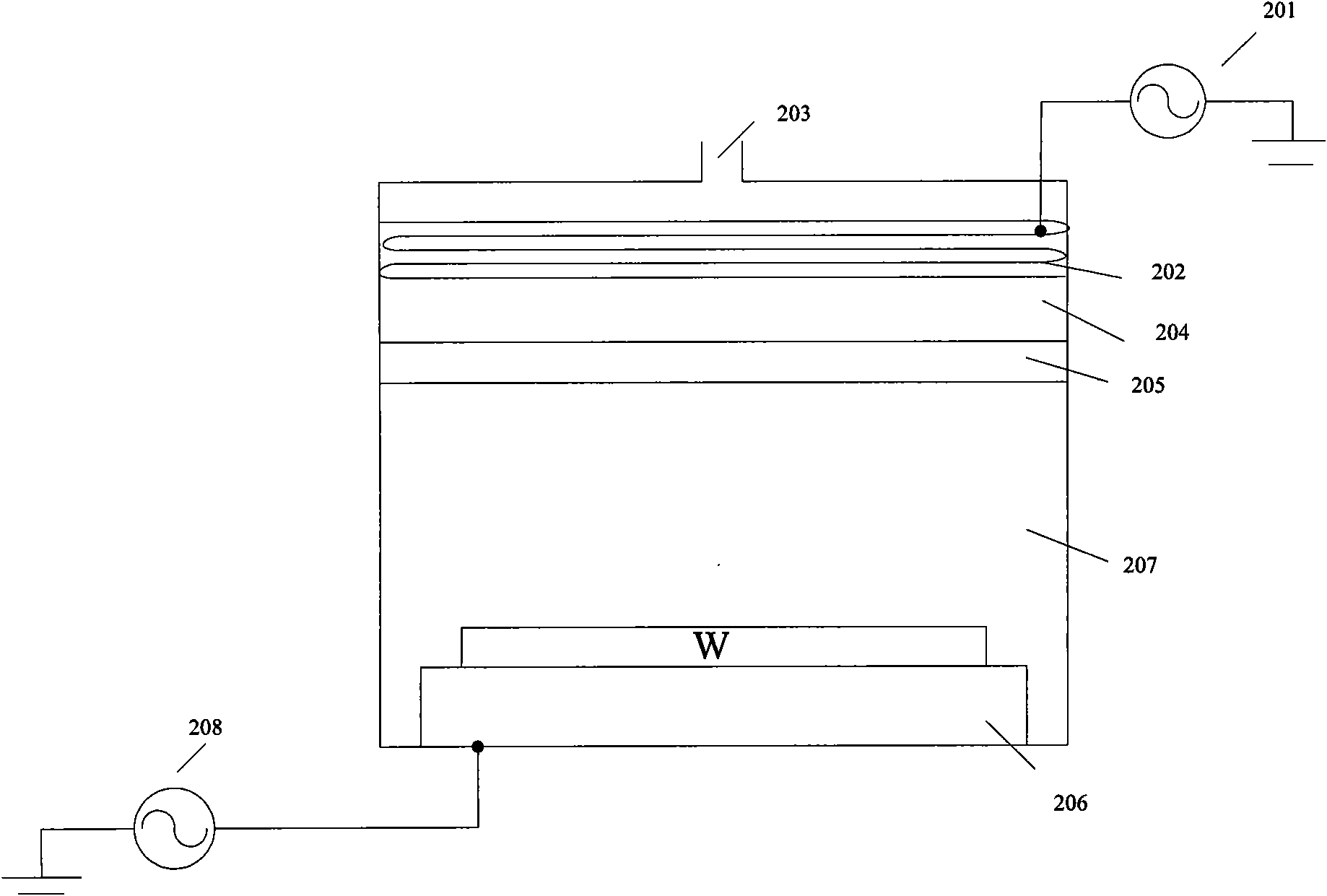

[0022] The core idea of the present invention is: when the aluminum wire is etched, the PR on the surface of the metal aluminum will gradually peel off. Since PR is a sticky substance, the PR will stick to the quartz board. In the present invention, by increasing Large conversion coupling power and / or bias power to achieve the purpose of increasing the peeling rate of PR, so that more PR can be pasted on the quartz reformer, and the viscous PR will firmly stick the polymer to the quartz Alter the plate so that the polymer will not fall off.

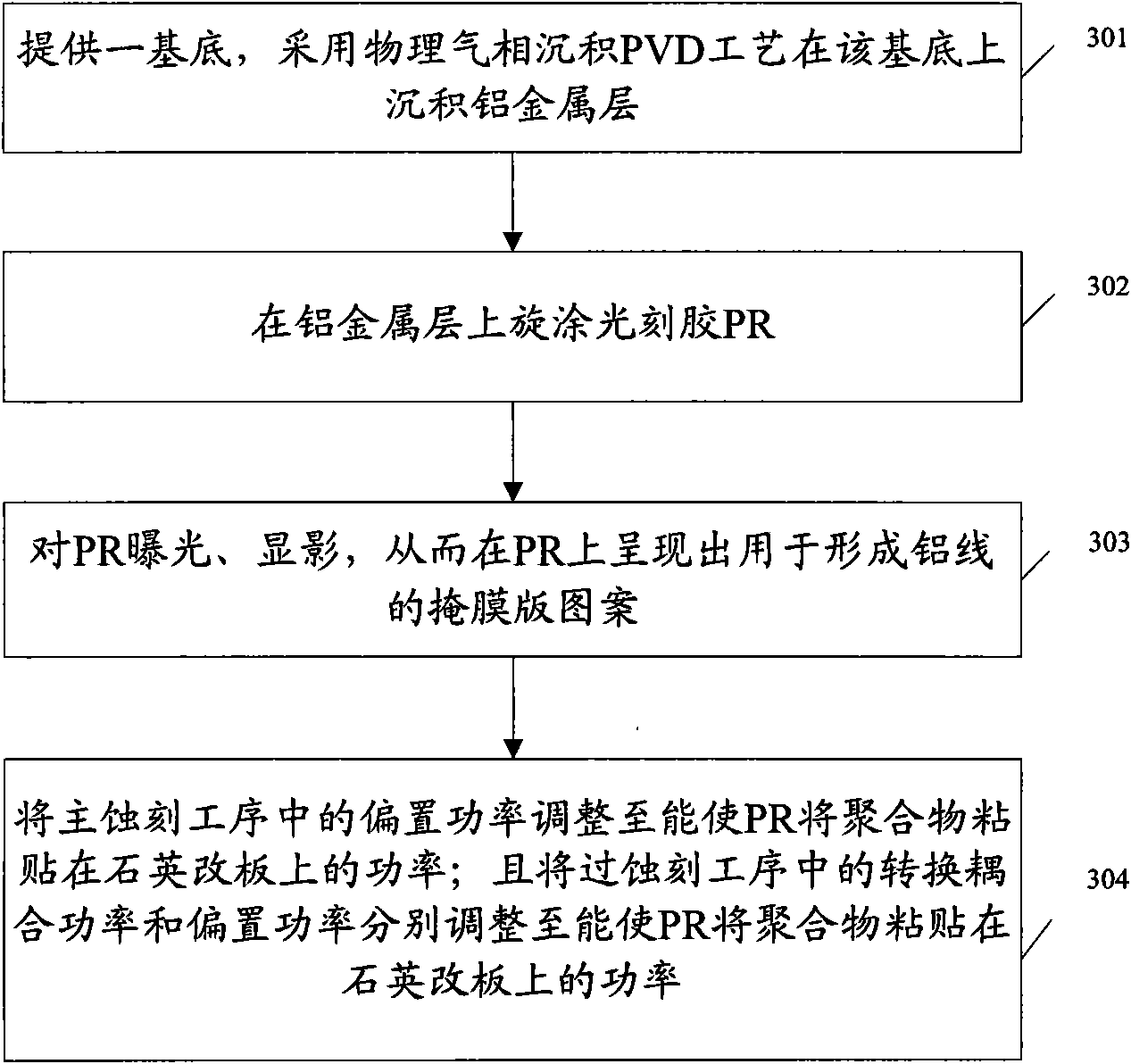

[0023] image 3 It is a flow chart of the aluminum wire forming method provided by the present invention, the method comprising the following steps:

[0024] In step 301, a substrate is provided, and an aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com